A method for measuring the sheath-core structure of carbon fiber pre-oxidized silk

A skin-core structure, pre-oxygen wire technology, which is used in the preparation of test samples and the use of measurement of secondary emissions for material analysis, etc., can solve the problems of large human factors, large interference of background pixel analysis, and high difficulty in operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

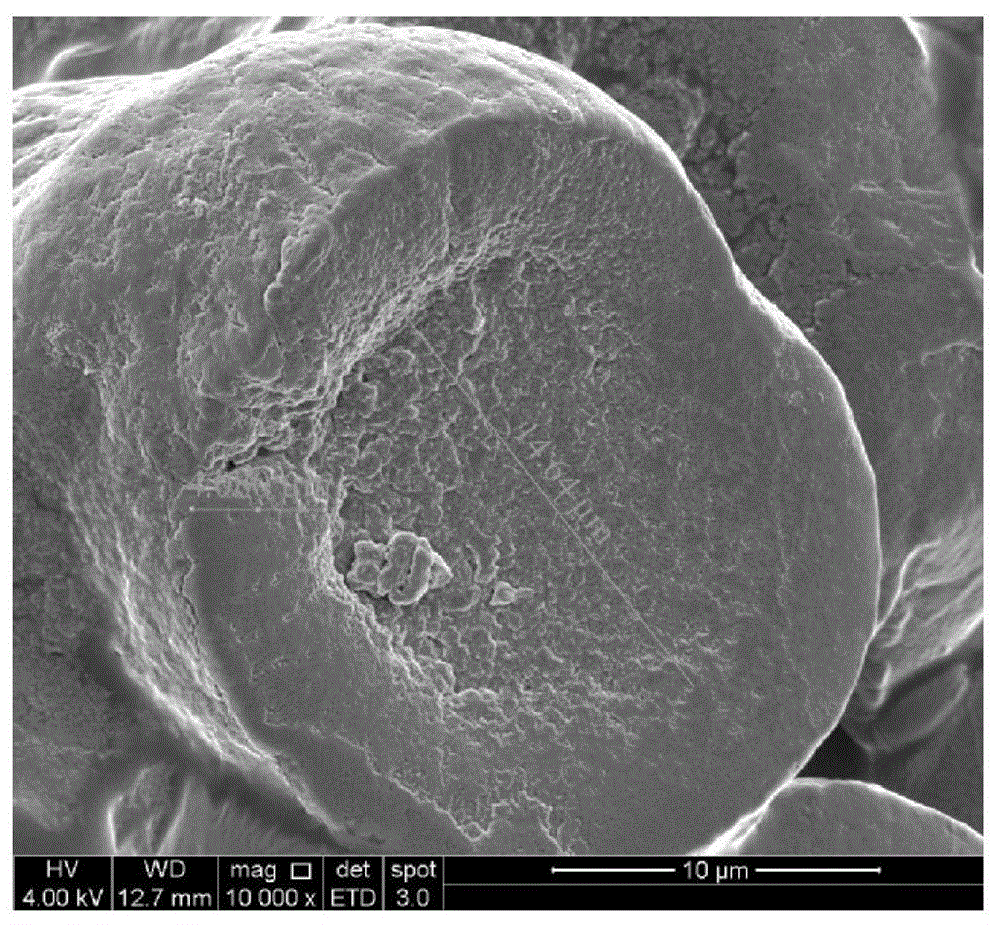

[0101] In this embodiment, the bulk density is 1.2343 / cm 3 The pre-oxidized wire was cured in the curing agent for 1 hour at room temperature, and then dipped and etched with 98% concentrated sulfuric acid for 10 minutes. The obtained SEM photos are as follows: figure 1 shown. The calculated core ratios are shown in Table 1.

