Fixture pre-clamping device

A pre-clamping and fixture technology, used in workpiece clamping devices, manufacturing tools, etc., can solve the problems of scratching the positioning pin holes of the workpiece, affecting the machining accuracy of the workpiece, and difficulty in clamping the workpiece, avoiding rollover, universal Strong, simple and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

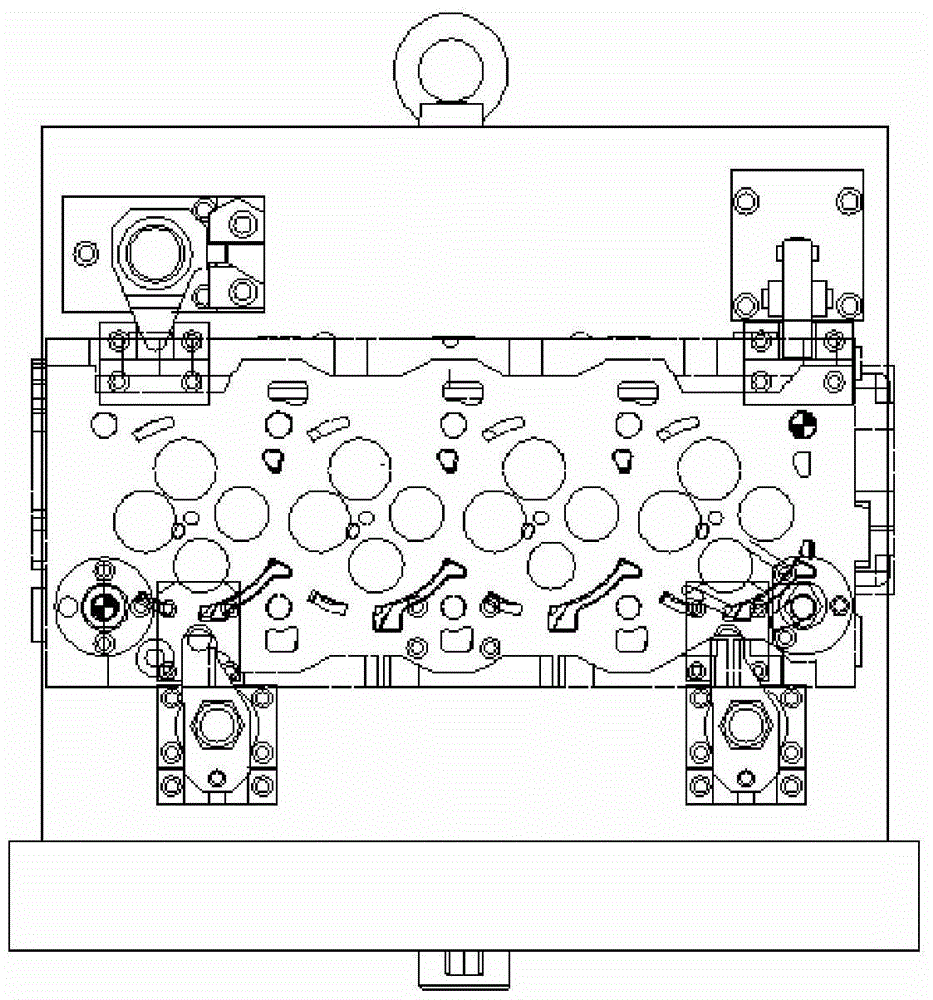

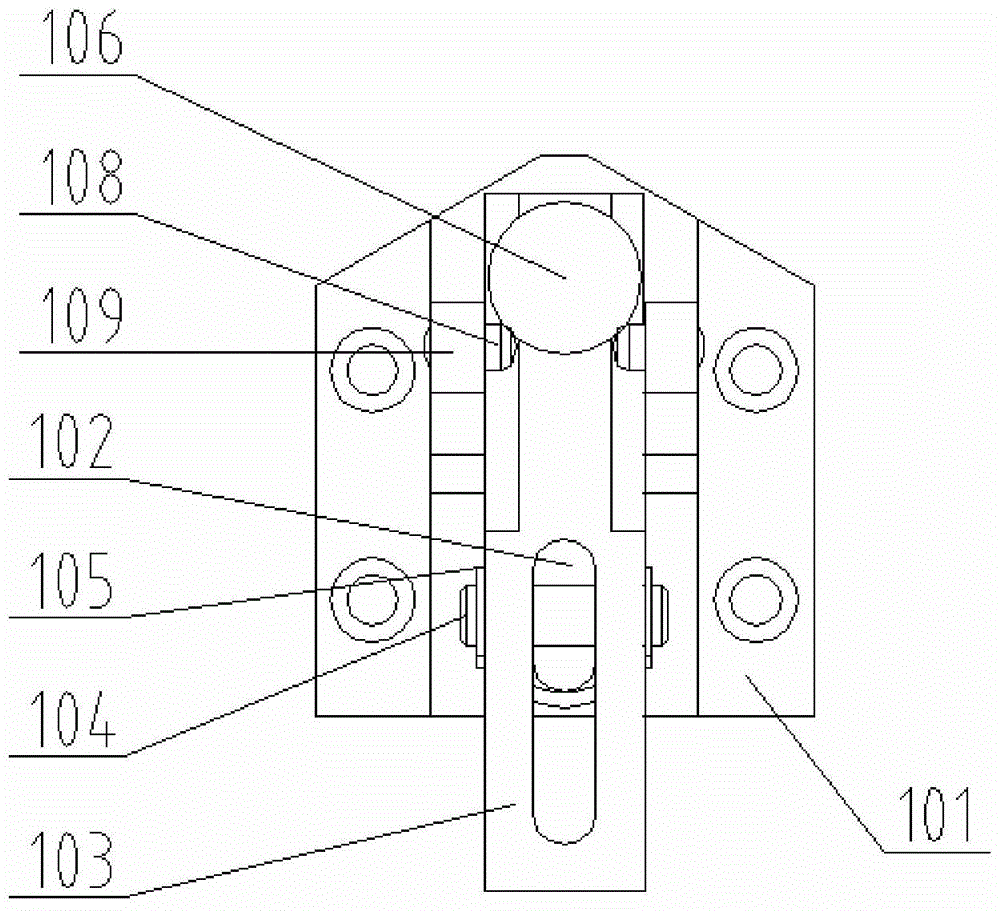

[0043] Such as figure 2 As shown, a clamp pre-clamping device 1 includes a base 101, a pressing plate 103, a guide assembly and a push rod assembly. The pressing plate 103 is slidably installed on the top surface of the base 