Battery separator and preparation method thereof, lithium ion battery, and communication equipment

A battery diaphragm and lithium-ion technology, applied in the battery field, can solve the problems of uneven distribution of perfluorosulfonic acid ion exchange resin, easy peeling of perfluorosulfonic acid ion exchange resin layer, and affecting the high-current discharge capacity of lithium-ion batteries. To achieve the effect of improving lithium ion conductivity, shortening the transfer path, and enhancing ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

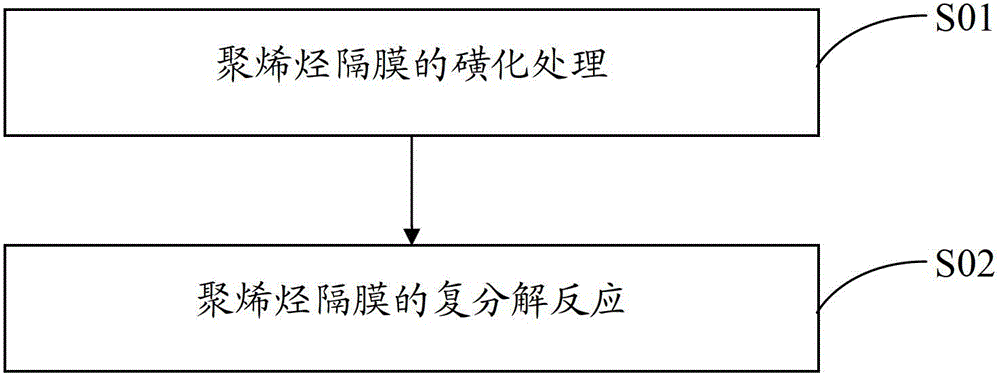

[0032] The example of the present invention also provides a preparation method of the above-mentioned battery diaphragm with simple process, strong conductivity and high liquid absorption rate. For the process flow of the preparation method of the battery separator, please refer to image 3 , including the following steps:

[0033] S01. Sulfonation treatment of polyolefin diaphragm: carry out sulfonation reaction between polyolefin diaphragm and oxidative acid solution dissolved in silver sulfate, wash and dry to obtain sulfonated polyolefin diaphragm;

[0034] S02. Metathesis reaction of polyolefin separator: immerse the polyolefin separator subjected to sulfonation treatment in step S01 into a solution containing lithium ions, perform metathesis reaction for 1 hour to 48 hours, and dry to obtain a battery separator.

[0035]Specifically, during the sulfonation reaction in the above step S01, under the action of an oxidizing acid, part of the hydrogen atoms in the polyolefin...

Embodiment 1

[0055] A battery diaphragm, a preparation method thereof and a lithium ion battery, the preparation method of the battery diaphragm comprises the following steps:

[0056] S11: Soak the PE film in a concentrated sulfuric acid solution with a concentration of 70% and a temperature of 40°C, wherein the concentrated sulfuric acid solution dissolves a silver sulfate catalyst with a concentration of 0.01mol / L, soak the PE film for 30 minutes, take it out, and wipe it with filter paper. Remove surface floating acid, soak in deionized water, rinse, wash away surface floating acid, vacuum dry at 80°C for 1 hour;

[0057] S12: Soak the PE separator after the sulfonation treatment in step S11 in a 0.5 mol / L lithium hydroxide solution at room temperature, take it out after 1 hour, and dry it under vacuum at 80° C. for 1 hour to obtain a battery separator.

[0058] The battery separator prepared in Example 1 is used to prepare a lithium-ion battery: the positive electrode, the battery sep...

Embodiment 2

[0060] A battery diaphragm, a preparation method thereof and a lithium ion battery, the preparation method of the battery diaphragm comprises the following steps:

[0061] S21: Soak the PE film in a chlorosulfonic acid solution with a concentration of 97% and a temperature of 25°C, wherein the chlorosulfonic acid solution dissolves a silver sulfate catalyst with a concentration of 0.01mol / L, soak the PE film for 30 minutes, take it out, and use Wipe off floating acid on the surface of the filter paper, soak in deionized water, rinse, and vacuum dry at 80°C for 1 hour;

[0062] S22: Soak the PE separator after the sulfonation treatment in step S21 in a 0.5 mol / L lithium carbonate solution at room temperature, take it out after 1 hour, and dry it under vacuum at 80° C. for 1 hour to obtain a battery separator.

[0063]The battery separator prepared in Example 2 is used to prepare a lithium-ion battery, and the specific preparation method is the same as that of the lithium-ion ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com