Conductive ink for regulating power as well as preparation method and application of conductive ink

A technology of conductive ink and power adjustment, applied in the direction of ink, application, household appliances, etc., can solve the problem that conductive ink cannot produce good results, and achieve the effect of ensuring performance, reducing temperature control components, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

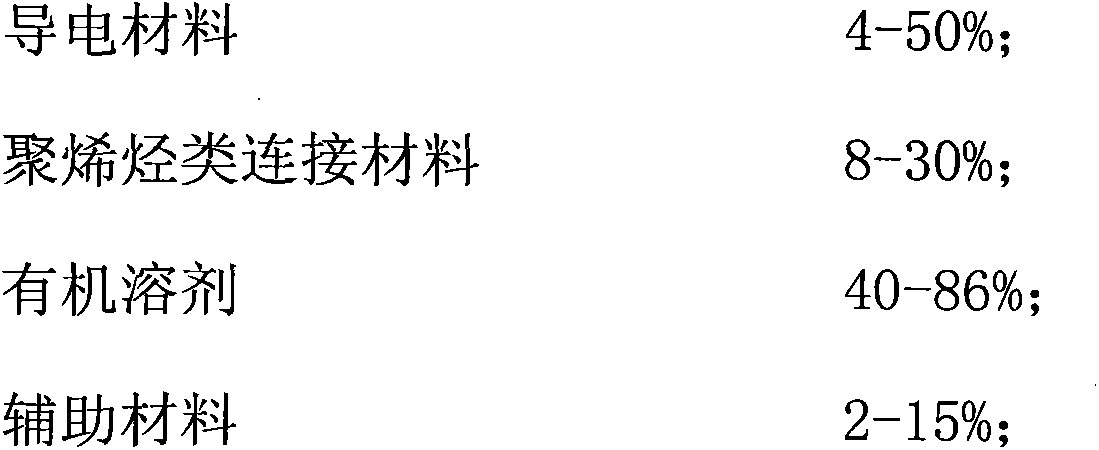

[0034] A conductive ink for regulating power, comprising the following components:

[0035]

[0036] The preparation method of the conductive ink for regulating power is as follows:

[0037] 1. Mix highly conductive carbon black into highly crystalline high-density polyethylene, and make granules after thorough mixing at a high temperature of 200°C.

[0038] 2. Cross-link the prepared particles through nuclear irradiation, so that carbon black and high-density polyethylene can be stably cross-linked and prevent carbon black from migrating. If the carbon black migration will cause the product to undergo irreversible changes in electrical conductivity during high and low temperature cycles.

[0039] 3. Pulverize the cross-linked particles with a pulverizer to achieve an average particle size of less than 1 mm.

[0040] 4. Grind the particles with an average particle size of less than 1 mm to 0.2-200 microns with a jet mill.

[0041] 5. Put the pulverized micropowder into a...

