Polyamide (PA) composition

A polyamide composition and polyamide technology, applied in the field of polyamide, can solve the problems that the strength and toughness cannot be improved at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the functionalized ABS toughening agent of the present invention: first, pre-emulsify monomer styrene (St), acrylonitrile (AN) and glycidyl methacrylate (GMA), the specific steps are: Add St, AN and GMA into the monomer bottle, then add rosin soap and distilled water into the monomer bottle, seal it with a rubber stopper and shake the monomer bottle until the liquid in the bottle is in the form of a non-layered emulsion, that is, the monomer For the mixed liquid, the volume ml of the rosin soap liquid: the mass g of styrene is 10: (17.25-21.75), and the mass ratio of distilled water to styrene is 10: (17.25-21.75).

[0029] In the present invention, polybutadiene latex (solid content: 57.32%) is first put into a three-necked bottle, diluted with distilled water to a solid content of 35.0%, and continuously stirred under the condition of nitrogen protection and 62-67°C, in order to better disperse Initiation, the above-mentioned monomer mixed so...

Embodiment 1

[0034] 60 parts by weight of the dried PA6 granular material and 10 parts by weight of the dry functionalized ABS toughening agent powdery material are placed in a high mixer and mixed, wherein the core-shell ratio of the functionalized ABS modifier is 70 / 30, The rubber phase is PB, the shell layer is a copolymer of St, AN and GMA, and its weight ratio is 73 / 24 / 3. The premix and 30 parts by weight of glass fiber are added to the co-rotating twin-screw extruder for reaction to obtain a polyamide composition. The screw speed is 450 rpm. From the feed port to the die head The reaction temperatures of each reaction section are 200°C, 215°C, 245°C, 255°C, 250°C, 260°C, 260°C, 260°C, and 255°C.

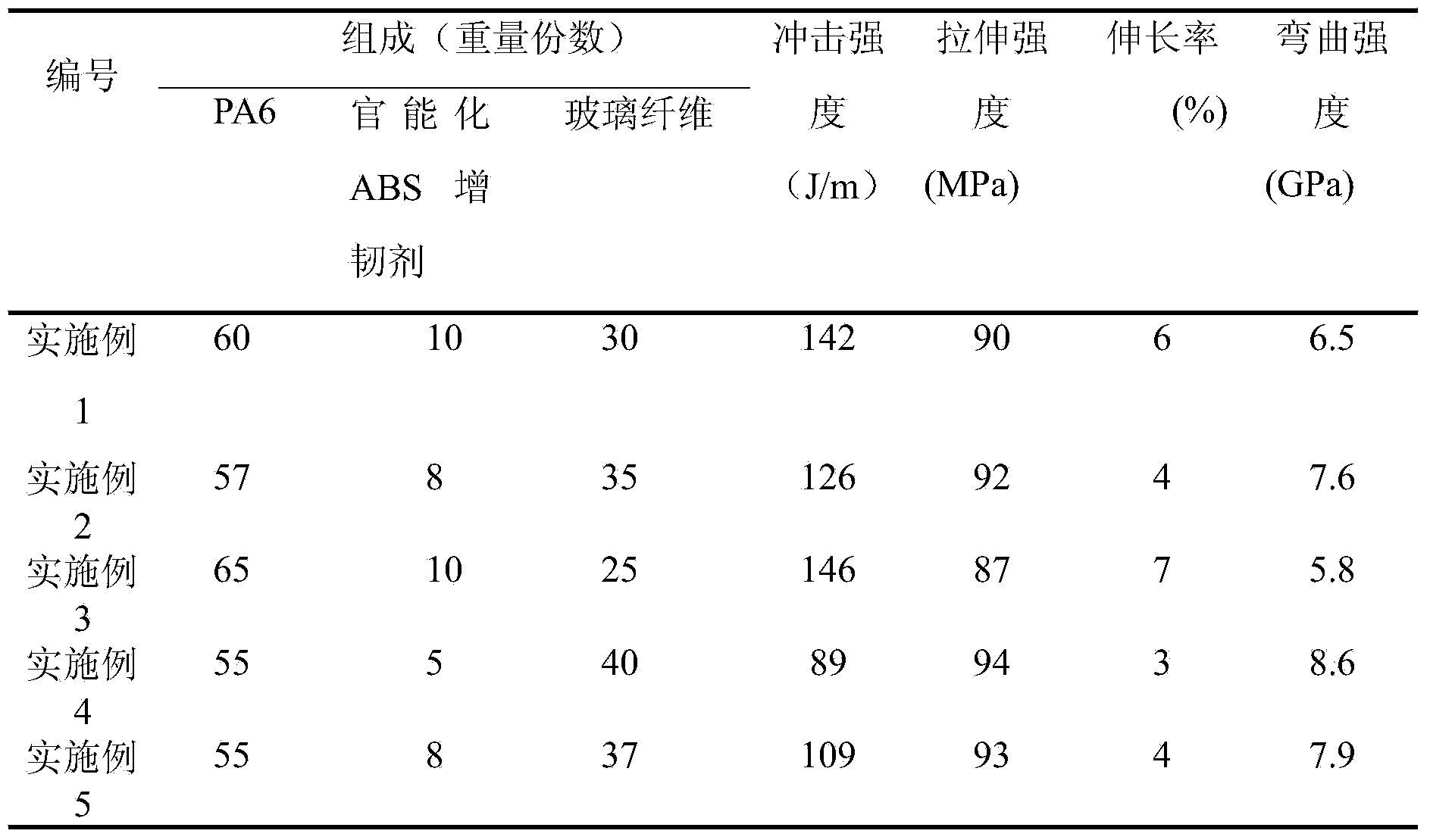

[0035] Tensile and impact samples were made by injection molding method at 240-255 °C, and the test results of their mechanical properties are shown in Table 1.

Embodiment 2

[0037] According to the steps and conditions of Example 1, only the parts by weight of PA6 were changed to 57, the parts by weight of the functionalized ABS toughening agent were 8, and the parts by weight of glass fibers were 35. The properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com