Fault Diagnosis Method of Rail Grinding Car

A rail grinding car and fault diagnosis technology, applied in electrical testing/monitoring, etc., can solve the problems of low efficiency and inability to monitor the real-time remote monitoring of the working status of rail grinding cars, so as to improve efficiency, realize remote monitoring and diagnosis, and ensure accuracy Effects of Sex and Integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

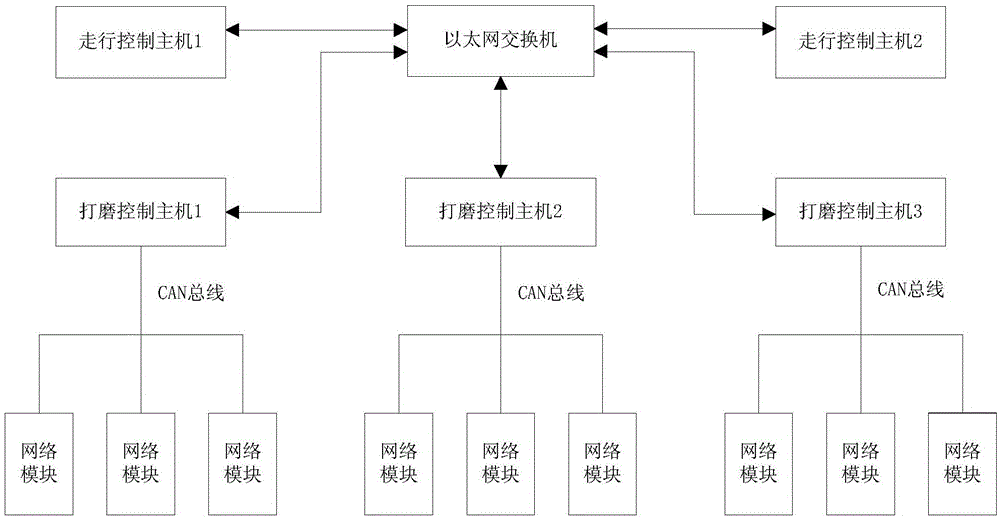

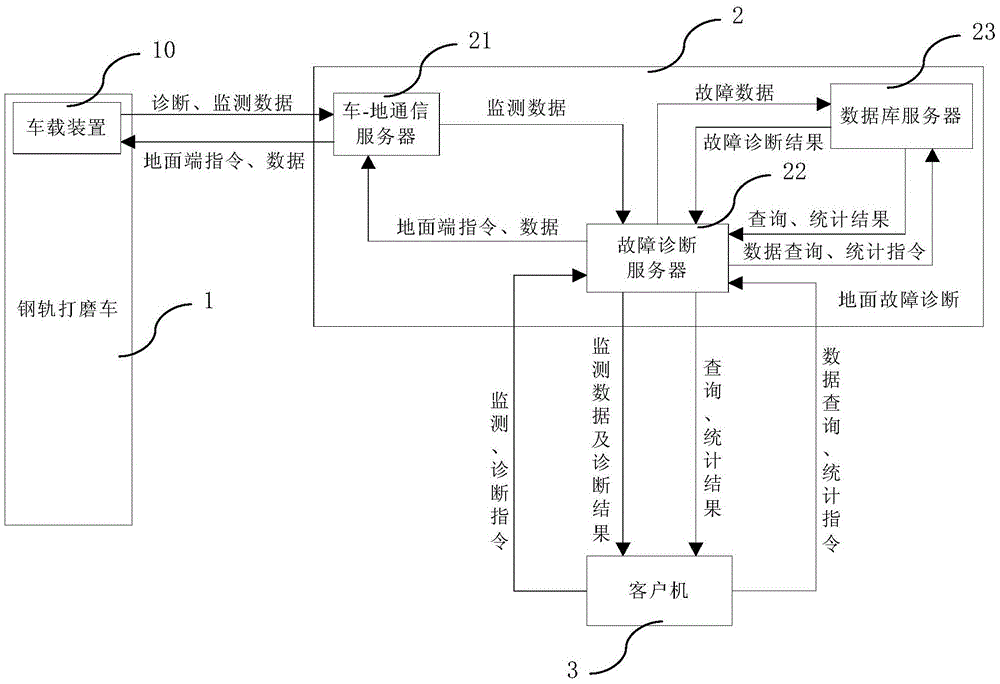

[0098] Embodiment 1: as attached figure 2 and 3 As shown, a specific embodiment of a rail grinding vehicle fault diagnosis method based on the above-mentioned rail grinding vehicle fault diagnosis system, the rail grinding vehicle fault diagnosis system includes: a vehicle-mounted device 10 and a ground server 2, and the vehicle-mounted device 10 is arranged on the rail grinding vehicle 1 superior. The rail grinding car 1 further includes a switch 11, a network system, a grinding control host 12 and a travel control host 13, and the vehicle-mounted device 10, the switch 11, the grinding control host 12 and the travel control host 13 are connected through the network system. Ground server 2 comprises car-ground communication server 21, fault diagnosis server 22, and this method comprises the following steps:

[0099] (A) The vehicle-mounted device 10 obtains the monitoring and / or diagnosis information of the grinding control host 12 and the running control host 13 through th...

Embodiment 2

[0103] Embodiment 2: on the basis of foregoing specific embodiment, step (D) further comprises the following steps:

[0104] Store information including rail grinding vehicle failure phenomena, failure causes and failure solutions to form a diagnostic expert database, and store information including vehicle failure records and vehicle maintenance records to form a historical database;