Embodiment 2

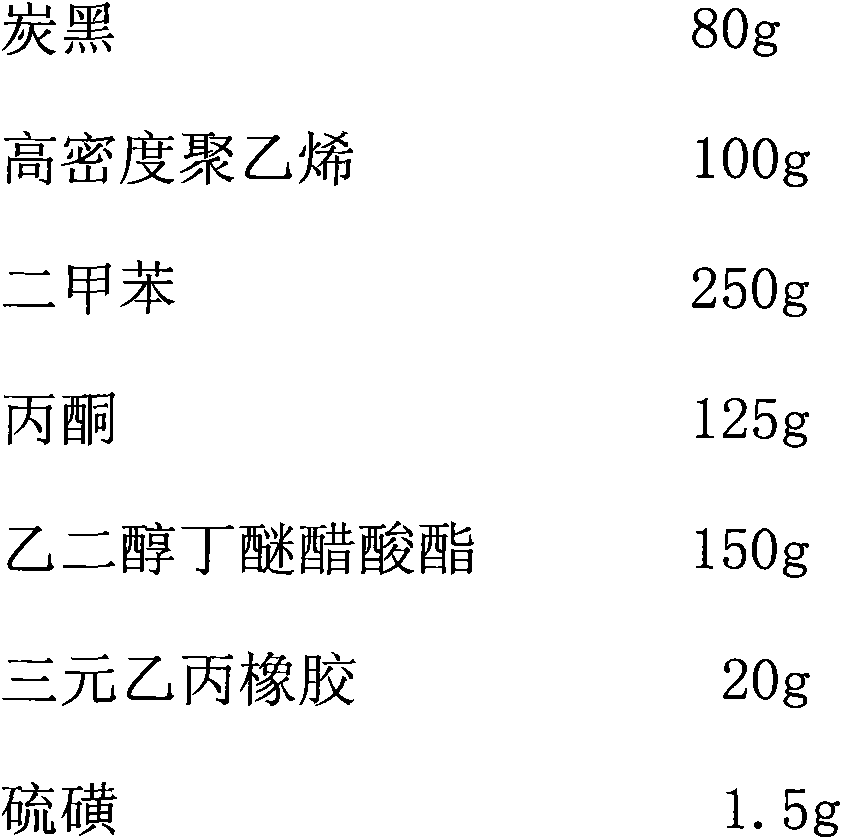

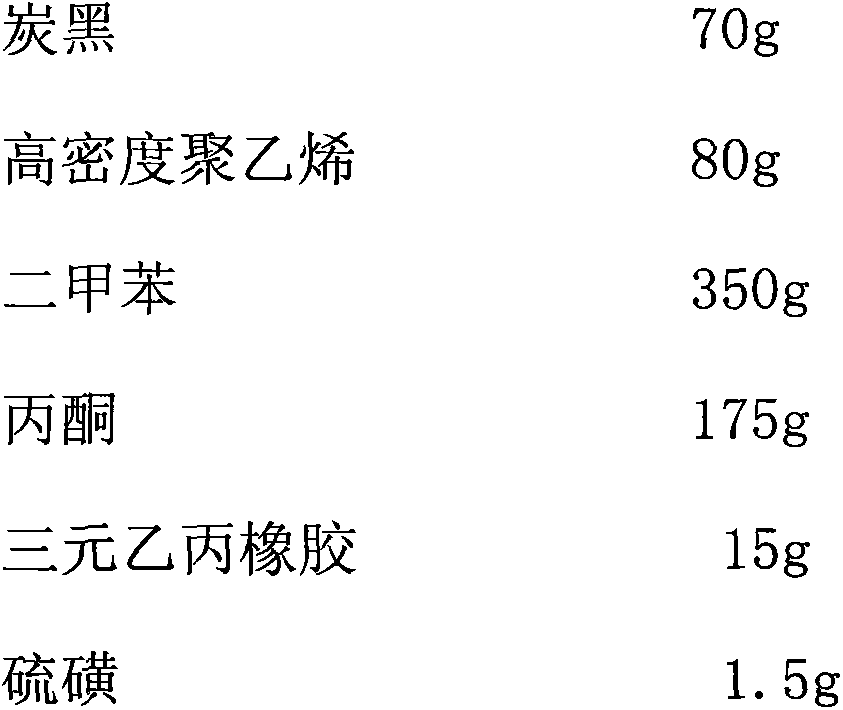

[0045] A conductive ink for regulating power, comprising the following components:

[0046]

[0047] The preparation method of the conductive ink for regulating power is as follows:

[0048] 1. Mix highly conductive carbon black into highly crystalline high-density polyethylene, and make granules after thorough mixing at a high temperature of 200°C.

[0049] 2. Cross-link the prepared particles through nuclear irradiation, so that carbon black and high-density polyethylene can be stably cross-linked and prevent carbon black from migrating. If the carbon black migration will cause the product to undergo irreversible changes in electrical conductivity during high and low temperature cycles.

[0050] 3. Pulverize the cross-linked particles with a pulverizer to achieve an average particle size of less than 1 mm.

[0051] 4. Grind the particles with an average particle size of less than 1 mm to 0.2-200 microns with a jet mill.

[0052] 5. Put the crushed micropowder into a mi...

Embodiment 4-6

[0061] Each embodiment prescription is as follows: preparation method is the same as embodiment 1

[0062]

[0063] In conclusion, the conductive inks for adjusting power prepared in Examples 4-6 all have PTC performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com