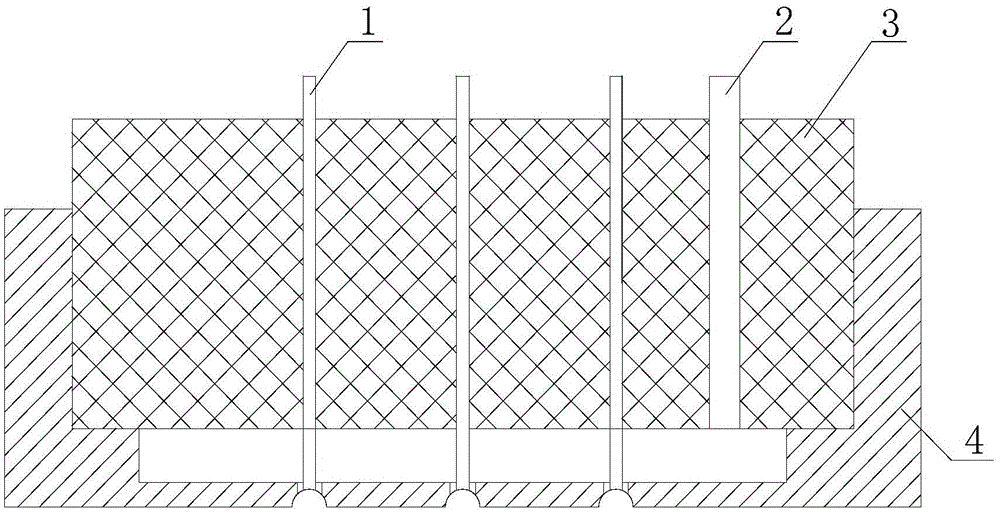

A flat pinhole coaxial electrospinning fiber composite spinneret and spinning method thereof

A technology of coaxial electrospinning and fiber compounding, which is applied in fiber processing, textile and papermaking, filament/thread forming, etc. Uniformity and other problems, to achieve the effect of easy detection, maintenance and cleaning, low equipment cost, and uniform electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

