Method for preparing printed electronic resistance welding material based on household piezoelectric inkjet printing technology

An inkjet printing and piezoelectric technology, which is applied in the field of preparing printed electronic solder resist materials based on piezoelectric household inkjet printing technology, can solve the problems of restricting the development of the printed electronics industry, expensive printers, and expensive nozzles. , to achieve the effect of saving solder mask ink materials, increasing reliability and yield, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

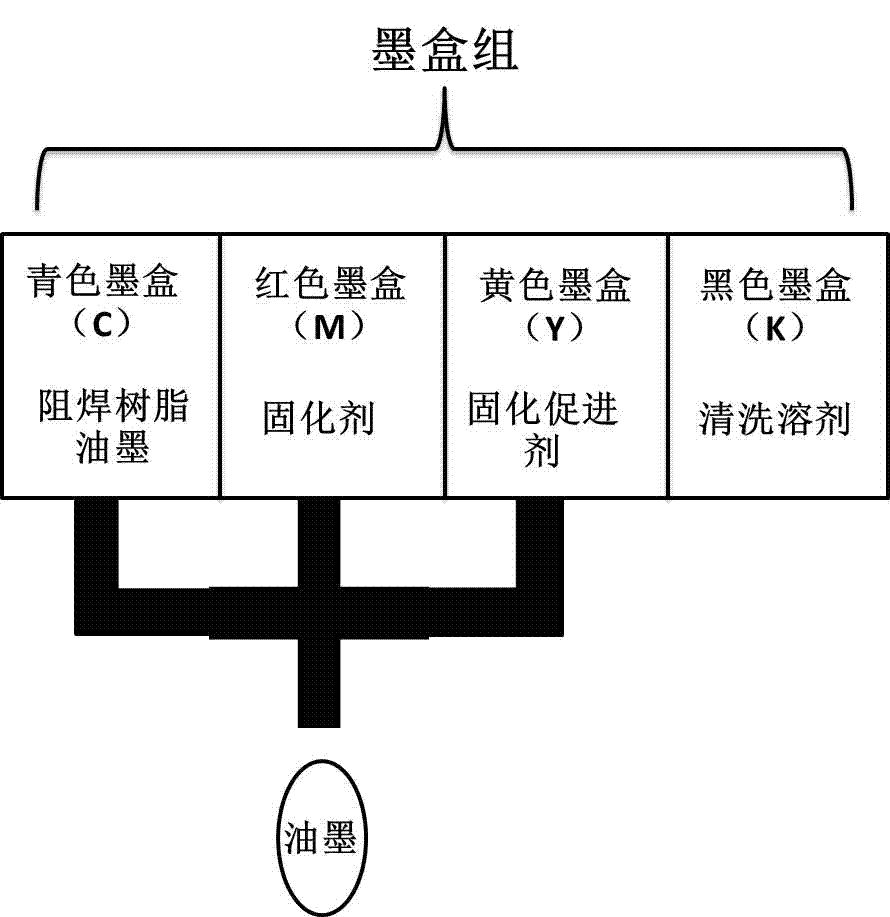

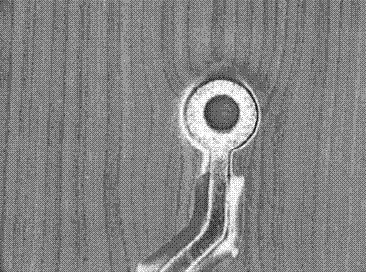

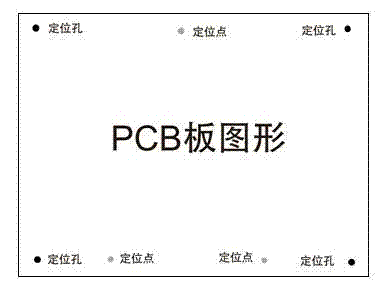

[0031] Using Epson Me1+ piezoelectric inkjet printer, UV curing solder resist ink formula as figure 1 As shown (70% solder resist resin (PEG modified E51 epoxy resin), 25% curing agent (Dow Chemical, UVI-6976), 5% curing accelerator (Dow Corning, Z-6040)), respectively, the resin ink Put the cyan ink cartridge (C), the curing agent into the magenta ink cartridge (M), the curing accelerator into the yellow ink cartridge (Y), and the cleaning agent into the black ink cartridge (K). First, adjust the printer to be all black and clean the bumper 3 times, then put the flex PCB to be printed (the substrate is PI) into the carton, and print the positioning holes and positioning points. Prepare the PCB circuit solder mask pattern to be printed, adjust the ink output according to the CMYK color coordinates to 70% for cyan (C), 25% for magenta (M), 5% for yellow (Y), and 0 for black (K) %, the three inks are mixed at the meeting point of the printer to obtain the required solder resist...

Embodiment 2

[0033] Self-modified Epson R230 piezoelectric inkjet printer was adopted, and the original paper feeding system was changed to a belt-driven linkage paper feeding system (refer to the universal printer for modification). Heat curing solder resist ink formula (30% solder resist resin component 1 (PEG modified E51 epoxy resin), 35% solder resist resin component 2 (hyperbranched polyester Boltorn H20 modified acrylic resin), 10% curing agent Component 1 (triethylenetetramine), 10% curing agent component 2 (triethylamine), 5% curing accelerator (DMP-30 20wt% acetone solution)), respectively put solder resist ink resin component 1 into Cyan ink cartridge, solder resist ink resin component 2 into light cyan ink cartridge, curing agent component 1 into magenta ink cartridge, curing agent component 2 into light magenta ink cartridge, curing accelerator into yellow ink cartridge, cleaning solvent into Insert the black ink cartridge. First, adjust the printer to all black and clean the...

Embodiment 3

[0035]Self-modified Epson R230 piezoelectric inkjet printer and LED linkage UV light source are added. UV curable solder resist ink formula (30% solder resist resin component 1 (PEG modified E51 epoxy resin), 35% solder resist resin component 2 (hyperbranched polyester Boltorn H20 modified acrylic resin), 15% curing agent Component 1 (Dow Chemical, UVI-6976), 5% Curing Agent Component 2 (Dow Chemical, UVI-6992), 5% Curing Accelerator (Dow Corning, Z-6040)), the solder resist ink resin Component 1 is loaded into the cyan ink cartridge, solder resist ink resin component 2 is loaded into the light cyan ink cartridge, curing agent component 1 is loaded into the magenta ink cartridge, curing agent component 2 is loaded into the light magenta ink cartridge, and curing accelerator is loaded into the yellow ink cartridge Cartridge, cleaning solvent into the black cartridge. First, adjust the printer to all black and clean the head 3 times, then put the hard board PCB to be printed (t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com