High-pressure resistant and corrosion resistant turbine flowmeter

A turbine flowmeter, corrosion-resistant technology, applied in the direction of volume measurement, flow/mass flow measurement, liquid/fluid solid measurement, etc., can solve the problems of poor corrosion resistance, increase manufacturing costs, limit applications, etc., to meet the requirements of magnetic permeability and The effect of corrosion resistance requirements, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

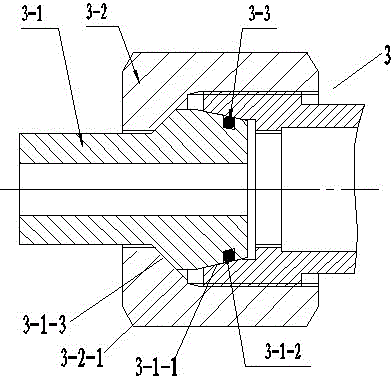

[0011] Such as figure 1 , 2 , 3, and 4, a high-pressure and corrosion-resistant turbine flowmeter includes a preamplifier 1, a sensor 2, and a high-pressure sealing structure 3. The high-pressure sealing structure 3 includes a connecting pipe 3-1, a compression nut 3- 2. O-ring 3-3, one end of the connector of the connecting pipe 3-1 is a conical surface I3-1-1, and a groove 3-1-2 is provided on the conical surface I3-1-1, and the connecting pipe The other end of the 3-1 connector is a tapered surface II3-1-3, the O-ring 3-3 is set in the groove 3-1-2, and one end of the connecting pipe 3-1 penetrates the compression nut 3-2 The conical surface II3-1-3 of its connecting pipe 3-1 joint in the middle hole matches the conical surface III3-2-1 in the compression nut 3-2 hole.

[0012] Sensor 2 includes housing 2-1, guide 2-2, impeller 2-3, impeller shaft 2-4, compression ring 2-5, impeller shaft 2-4 and impeller 2-3 hole interference fit assembly, impeller 2-3 is set in the she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com