[0105] The fault diagnosis server 22 automatically expands the diagnostic expert database according to the user's method of troubleshooting and solving the fault of the rail grinding vehicle 1, or the user expands the diagnostic expert database according to the actual situation.

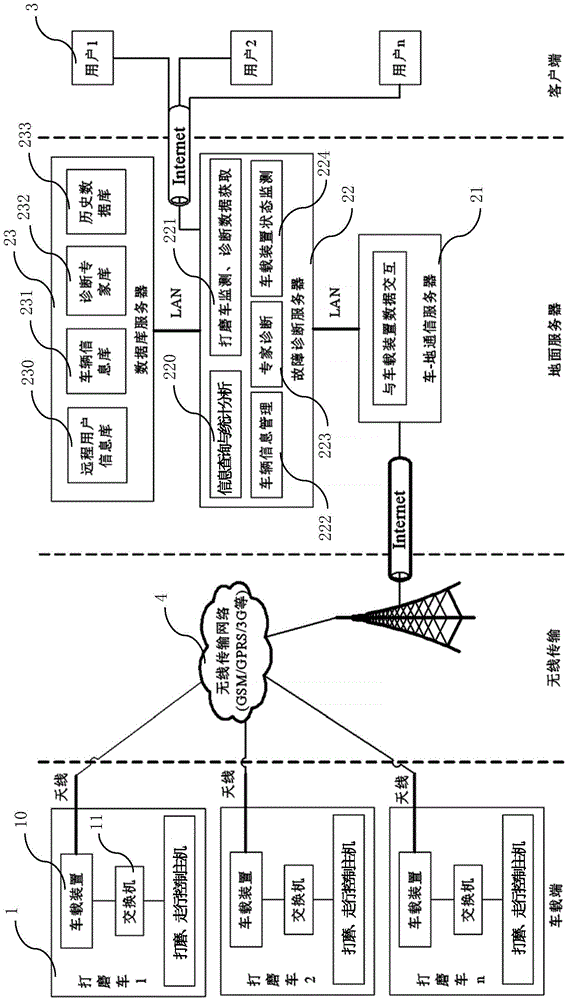

[0106] as attached Image 6 , 7 As shown in and 8, in step (D), when the user chooses to perform fault diagnosis on the rail grinding vehicle 1, the fault diagnosis server 22 sends a diagnosis command to the vehicle-mounted device 10 through the vehicle-ground communication server 21, and the vehicle-mounted device 1...

Embodiment 3

[0107] Embodiment 3: as attached Figure 4 and 5 As shown, on the basis of the foregoing specific embodiments, in step (A), the vehicle-mounted device 10 is connected to the Ethernet of the rail grinding car 1 through the switch 11, and listens to the grinding control host 12 and the travel control host 13 to send to The data in the network, from which the monitoring and diagnosis information of the rail grinding car 1 is collected and saved, and the fault analysis is carried out, so as to obtain the fault occurrence information and fault type. There are two ways to analyze the fault phenomenon of rail grinding car 1:

[0108] (a) Direct analysis method, that is, directly use the diagnosis result of the grinding control host 12 (according to the fault flag bit) to determine the occurrence of the fault, such as the underlying modules (AI module, AO1 module, DO module and DI module) are used to indicate a certain Faulty digital input signals, offline and error status of underl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com