Embodiment 2

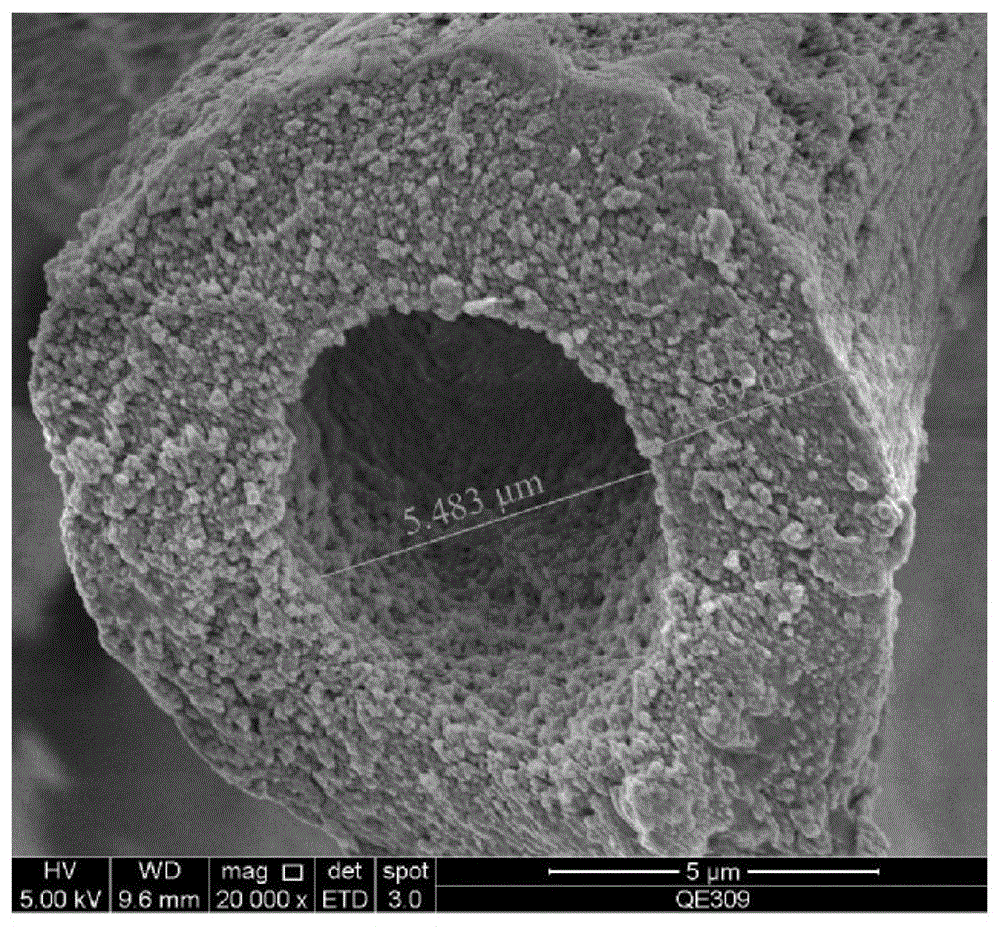

[0103] In this embodiment, the bulk density is 1.3240g / cm 3 The pre-oxidized wire was cured in the curing agent for 1 hour at room temperature, and then dipped and etched with 98% concentrated sulfuric acid for 3 minutes. The obtained SEM photos are as follows: figure 2 shown. The calculated core ratios are shown in Table 1.

Embodiment 3

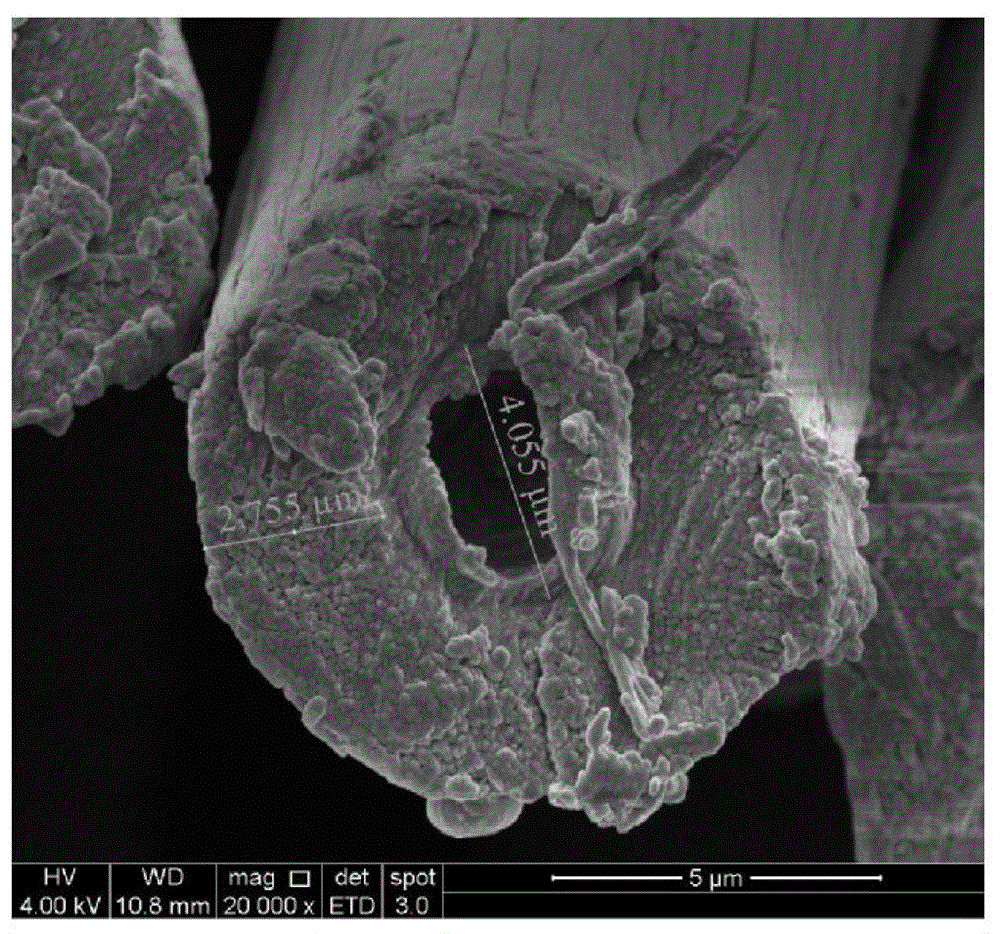

[0105] In this embodiment, the bulk density is 1.3240g / cm 3 The pre-oxidized wire was cured in the curing agent for 1 hour at room temperature, and then dipped and etched with 25% concentrated sulfuric acid for 48 hours. The obtained SEM photos are as follows: image 3 shown. The calculated core ratios are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com