Single hand rope installation mechanism and installation method

An installation mechanism and a single root technology, applied in packaging, transportation and packaging, container manufacturing machinery, etc., can solve the problems of easy damage to the bag body, inconvenient operation, hand-carrying knots and poor length consistency, and achieve a good degree of automation. Improved convenience and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

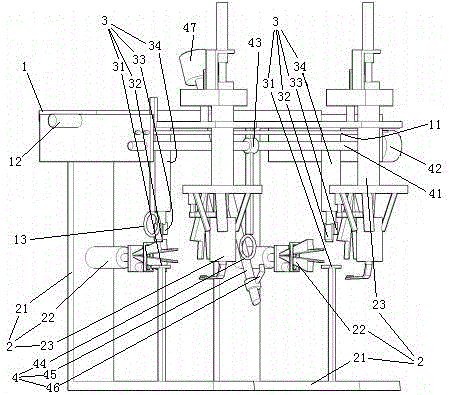

[0040] Embodiment one, see figure 1 , a single handle rope installation mechanism, including a frame 1. The frame 1 is provided with two rope-threading and knotting mechanisms 2, two cutting knives 3 and a hand rope fixed-length feeding mechanism 4.

[0041] Two threading and knotting mechanisms 2 are distributed on the frame 1 along the left and right directions. Two threading and knotting mechanisms 2 are located between two cutting knives 3 . The threading and knotting mechanism 2 includes a mounting base 21 and a rope-threading manipulator 22 and a knotting structure 23 arranged on the mounting base 21 .

[0042] The cutting knife 3 includes an anvil 31 disposed on the mounting base 21 , a blade 32 and a pressing block 33 located above the anvil 31 . The blade 32 and the pressing block 33 are installed on the mounting base 21 through the cutting cylinder 34 .

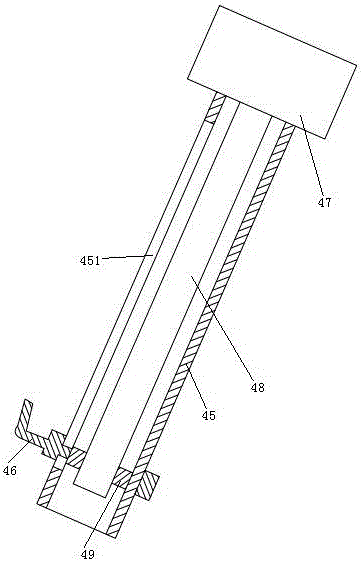

[0043] The hand rope fixed-length feeding mechanism 4 includes a rope pick ring 44, a guide rod 45 and a rope...

Embodiment 2

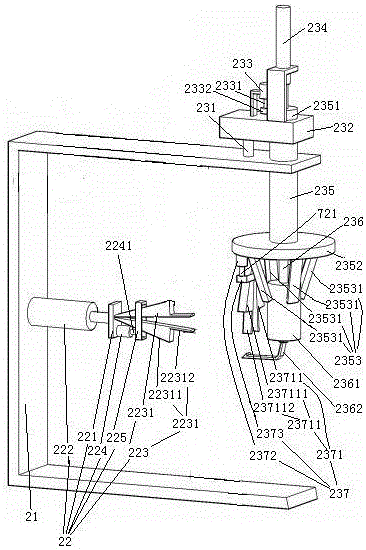

[0069] Embodiment two, the difference with embodiment one is: see Figure 6 , the rope-threading clips 2231 are hinged together through the hinge shaft 2232 . The outer surface of the rope clip closing control section 22311 is a tapered surface. An expansion spring 2233 is arranged between the pair of rope-threading clips 2231 . The free end face 223121 of chuck is spherical. The pair of stringing clips 2231 are kept apart by expanding the spring 2233 . The structural form of the rope-winding clip that constitutes the rope-winding manipulator is the same as the structural form of the rope-threading clip.

[0070] see Figure 7 The rope withdrawal structure 2353 includes a rope withdrawal ring 23532 sleeved on the rope winding section 2361 and a connecting rod 23533 for suspending the rope withdrawal ring 23532 on the turntable 2352 . The lifting rod 236 is provided with an adsorption channel 2363 extending along the vertical direction. The inlet 23631 of the adsorption c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com