Method for improving grinding efficiency of shear blade

A grinding and sharpening technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, abrasive surface adjustment devices, etc. The effect of reducing auxiliary installation time, reducing depreciation speed and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] figure 1 It is a grinding wheel sheet that has not been used in the present invention.

[0015] figure 2 It is the grinding wheel sheet used in the present invention.

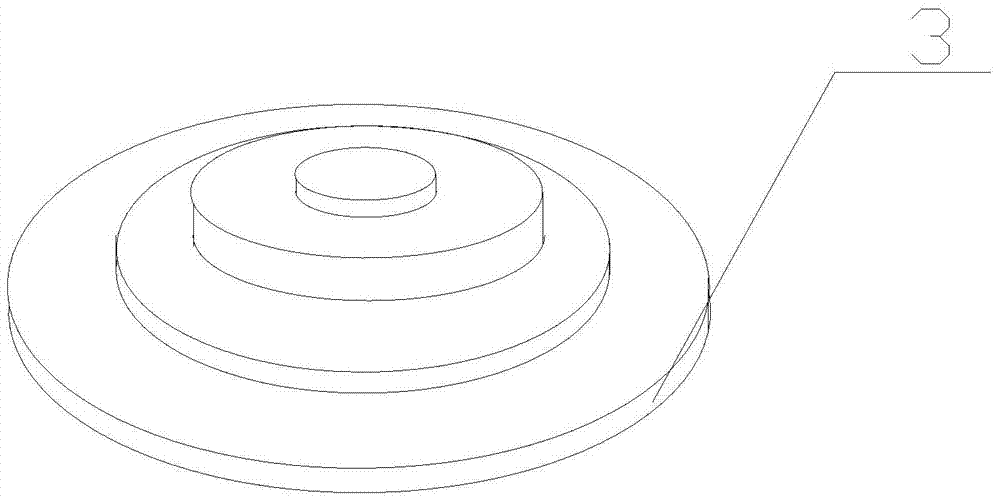

[0016] image 3 It is a grinding wheel sheet discarded after use in the present invention.

[0017] 1-thickness of unused grinding wheel 2-thickness of grinding wheel in use 3-thickness of scrapped grinding wheel

[0018] Below in conjunction with accompanying drawing, the steps of the present invention are further described:

[0019] A method for improving the grinding efficiency of shear blades, comprising the following steps:

[0020] 1) Use group grinding for the shearing edge surfaces with similar curves;

[0021] 2) Increase the use space of the grinding wheel and increase the thickness of the grinding wheel so that the thickness is between 80mm and 100mm;

[0022] 3) Adjust the grinding wheel dresser. When opening a second new grinding surface on the same grinding wheel, adjust the program...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com