A device for removing static electricity and particle impurities on the surface of electronic glass spacer paper

A glass spacer paper and particle impurity technology, which is applied in the direction of static electricity and electrical components, can solve the problems of spacer paper secondary pollution, glass surface scratches, particle impurities, etc., and achieve quality improvement, safety, and avoid accumulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

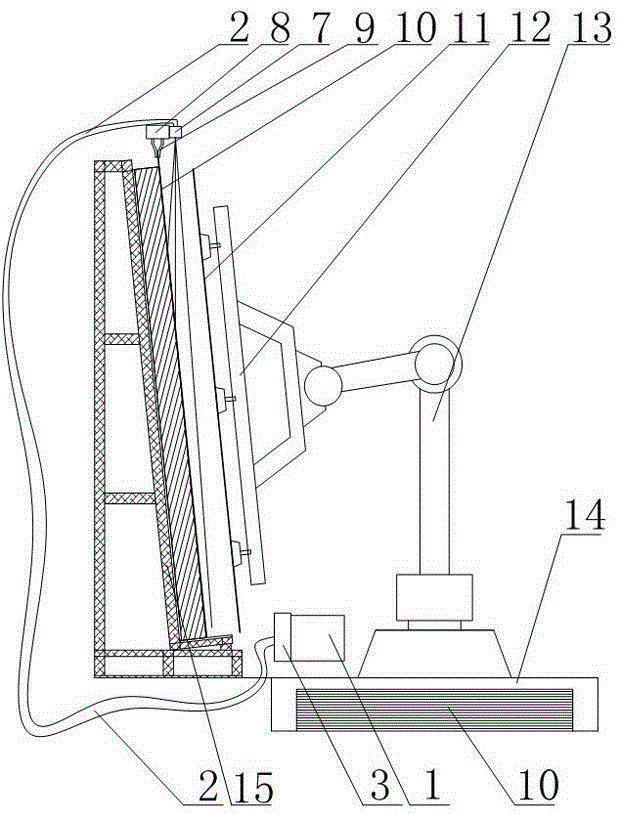

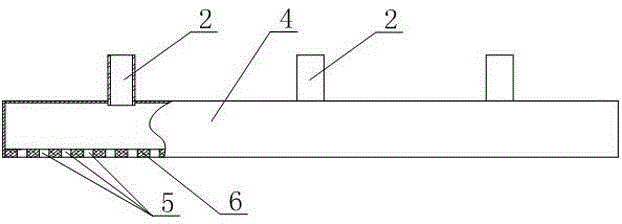

[0021] like Figures 1 to 2 As shown, a device for removing static electricity and particle impurities on the surface of the electronic glass spacer paper of the present invention includes a filter fan 1, and the clean air generated by the filter fan 1 first passes through the high-voltage discharge static eliminator 3, and the high-voltage discharge static eliminator 3 The output end is transported to the nozzle 7 through the hose 2. The nozzle 7 includes the wind collecting box 4. There is a spray plate 6 on the wind collecting box 4, and a plurality of spray holes 5 are evenly arranged on the spray plate 6. It enters the wind collecting box through the hose 2. 4 air is mixed to form a uniform air pressure, and then sprayed out from multiple nozzle holes 5 to form an air curtain; when in use, the spacer paper pick-up device 8 picks up the spacer paper 10 from the tray 14, and the spacer paper 10 is stacked in the tray 14 , the mechanical arm 12 of the robot 13 picks up the g...

Embodiment 2

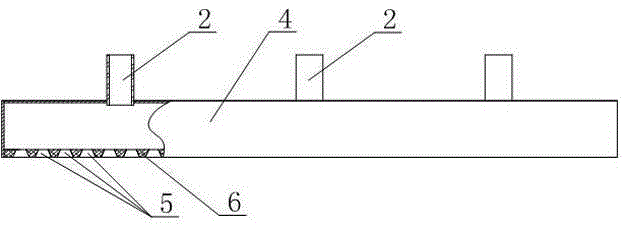

[0023] like figure 1 and image 3 As shown, the difference between this embodiment and Embodiment 1 is that the injection plate 6 has a certain thickness, and the aperture of the injection hole 5 gradually increases from the inside of the wind collection box 4 to the outside of the wind collection box 5, which is used to slow down the action of the medium on the baffle plate. Under the reflection and refraction, reduce the problem of uneven pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com