An X-ray object image point autonomous precision tracking control system and method

A tracking control and control system technology, applied in the general control system, control/regulation system, adaptive control, etc., can solve the problems of smaller magnification, image distortion, and larger range, so as to achieve clear and accurate X-ray imaging The effect of small deviation of affine change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

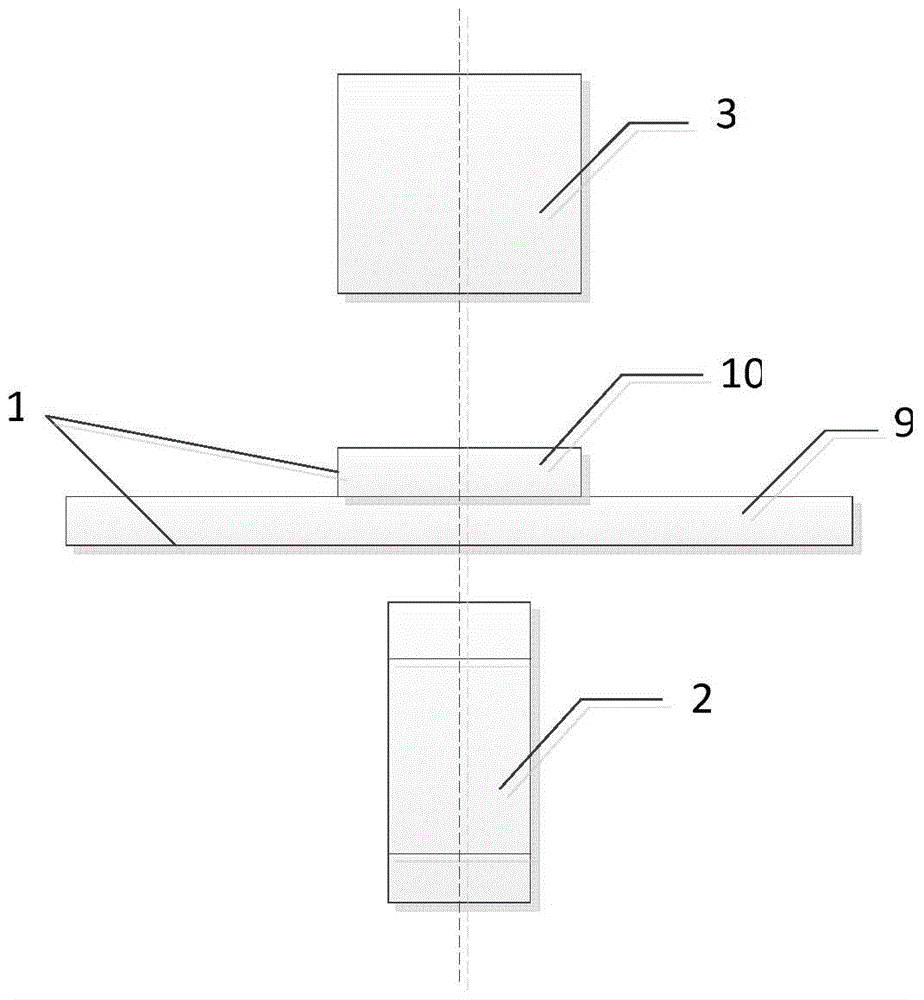

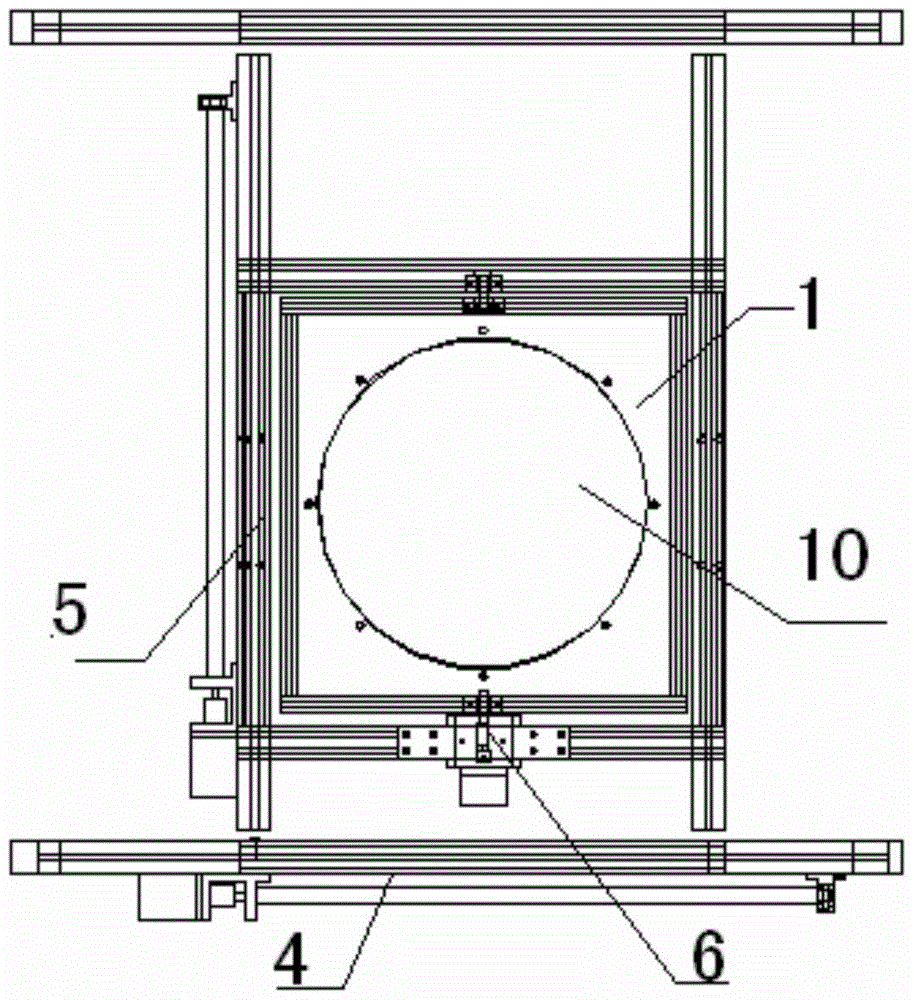

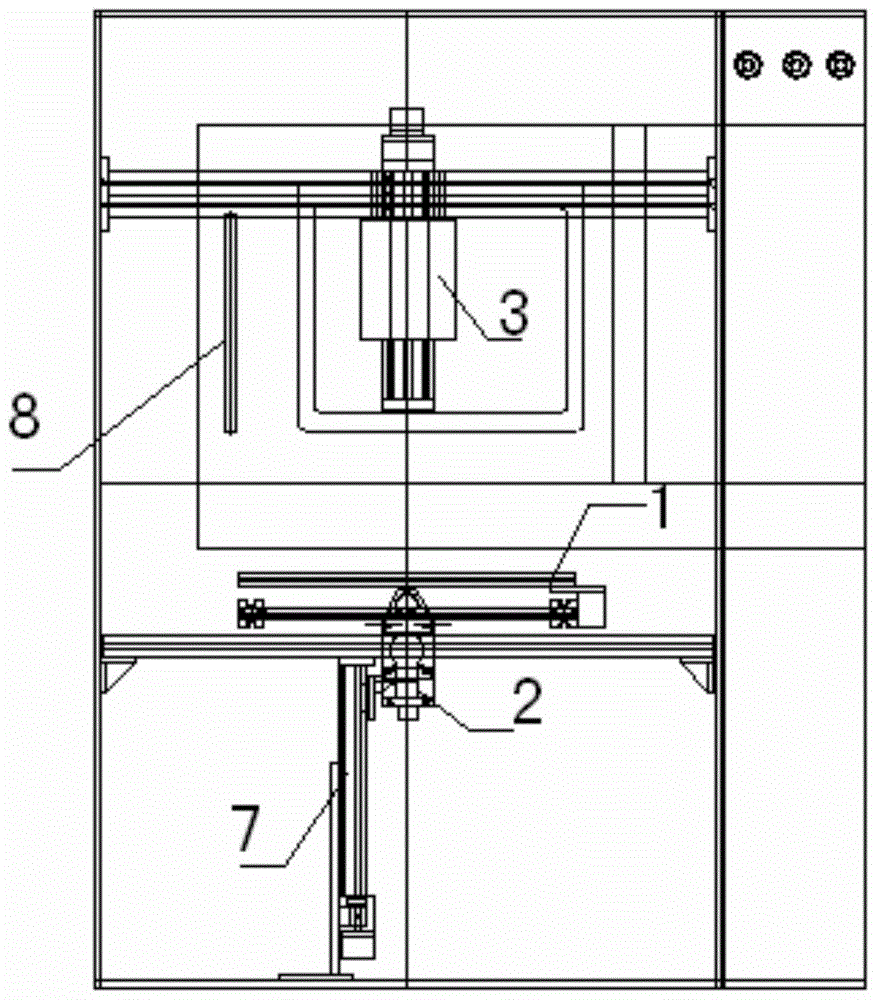

[0069] An autonomous precision tracking control system for X-ray object image points, such as figure 1 , 2 , 3, including stage 1, transmission device, ray generating device 2, image detector 3, image processing device, built-in measuring device and control system, wherein

[0070] The stage 1 includes a fixing part 9 and a tray 10 which is arranged on the fixing part 9 and can rotate 360 degrees, and the object to be measured is placed on the tray 10;

[0071] The transmission device includes X-axis 4, Y-axis 5, Z-axis and R-axis 6 respectively connected to the stage fixture 9, wherein X-axis 4 drives the stage 1 to move left and right, and Y-axis 5 drives the stage 1 Back and forth movement, Z axis drives the stage 1 to rise and fall, R axis 6 drives the stage 1 to rotate left and right by 60 degrees, the rotating shaft fixedly connected to the tray 10 drives the tray to rotate 360 degrees, and drives the ray generating device 2 to rise and fall Axis one 7, transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com