Ear stud welding machine

A welding machine and ear stud technology, which is applied in welding equipment, earrings, electric heating devices, etc., can solve the problems of low production efficiency, long training period for workers, high labor cost, etc., and achieve high production efficiency, good welding quality and automation. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing:

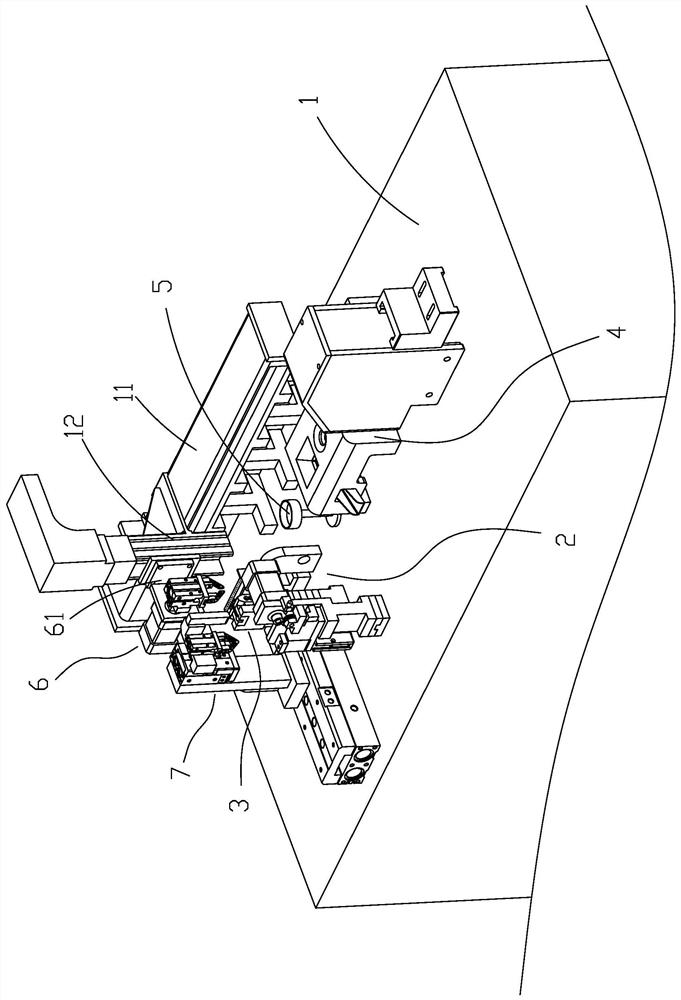

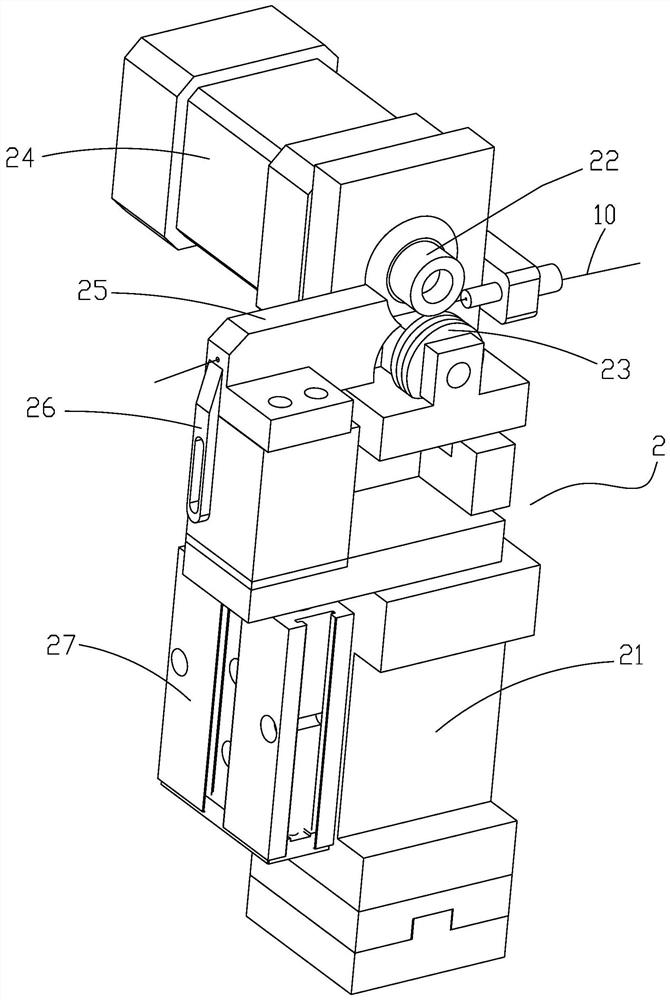

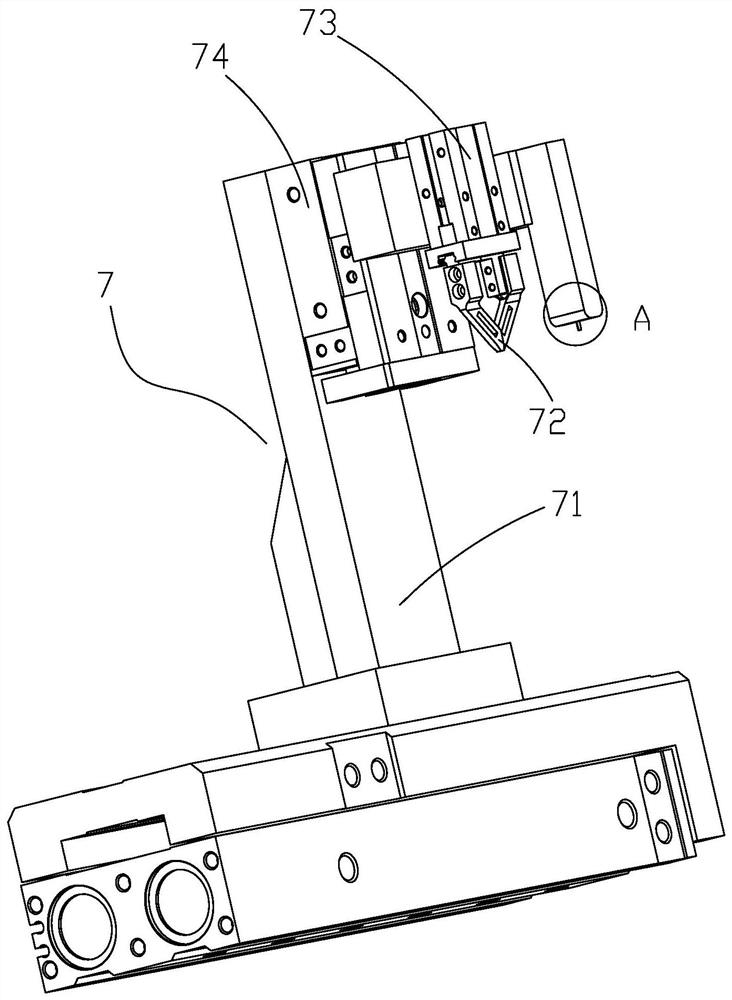

[0036] Such as figure 1 , figure 2 , Figure 5 , Figure 12 , Figure 13 and Figure 14 As shown, an ear stud welding machine includes a frame 1, and the frame 1 is provided with a welding wire distributing device 2 capable of distributing welding wire 10, and a welding wire winding device for winding the welding wire 10 onto the ear pin 20 3. The frame 1 is also provided with a welding device 4 for placing the decorative part 30 and welding the decorative part 30 and the ear pin 20 wound with the welding wire 10 together. The frame 1 is provided with a welding device 4 for The tray 5 containing the flux, and the frame 1 is also provided with a soldering device for dipping the ear needle 20 wrapped with the welding wire 10 into the flux and grabbing the ear needle 20 dipped in the flux to the welding device 4 of the ear acupuncture grasping device 6 . The welding wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com