Three-dimensional sheet TiO2 material and preparation method and application thereof

A three-dimensional, sheet-like structure technology, applied in chemical instruments and methods, titanium oxide/hydroxide, physical/chemical process catalysts, etc., can solve problems such as easy danger, severe hydrolysis, and difficulty in obtaining three-dimensional complex structures, and achieve The effect of novel shape, simple process and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Put 0.1g of metallic Ti powder into 150mL of a mixed solution of hydrogen peroxide and nitric acid, wherein the concentration of hydrogen peroxide is 9M, and the concentration of nitric acid is 0.1M; then condense and reflux in an oil bath at 80°C for 2 hours to obtain an orange color solution;

[0033] (2) Measure 18mL of the orange-yellow solution prepared in step (1), mix it with 42mL of 10M NaOH solution in a PTFE liner with a volume of 100mL and stir for 25min, then hydrothermally react at 180°C for 5h;

[0034] (3) After the reaction, the precipitate was separated by centrifugation, washed with 0.1M nitric acid and deionized water until the pH value was 7; then dried in an oven at 80°C to obtain a three-dimensional flaky TiO 2 Material.

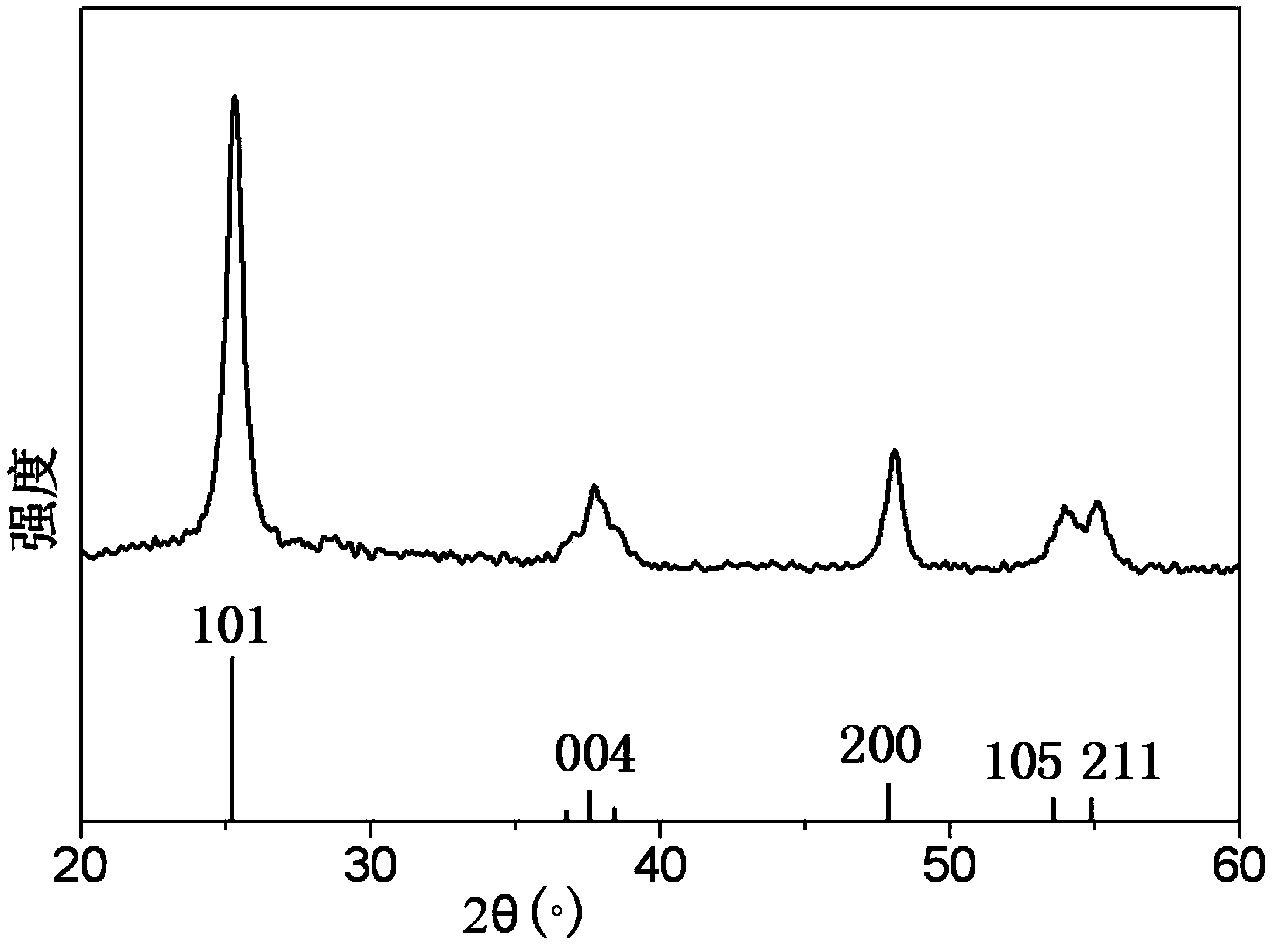

[0035] figure 1 , figure 2 The three-dimensional flaky TiO that this embodiment makes 2 The scanning electron microscope images of the material at different magnifications. It can be seen from the figure that the three-d...

Embodiment 2

[0039] (1) Put 0.1g of metallic Ti powder into 150mL of a mixed solution of hydrogen peroxide and nitric acid, wherein the concentration of hydrogen peroxide is 9M, and the concentration of nitric acid is 0.1M; then condense and reflux in an oil bath at 80°C for 3 hours to obtain an orange color solution;

[0040] (2) Measure 9mL of the orange-yellow solution prepared in step (1), mix it with 21mL of 10M NaOH solution in a PTFE liner with a volume of 100ml and stir for 10min, and then carry out at a temperature of 200°C. Hydrothermal reaction, time is 5h;

[0041] (3) After the reaction is completed, the product is centrifuged and washed with 0.1M nitric acid and deionized water until the pH value of the product obtained in step (2) is 7; then dried in an oven at 80°C to obtain a three-dimensional sheet TiO 2 Material.

[0042] Figure 5 , Figure 6 The three-dimensional flaky TiO that this embodiment makes 2 The scanning electron microscope images of the material at diffe...

Embodiment 3

[0045] (1) Put 0.05g of metallic Ti powder into 100mL of a mixed solution of hydrogen peroxide and nitric acid, wherein the concentration of hydrogen peroxide is 9.5M, and the concentration of nitric acid is 0.2M; then condense and reflux in an oil bath at 90°C for 2 hours to obtain orange yellow solution;

[0046] (2) Measure 18 mL of the orange solution prepared in step (1), mix it with 22 mL of 9M NaOH solution in a PTFE liner with a volume of 100 mL, and stir for 20 min, then hydrothermally react at 190°C for 6 h;

[0047] (3) After the reaction, the precipitate was separated by centrifugation, washed with 0.1M nitric acid and deionized water until the pH value was 7; then dried in an oven at 80°C to obtain a three-dimensional flaky TiO 2 Material.

[0048] Figure 8 The three-dimensional flaky TiO that this embodiment makes 2 The scanning electron microscope picture of the material shows that the side length of the sheet-like structure of the sheet-like material is 7 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com