Preparation method of aqueous daylight fluorescent pigment color paste

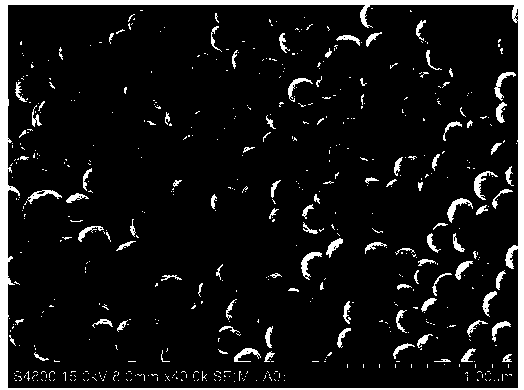

A fluorescent pigment and sunlight technology, applied in the direction of pigment paste, etc., can solve the problem of color expansion control of color paste that is not mentioned, and achieve the effect of bright color, excellent covering rate and uniform particle size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of water-based yellow sunlight fluorescent pigment paste, comprising the following steps:

[0033] Put a four-necked flask equipped with a stirrer, a thermometer, and a reflux condenser in a water bath at 50°C, add 40g of water, 1g of hydroxyethyl cellulose, 1g of gelatin, 0.5g of clay, and 0.5g of Sodium dodecylbenzenesulfonate, 6g of isomeric tridecyl alcohol polyoxyethylene ether, 1.5g of coumarin 16, and 1g of low molecular weight polymethyl methacrylate were stirred and dissolved evenly to form a uniform dispersion system.

[0034] Then add 20g styrene, 15g acrylonitrile, 3g hydroxyethyl methacrylate, 2g hydroxypropyl methacrylate to the dispersion system, stir at high speed to form a uniform pre-emulsion; Ammonium sulfate and 0.4g ascorbic acid were reacted for 4 hours, cooled to 50°C, 0.24g tert-butyl hydroperoxide and 0.3g ascorbic acid were added respectively, and reacted for 0.5h to obtain a yellow daylight fluorescent pigment paste.

[0...

Embodiment 2

[0036] A preparation method of water-based red sunlight fluorescent pigment paste, comprising the following steps:

[0037] Place a four-necked flask equipped with a stirrer, a thermometer, and a reflux condenser in a water bath at 50°C, add 40g of water, 1g of polyvinyl alcohol, 0.5g of methylcellulose, and 0.5g of calcium carbonate to the four-necked flask , 11g sodium lauryl sulfate, 4g oleyl alcohol polyoxyethylene ether, 1g rhodamine 3G, 1g low molecular weight polymethyl methacrylate, stir and dissolve to form a uniform dispersion system; then add to the dispersion system 25g styrene, 12g acrylonitrile, 2g glycidyl methacrylate, 1g ethyl methacrylate, high-speed stirring to form a uniform pre-emulsion; heat up to 75°C, then add 0.4g potassium persulfate and 0.53g ascorbic acid respectively, After reacting for 4 hours, lower the temperature to 50°C, add 0.24g of tert-butyl hydroperoxide and 0.3g of ascorbic acid respectively, and react for 0.5h to obtain red daylight fluo...

Embodiment 3

[0039] A preparation method for water-based orange sunlight fluorescent pigment paste, comprising the following steps:

[0040] Place a four-necked flask equipped with a stirrer, a thermometer, and a reflux condenser in a water bath at 50°C, add 40 g of water, 1 g of bentonite, 1 g of polyvinylpyrrolidone, 0.5 g of calcium phosphate, and 0.3 g of alkane into the four-necked flask. Sodium phenol polyoxyethylene sulfate, 3g sodium polyoxyethylene ether sulfate, 2g oily nonylphenol polyoxyethylene ether, 0.5g fluorescent red F5G, 0.28g rhodamine 3B, 0.53g coumarin 16, 1.5g low molecular weight Polymethyl methacrylate, stir and dissolve evenly to form a uniform dispersion system; then add 30g styrene, 7g acrylonitrile, and 3g ethyl acrylate to the dispersion system, stir at high speed to form a uniform pre-emulsion; heat up to 65°C, Then add 0.3g ammonium persulfate and 0.4g ascorbic acid respectively, react for 4 hours, cool down to 50°C, add 0.24g tert-butyl hydroperoxide and 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com