Extrusion roller hole pattern of high-frequency welded pipe rolling mill

A technology of high-frequency welded pipe and squeeze roller, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of uneven heating of steel pipe, poor welding quality of steel pipe, cracking of welding joint of steel pipe, etc., to achieve good welding quality, Good quality steel pipe and uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

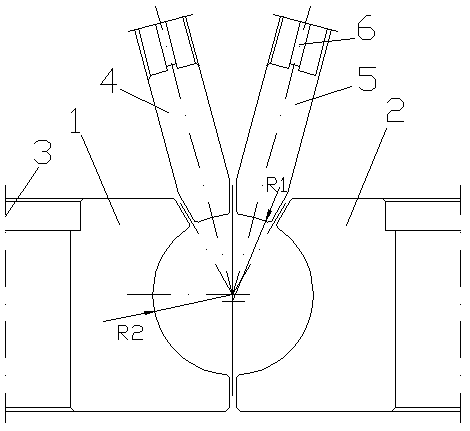

[0010] Such as figure 1 As shown, the present invention is an extrusion roll pass of a high-frequency welded pipe mill, including a pair of extrusion side rolls 1, 2, and a pair of extrusion side rolls with the same structure installed side by side. Upper roller one 4, extrusion upper roller two 5, said extrusion side roller one 1, extrusion side roller two 2 are installed on the side roller shaft 3 through keys, said extrusion upper roller one 4, extrusion The upper roller 2 5 is installed on the upper roller frame shaft 6 through bearings, the inner arc radius of the extrusion upper roller 1 4 and the extrusion upper roller 2 5 is R1, the extrusion side roller 1 and the extrusion The inner arc radius of the side roll 2 is R2, the R1 is greater than R2, and the preferred R1 is equal to 1.2 times of R2. The inner arc radius R2 has a certain amount of deviation, so that the two ports at the welding joint of the steel pipe are in a flat state, the inner and outer layers of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com