Preparation method and reinforcement method of crispy powder ceramic culture relic reinforcement material

A technology of ceramic cultural relics and reinforcement materials, which is applied in the field of cultural relics protection to achieve good reinforcement protection and simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

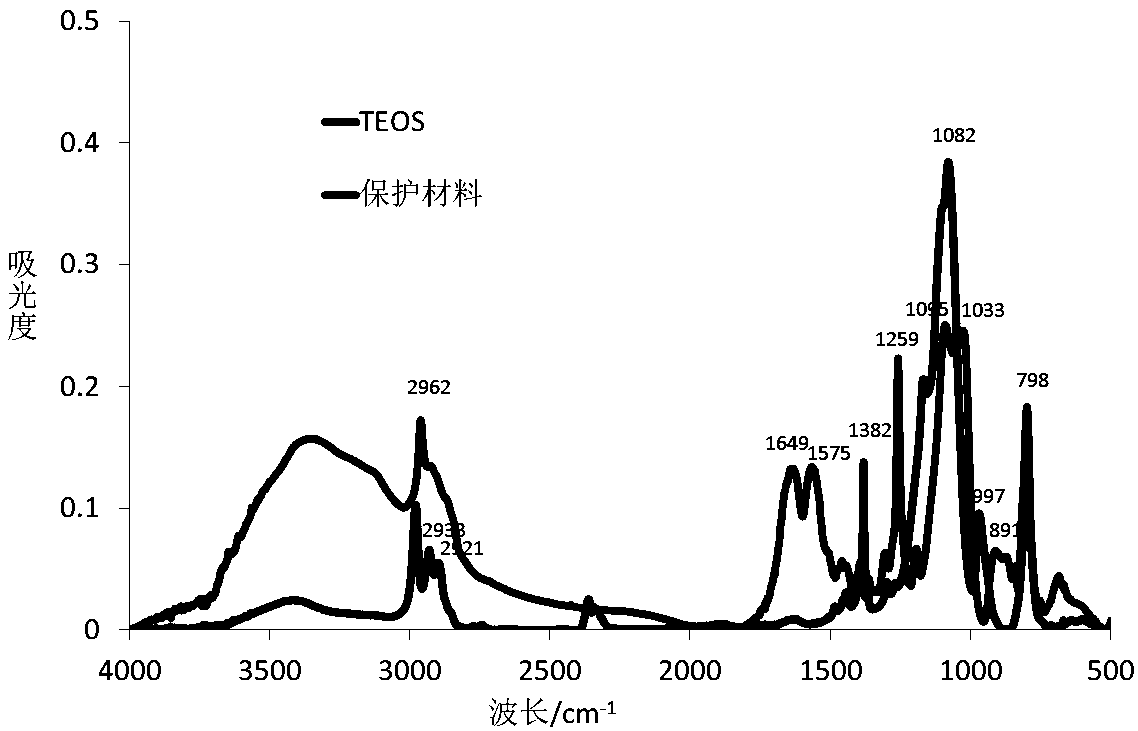

[0021] The preparation method of the crisp powder ceramic relics reinforcement material of the present invention comprises: mixing ethyl orthosilicate and hydroxyl-terminated polydimethylsiloxane, stirring for 12 to 24 hours; Continue to stir for more than 5 minutes under the action to prepare the crisp powder ceramic cultural relic reinforcement material.

[0022] The reinforcement method of the crisp powder ceramic cultural relics of the present invention comprises: slowly adding the reinforcement material prepared by the above preparation method on the crisp powder ceramic cultural relics covered with adsorption materials until the adsorption materials are in a saturated state; Store in the box until the reinforcing material is completely cured.

[0023] In combination with the above preparation method and reinforcement method, more specifically, as an example, the present invention may include the following steps.

[0024] (1) Add hydroxyl-terminated polydimethylsiloxane ...

Embodiment 1

[0033] The main steps of the preparation of a reinforcement and protection material for crunchy powder pottery cultural relics caused by reinforcement of soluble salts such as sodium chloride and calcium chloride are as follows:

[0034]Add 5ml of hydroxyl-terminated polydimethylsiloxane with a molecular weight of 700, a hydroxyl group content of 4-6%, and a viscosity of 32cst to 50ml of tetraethyl orthosilicate, control the temperature of the heating magnetic stirrer at 25°C, and the speed of 400rpm, and add magnetic force to the liquid After stirring with a stirring bar for 24 hours, add 0.5ml of catalyst dibutyltin dilaurate and stir for 5 minutes, and synthesize crisp powder ceramic cultural relics reinforcement and protection material.

[0035] The protection steps for consolidating the fragments of crispy powder pottery cultural relics unearthed from the Dianzi Qin Tomb in Longxian County, Shaanxi Province are as follows:

[0036] Use the pulp wrapping method and multipl...

Embodiment 2

[0039] The reinforcement and protection material preparation of crispy powder pottery cultural relics is as in Example 1;

[0040] The protection steps of the reinforced crisp powder simulation sample are as follows:

[0041] Take Shaanxi Qinling clay and sieve it with 100 meshes, then fire it in a muffle furnace at 700°C to make ceramic crisp powder particles, weigh 2.00g of pottery powder, use a sample box with a diameter of 2.5cm as a mold, and the depth of the pottery powder sample is 6mm , 5ml of reinforcement material, slowly drip the protection material with the needle dripping method, all the materials are infiltrated into the ceramic powder sample, and the reinforced sample is sealed and placed in a constant temperature and humidity box with a temperature of 25°C and a relative humidity of 50% for 2 weeks. ;

[0042] The test results of the crispy powder simulation sample after protection are as follows: ①The color change value of the surface before and after reinfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com