101 , the guide assembly is arranged on the base 101 for guiding the sliding of the pressing plate 103 , and the ejector assembly is arranged in the base 101 for limiting the pressing plate 103 .

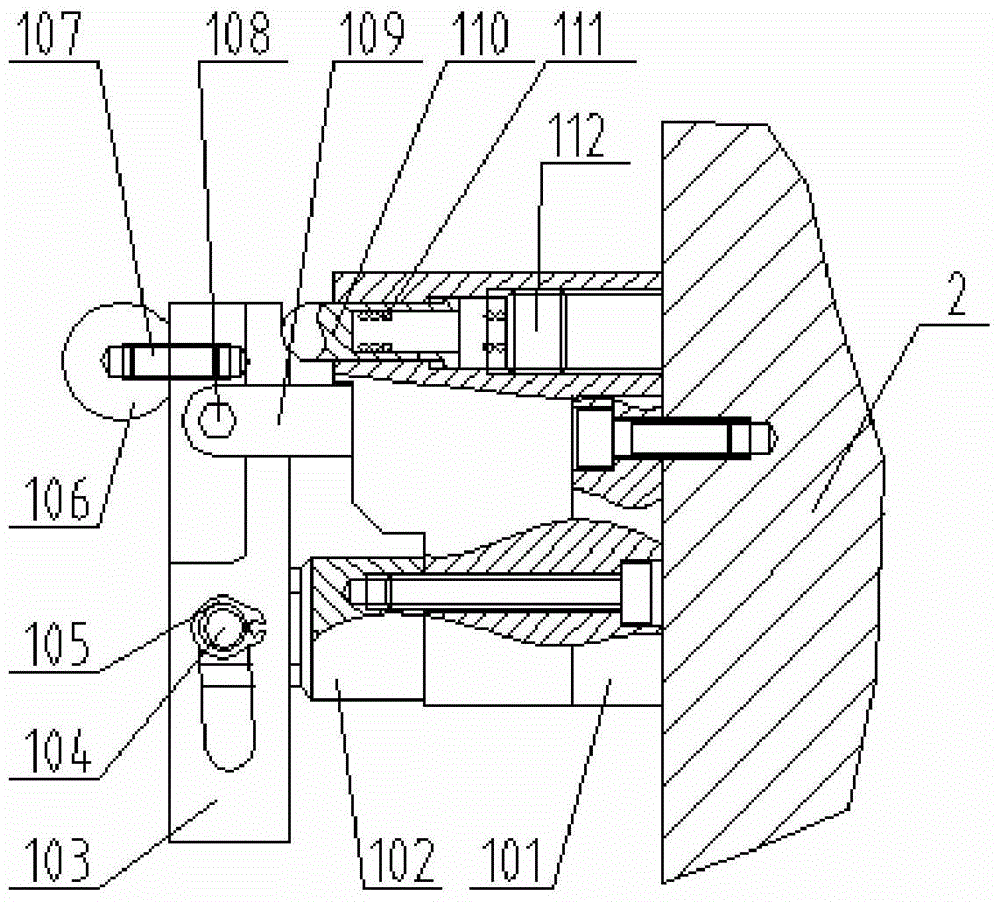

[0044] An example such as figure 2 with image 3 As shown, the guide assembly includes a U-shaped frame 109, such as Figure 10 As shown, the bottom plate of the U-shaped frame 109 is provided with a sixth mounting hole 1092, as Figure 5 As shown, the top surface of the base 101 is provided with a seventh installation hole 1014, and the bolt passes through the sixth installation hole 1092 and is screwed to the seventh insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com