Low-cost high-performance corrosion-resistant steel bar and its manufacturing method

A manufacturing method and high-performance technology, applied in the field of low-cost high-performance corrosion-resistant steel bars and their manufacture, can solve the problems of high price, difficult welding, limited corrosion resistance improvement, etc., achieve good cost performance, facilitate large-scale promotion, and stabilize The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

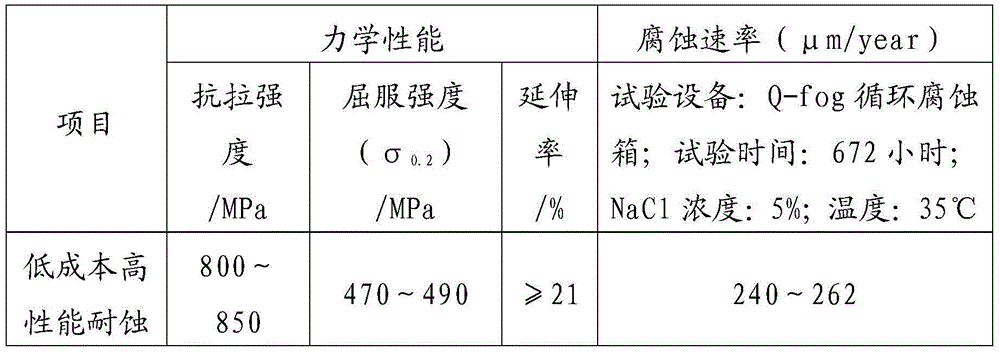

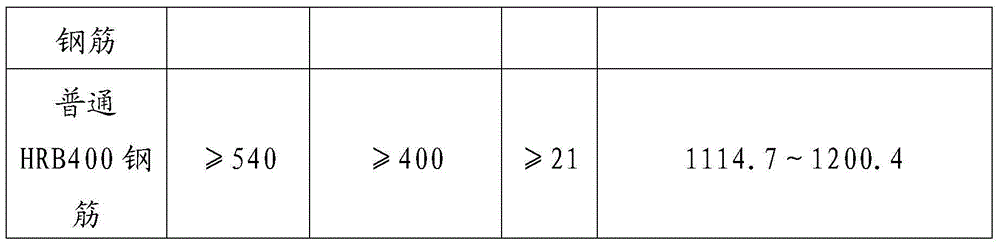

[0033] The steel composition of the embodiment of the invention and the comparative example is shown in Table 2

[0034]

[0035] Comparison 1 is industrially produced ordinary HRB400 steel bar; Comparison 2 is industrially produced ordinary corrosion-resistant rebar.

[0036] The technological process of the present invention is: hot metal desulfurization pretreatment → electric furnace or top-bottom combined blowing converter smelting → out-of-furnace refining → continuous casting → casting billet heating → rolling → cooling bed air cooling → cut-to-length shear → storage, specifically;

[0037] A. Hot metal desulfurization pretreatment, using molten iron tank to stir desulfurization, control the sulfur content of molten iron into the electric furnace or converter [S]≤0.015%;

[0038] B. The molten iron in step A is sent to the electric furnace or the top-bottom combined blowing converter for conventional smelting with scrap steel and slagging materials. The end-point carbon content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com