Production additive capable of increasing and improving yield and quality of calcium carbonate powder and use method of production additive

A technology of calcium carbonate stone powder and calcium carbonate powder, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problem of high energy consumption, achieve good compatibility, reduce depreciation speed, and save labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

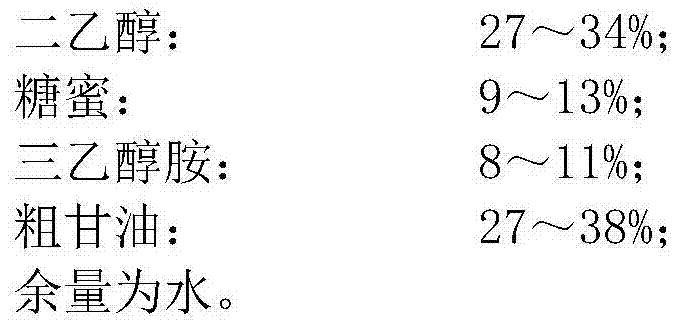

[0037] The additives of this example include the following substances in terms of mass fraction:

[0038]

[0039] When this additive is used for grinding calcium carbonate stone powder, the dosage is 1.3 grams of this additive per kilogram of calcium carbonate stone powder.

[0040] After testing, with 325 mesh, the sieving and filtration of calcium carbonate stone powder reaches 86%.

example 2

[0042] This additive includes the following substances in terms of mass fraction:

[0043]

[0044] When the calcium carbonate stone powder is finely ground, the dosage is 1.3 grams of this additive per kilogram of calcium carbonate stone powder.

[0045] After testing, with 325 mesh, the sieving and filtration of calcium carbonate stone powder reaches 89%.

example 3

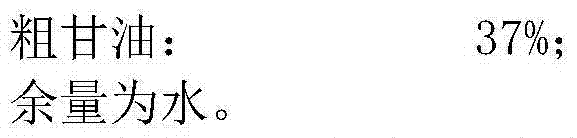

[0047] This additive includes the following substances in terms of mass fraction:

[0048]

[0049] When this additive is used for grinding calcium carbonate stone powder, the dosage is 1 gram of this additive per kilogram of calcium carbonate stone powder.

[0050] After testing, with 325 mesh, the sieving and filtration of calcium carbonate stone powder reaches 83%.

[0051] The stone powders of Examples 1-3 are used in the FGD system. After testing, the conversion fraction of calcium carbonate stone powder is generally increased by about 17%. It shows that after adopting this additive, the reactivity of calcium carbonate stone powder is greatly improved than that of calcium carbonate stone powder without this additive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com