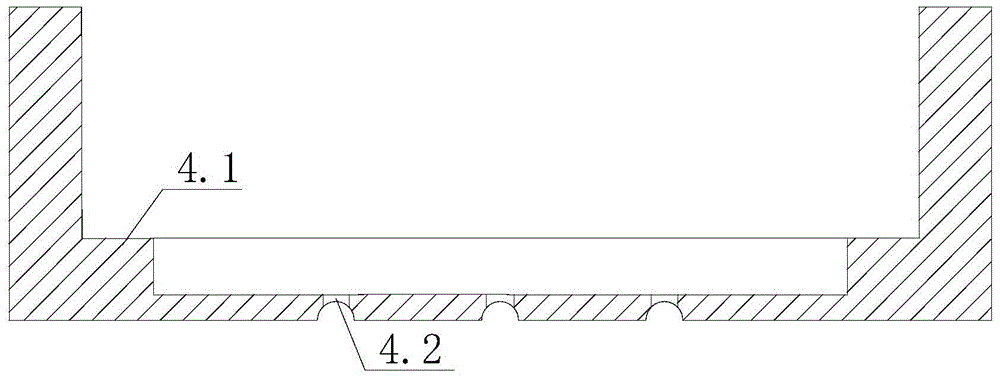

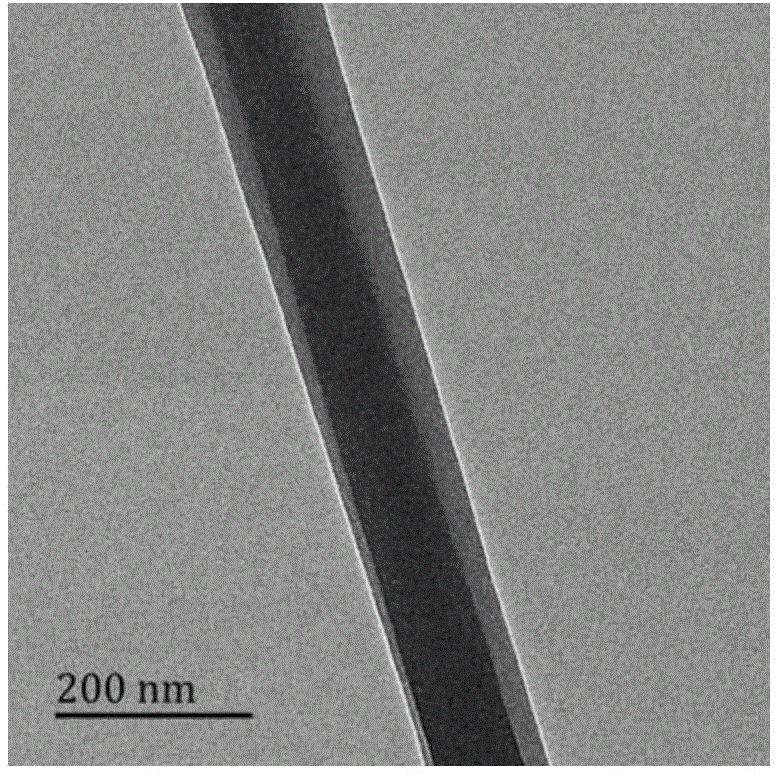

[0036] A kind of spinning method of flat pinhole coaxial electrospinning fiber composite spinneret, shell layer spinning liquid polyethylene oxide solution (a certain amount of relative molecular mass is 600,000 polyethylene oxide powder , dissolved in anhydrous ethanol and pure water mixed solvent, its volume ratio is 1:2, forming a homogeneous solution with a mass volume concentration of 2%) injected from the shell infusion channel (2) and filled with the solution cavity, and flow out from the through hole (4.2) to form the sheath of the composite fiber; the core layer spinning liquid polyvinyl alcohol solution (a certain amount of polyvinyl alcohol powder with a relative molecular mass of 146,000-186,000 , collagen is dissolved in pure water at a mass ratio of 1:1 to form a homogeneous solution with a mass volume concentration of 15%) injected from the core needle (1) to form the core layer of the composite fiber; the core shell layer The spinning solution merges in the gro...

Embodiment 2

[0038] A kind of spinning method of flat pinhole coaxial electrospinning fiber composite spinneret, shell layer spinning solution (with a certain amount of relative molecular mass being 30,000-70,000 polyvinyl alcohol powder, relative molecular mass 600,000 polyethylene oxide powder, according to the mass ratio of 10:1, dissolved in the mixed solvent of absolute ethanol and pure water, and its volume ratio is 1:2, forming a homogeneous mixture with a mass volume concentration of 10%. Solution) is injected from the shell layer infusion channel (2) and filled with the solution cavity all the time, and flows out from the through hole (4.2) to form the shell layer of the composite fiber; the core layer spinning solution polyethylene oxide solution (dissolving the dialyzed silk fibroin in pure water to form a homogeneous solution with a mass volume concentration of 50%) is injected from the core needle (1) to form the core layer of the composite fiber; the core layer and the shell l...

Embodiment 3

[0040] A kind of spinning method of flat pinhole coaxial electrospinning fiber composite spinneret, shell layer spinning liquid polystyrene solution (a certain amount of relative molecular mass is 350,000 polystyrene powder, dissolved in tetrahydrofuran and N,N-dimethylamide mixed solvent, the volume ratio of which is 1:4, forming a homogeneous solution with a mass volume concentration of 25%) injected from the shell infusion channel (2) and filled with the solution cavity, and flow out from the through hole (4.2) to form the sheath of composite fiber; 3 Polyurethane particles, dissolved in N,N-dimethylamide to form a homogeneous solution with a mass volume concentration of 8%) are injected from the core needle (1) to form the core layer of the composite fiber; the core layer and the shell layer are spun The silk liquid merges in the groove of the through hole to form composite droplets; a high-voltage direct current electric field is applied on the conductive electrode (3), a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com