Multifunctional pipe welding fixture

A pipe body and steel pipe technology, which is applied in the field of pipeline welding multifunctional tooling, can solve the problems of long welding time, poor welding quality, complicated process, etc., and achieve the effect of improving work efficiency and quality, and good welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

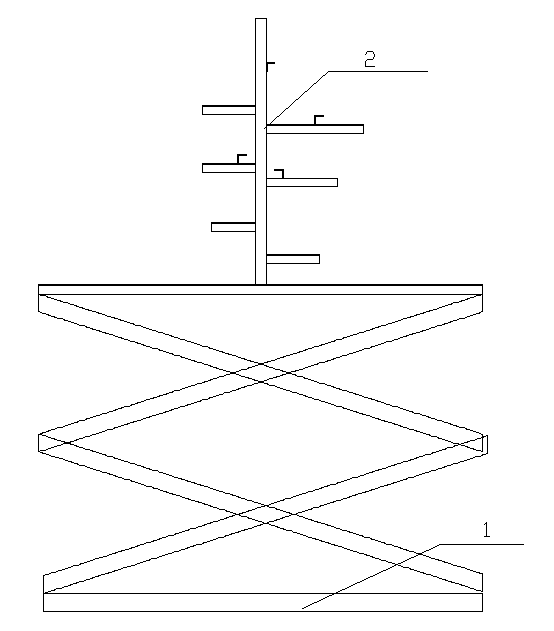

[0009] Such as figure 1 It is a schematic diagram of the structure of the present invention. A multifunctional tooling for pipe welding includes a mobile lifting platform 1 and a welding bracket 2. The welding bracket 2 is installed on the mobile lifting platform 1. When the weldment needs to be welded, the weldment can be fixed on the fixture bracket 2 according to the shape of the weldment on the tooling, so that each welding joint is in a flat fillet position, which is beneficial to ensure the welding quality; the welding bracket 2 can also be Rotate at any position on the mobile lifting platform 1, according to the shape of the pipeline, rotate the corresponding angle, so that the workpiece is always in the position where welding is the easiest to ensure welding quality, improve work efficiency; welding can also be based on the height of the welder , The height of the weldment position, and the height of the mobile lifting platform 1 for welding habits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com