An annealing process for stress relief after bright aluminum plating with ionic liquid

A technology of stress relief annealing and ionic liquid, which is applied in the field of annealing process to reduce the stress of bright aluminum coating, and achieves the effect of smooth and bright surface, low residual stress and satisfying performance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

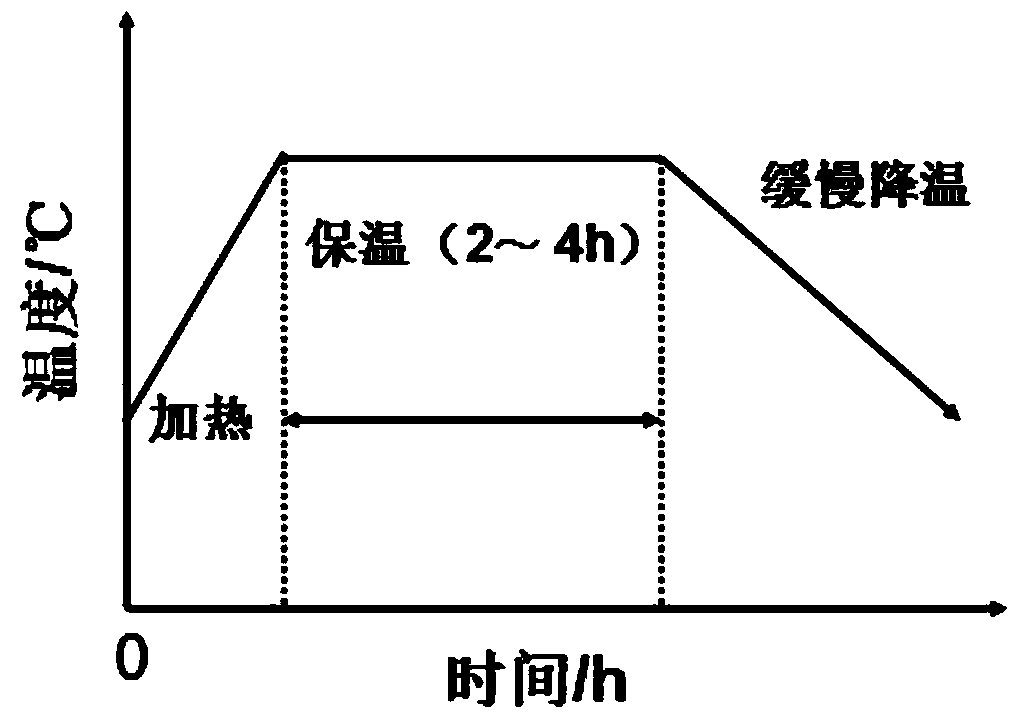

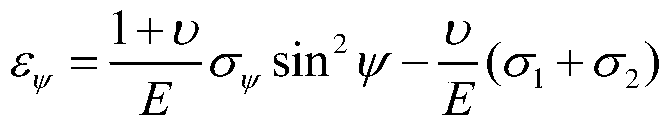

[0032] 1) According to the technical method of the patent (CN 103849911A), on the copper substrate, the bright aluminum coating was obtained by electrodeposition from the ionic liquid, and the measured residual stress of the coating was 843MPa;

[0033] 2) Place the plated parts to be annealed in a well-sealed vacuum annealing furnace. After the furnace is installed, pump the air until the vacuum degree is higher than 10 -5 After Pa, turn on the heating power, raise from room temperature to 200°C in 2 hours, keep the temperature for 2 hours, then cool down from 200°C to room temperature in 2 hours, then turn off the power directly. After stress relief annealing, the coating is bright and smooth, has good bonding force with the substrate, and the residual stress is reduced to 329MPa.

Embodiment 2

[0035] 1) According to the technical method of the patent (CN 103849911A), a bright aluminum coating was obtained by electrodeposition from an ionic liquid on a copper substrate, and the measured residual stress of the coating was 887MPa;

[0036] 2) Place the plated parts to be annealed in a well-sealed vacuum annealing furnace. After the furnace is installed, pump the air until the vacuum degree is higher than 10 -5 After Pa, turn on the heating power, rise from room temperature to 300°C in 2 hours, keep the temperature for 2 hours, then cool down from 300°C to room temperature in 4 hours, then turn off the power directly. After stress relief annealing, the coating is bright and smooth, has good bonding force with the substrate, and the residual stress is reduced to 272MPa.

Embodiment 3

[0038] 1) According to the technical method of the patent (CN 103849911A), on the copper substrate, the bright aluminum coating was obtained by electrodeposition from the ionic liquid, and the measured residual stress of the coating was 913MPa;

[0039] 2) Place the plated parts to be annealed in a well-sealed vacuum annealing furnace. After the furnace is installed, pump the air until the vacuum degree is higher than 10 -5After Pa, turn on the heating power, rise from room temperature to 300°C in 2 hours, keep the temperature for 3 hours, then cool down from 300°C to room temperature in 6 hours, then turn off the power directly. After stress relief annealing, the coating is bright and smooth, has good bonding force with the substrate, and the residual stress is reduced to 265MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| residual stress | aaaaa | aaaaa |

| residual stress | aaaaa | aaaaa |

| residual stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com