Assembling tool of aircraft wing box C-shaped beam and detecting and correcting method of assembling tool

A technology for assembling tooling and wings, which is applied in metal processing, manufacturing tools, workpiece clamping devices, etc., can solve the problems of inability to protect the angle deviation of C-shaped beams, meet design requirements, and inability to include angles, etc., to achieve shortened quality The effect of inspection and assembly cycle, improvement of production efficiency and quality, and avoidance of brittle damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention are described in detail below: this embodiment is implemented on the premise of the technical solution of the present invention, and a detailed implementation manner and specific operation process are given. It should be pointed out that for those of ordinary skill in the art, without departing from the concept of the present invention, several modifications and improvements can be made, and these all fall within the protection scope of the present invention.

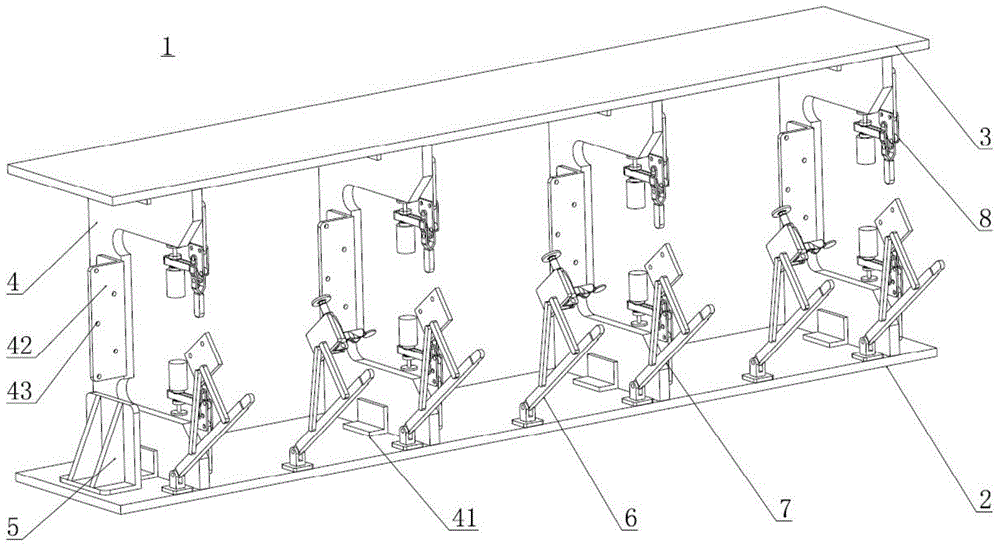

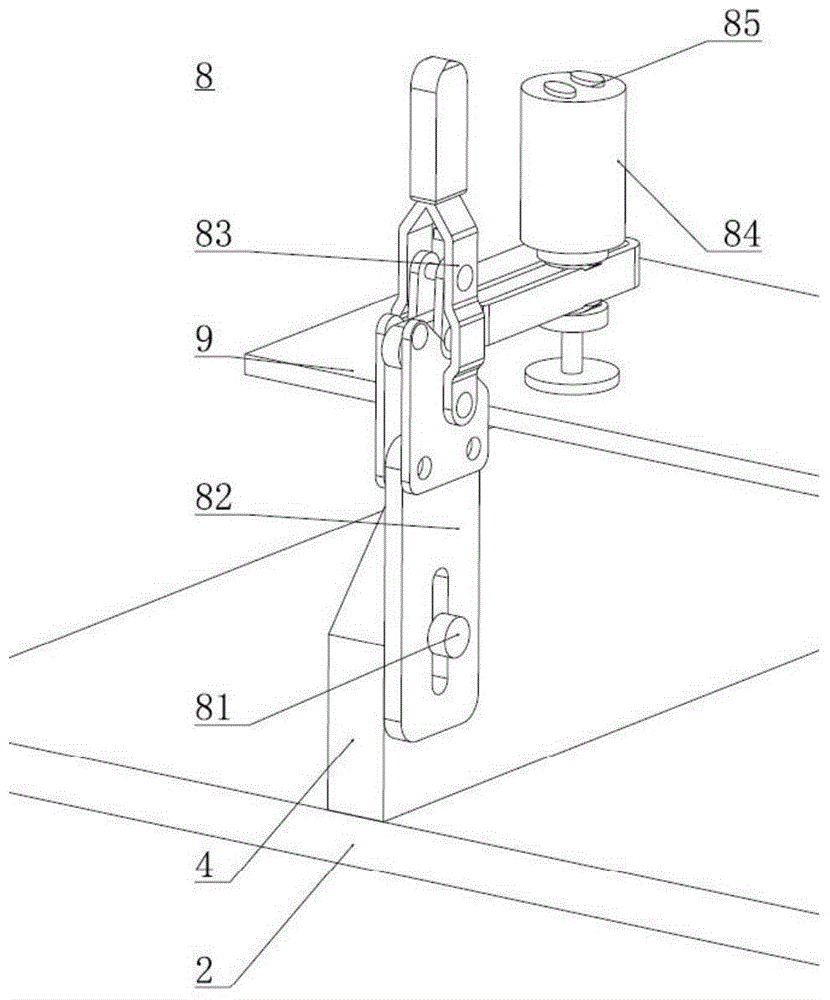

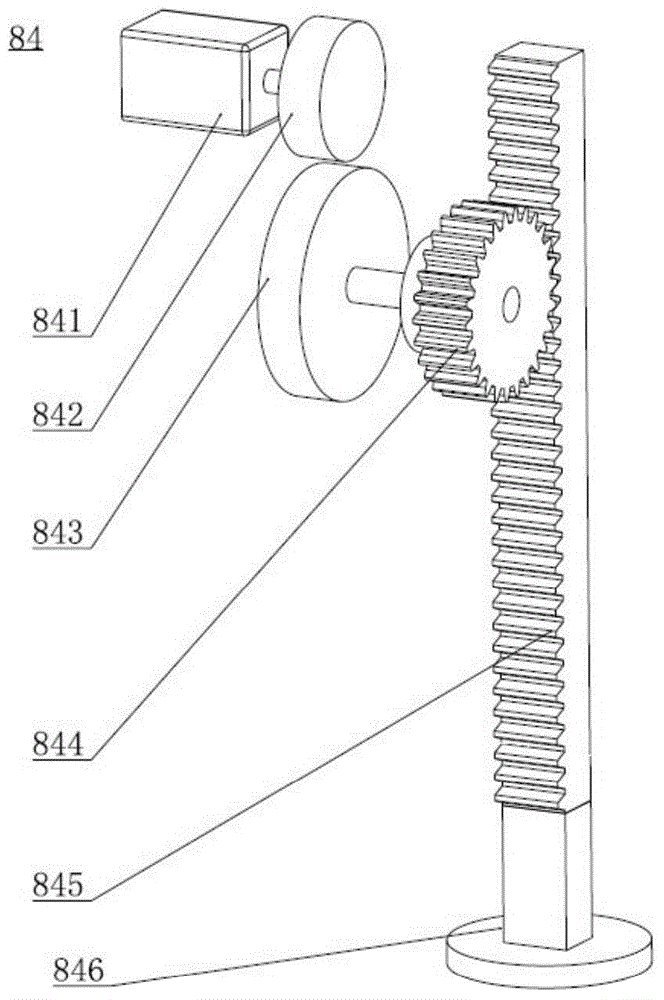

[0033] See also Figure 1 to Figure 8 .

[0034] According to one aspect of this embodiment, there is provided an assembly tooling for a C-shaped beam of an aircraft wing box, which includes a base platform and a top platform. Both the base platform and the top platform are rectangular structures with the same size and relative positions; The length direction of the base platform is the longitudinal direction, the width direction is the horizontal direction, and the direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com