Hydraulic pressure expansion liner corrosion resistant alloy composite tube and manufacturing method thereof

A technology of corrosion-resistant alloy and manufacturing method, which is applied in the field of hydraulic expansion-lined corrosion-resistant alloy composite pipe fittings and its manufacture, can solve problems such as large process limitations, size restrictions, and unsuitability for promotion, and achieve easy promotion and solution construction desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

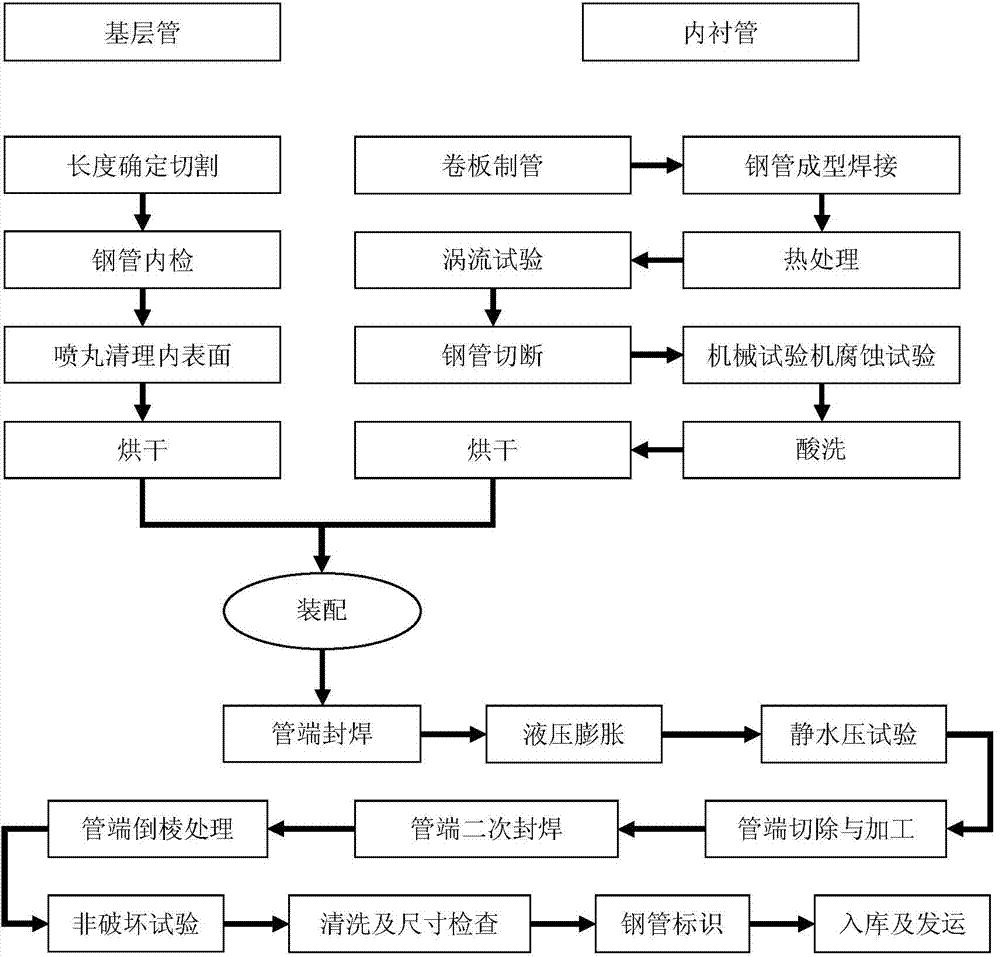

[0039] The invention according to figure 1 Process for the preparation of steel pipes.

[0040] (1) Outer tube preparation:

[0041] Cutting to length: Cut the base pipe to a certain length according to the product size specification requirements;

[0042] Inner surface inspection: Strictly check the quality of the inner surface of the base pipe to avoid defects that affect the bonding quality of the inner and outer pipes;

[0043] Inner surface treatment: Shot blasting is performed on the inner surface;

[0044] Purge and dry: purge and dry the inner surface for later use.

[0045] (2) Liner preparation

[0046] Pipe making: the stainless steel strip is rolled into a pipe blank, which is welded by TIG or plasma welding, the quality and shape of the weld are strictly controlled, and grinding is carried out if necessary;

[0047] Cutting to length: the qualified steel pipes are cut according to the requirements of the length;

[0048]Surface treatment: pickling treatment ...

Embodiment 1

[0057] steel number C Si mn P S Cr Ni Cu Mo Nb V Ti N X65 0.05 0.215 1.175 0.017 0.002 0.028 0.011 0.033 0.006 0.039 0.05 0.015 / 2205 0.024 0.572 1.63 0.009 0.002 22.8 5.76 / 3.12 / 0.024 / 0.13

[0058] YS(Rt0.5), MPa TS, MPa Elongation, % 460 555 43 465 565 40 460 565 42

Embodiment 2

[0060]

[0061]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com