Two-shaft friction disc brake clutch for twin-turbine torque converter planetary gearbox

A brake clutch and torque converter technology, applied in the combination of coupling and brake, brake type, liquid resistance brake, etc., can solve the problems of poor operating comfort and large shifting impact, and overcome the large shifting impact , Reliable performance, low cost of manufacture and improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

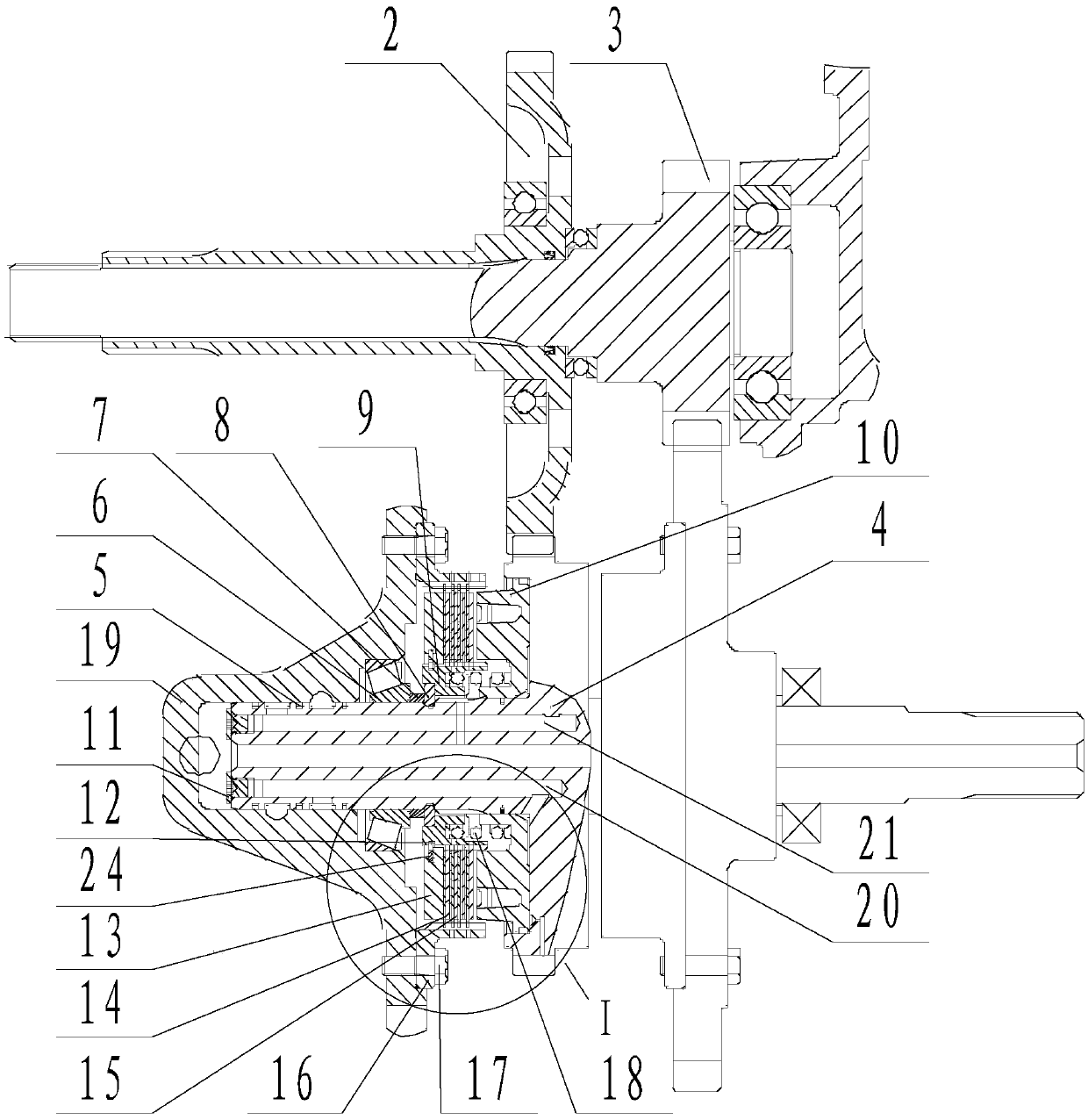

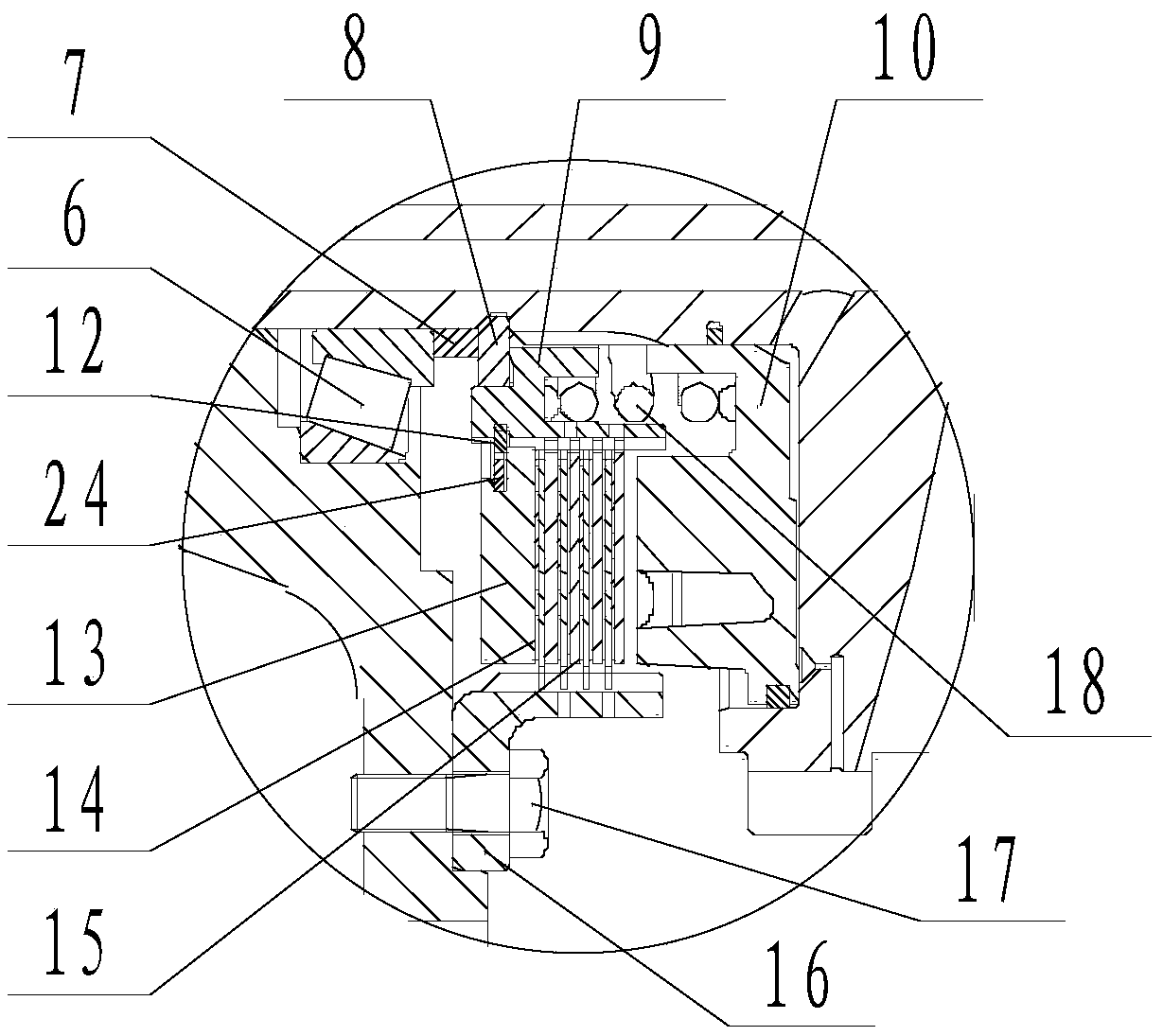

