Compressible artificial graphite sheet

A technology of artificial graphite flakes and graphite, which is applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of affecting product performance, affecting service life, unfavorable heat dissipation in time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0018] A kind of compressible artificial graphite sheet provided by the invention, such as figure 1 As shown, it includes a graphite matrix 1, the graphite matrix 1 is synthetic graphite, and its thickness is 0.1-0.35mm. The graphite matrix 1 can be compressed according to the needs of different thicknesses.

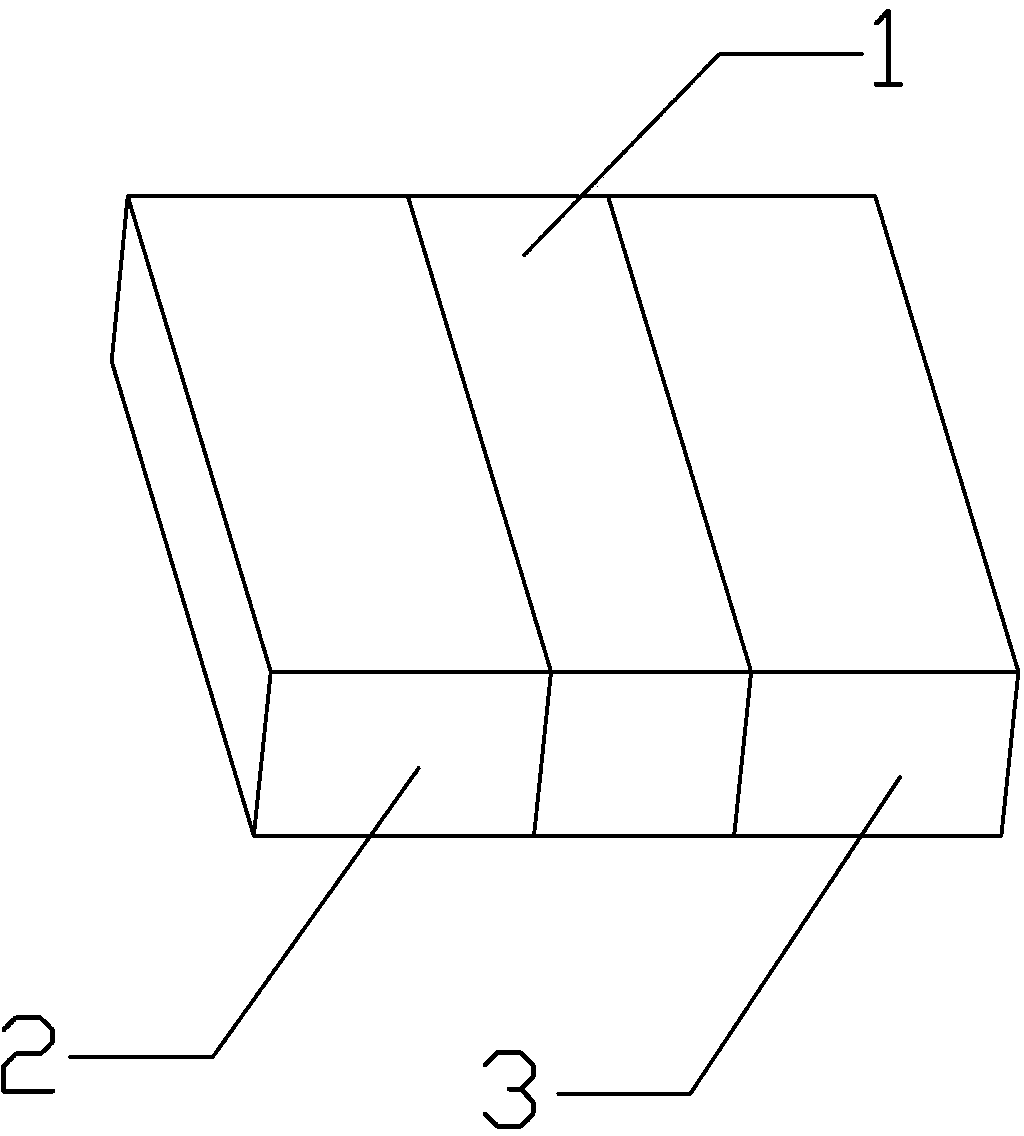

[0019] Such as figure 2 As stated above, the distance between the first working component 2 and the second working component 3 is less than 0.35mm, one side of the graphite substrate 1 is first attached to one side of the first working component 2, and then the second working component 3 is under pressure Compress the graphite matrix 1 to its predetermined position, and then the other side of the graphite matrix 1 is also attached to one side of the second working comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com