Annular self-igniting groove for shale brick production and method for producing shale bricks

A technology of annular grooves and shale bricks, which is applied in the field of shale brick production equipment and its preparation of shale bricks, and preparation of building material equipment, to achieve effective utilization, improvement of product performance and quality, and significant technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Preparation of lightweight and environmentally friendly shale bricks

[0020] The specific steps of the processing method of light-weight and environment-friendly shale bricks are as follows:

[0021] (1) Optimize the preparation of brick materials and adjust the blank making process, optimize the shale roasting and vitrification conditions: classify and pulverize the raw materials, sieve through a 12-mesh sieve, and calculate according to the volume ratio of the powder: 65 parts of shale, cotton straw, sawdust, 15 parts of biomass waste such as sawdust, 20 parts of coal gangue, mix these crushed and sieved raw materials into a mixer, and add water to stir to form a semi-wet material. The water demand is 50-60% by weight, and it should not be too wet Or it is too dry. Generally, it is advisable to grab a handful of materials with your hands and squeeze them tightly to form a ball without water overflowing; send the semi-wet materials into a porous brick makin...

Embodiment 2

[0024] Embodiment 2: Optimizing the preparation of adobe materials and adjusting the adobe process

[0025] The method for preparing brick adobe materials and adjusting the adobe making process adopted in the present invention is: classify and pulverize the raw materials, sieve through a 12-mesh sieve, 65 cubic meters of shale, 15 cubic meters of biomass waste materials such as cotton stalks, sawdust, and wood chips, and coal gangue 20 cubic meters, mix these crushed and sieved raw materials into the mixer, and pour water and stir them into semi-wet materials. The water demand is about 50-55 cubic meters. It should not be too wet or too dry. Knead tightly to form a ball, but it is advisable to have no water overflow; send the semi-wet material into the porous brick making machine to make bricks, transport them to the drying yard for stacking and dry them naturally, and then transport the dried bricks to the brick roasting device.

Embodiment 3

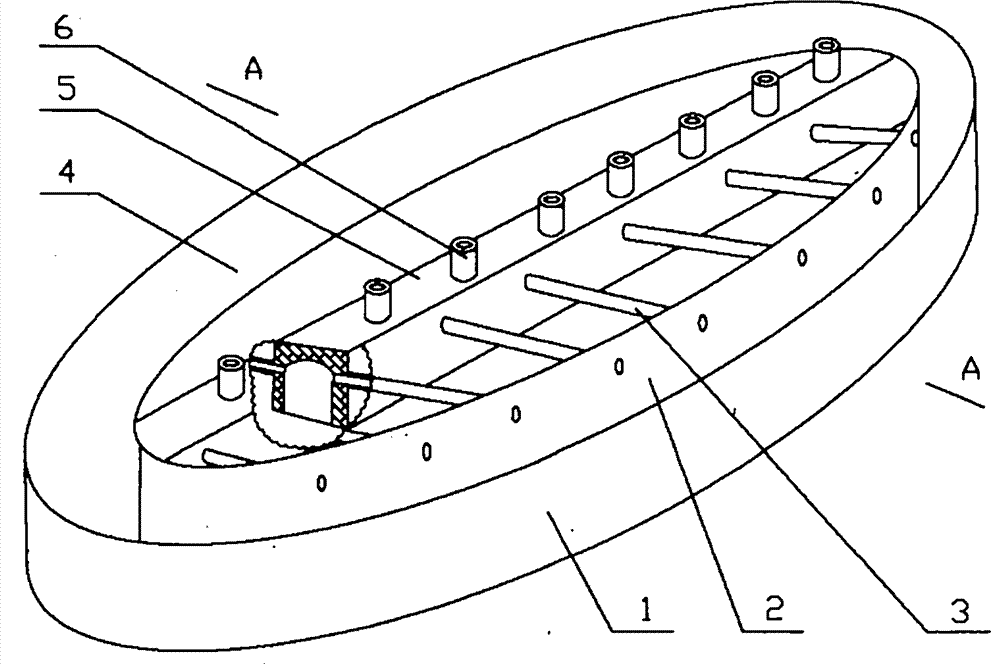

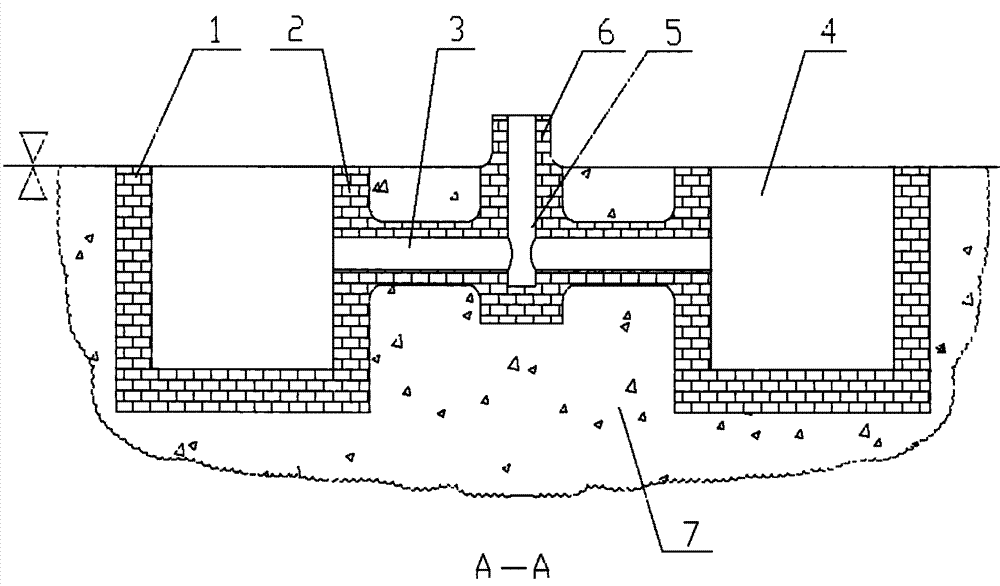

[0026] Embodiment three: the setting of the ring-shaped self-combustion tank without burning

[0027] In the present invention, the self-made annular self-combustion tank structure that replaces the traditional use of brick kilns and is free from firing is preferably used: the structure of the annular self-combustion tank body is in the shape of an elliptical underground annular tank body, and the annular tank (4) on both sides of the annular tank body is outside the annular tank Wall (1) and annular groove inner wall (2) are 2 meters high, and annular groove (4) bottom inner width is 2 meters, and annular groove (4) is long 30 meters, and annular groove (4) is built with bricks, and groove outer wall ( 1) The thickness of the wall is 0.3 meters, the top of the tank and the ground It is flat, and the outer circumference of the annular tank is open and flat, which is convenient for the transportation of bricks and finished bricks. The main flue (5) in the middle of the annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com