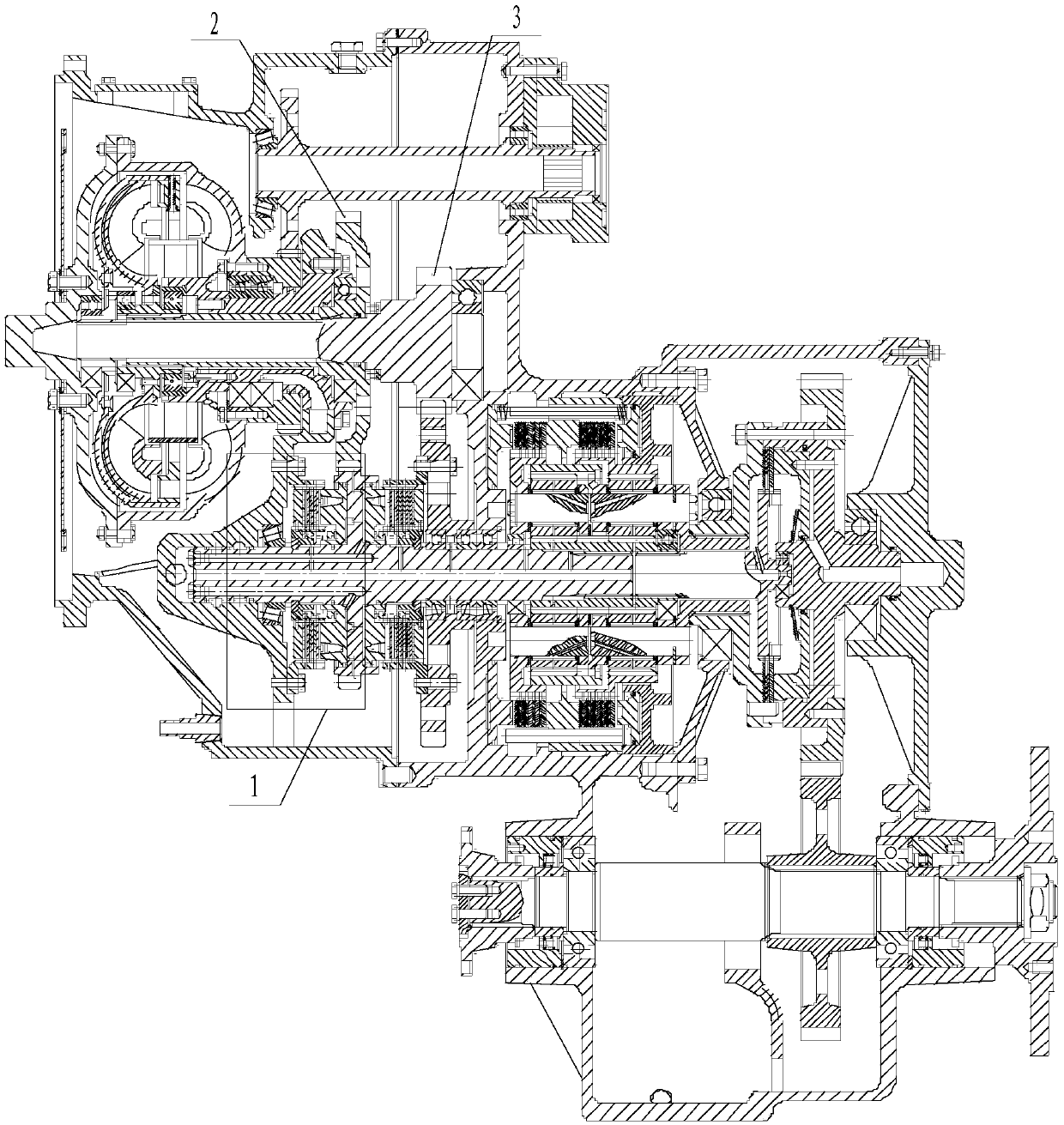

[0019] A two-shaft friction disc brake clutch for a twin-turbine torque converter planetary gearbox, installed on the intermediate input shaft assembly 4 in the twin-turbine torque converter planetary gearbox, the two-shaft friction disc brake clutch The dynamic clutch includes a rolling bearing 6, a clutch hub 9, a piston 10, a pressure plate 13, a driving friction plate 14, a driven friction plate 15, a clutch housing 16, and a spring 18. The piston 10 is movably installed on the intermediate input shaft assembly 4 through the piston ring 5 Above, the intermediate input shaft assembly 4 is connected to the clutch hub 9 through splines, the clutch hub 9 is connected to the driven friction plate 15 through splines, the clutch housing 16 is connected to the driving friction plate 14 through splines, and the pressure plate 13 passes through The spline is connected with the clutch hub 9 and positioned by the snap ring A12 and the snap ring B24. The intermediate input shaft assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com