Thermo-sensitive composite material, as well as preparation method and application thereof

A composite material, temperature-sensitive technology, applied in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve problems such as delaying the best time to deal with problems, unable to locate the local temperature of hot spots in a timely and accurate manner, etc. The effect of timely and accurate alarm, stable performance and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The temperature-sensitive composite material is composed of 1.5% polyacrylamide, 8% ammonium bicarbonate, 0.5% sodium dodecylbenzenesulfonate, and 90% water. Ammonium bicarbonate and sodium dodecylbenzene sulfonate are dissolved in water to make an aqueous solution, polyacrylamide is added, and left to stand for 0.5 hours to form a paste-like temperature-sensitive composite material.

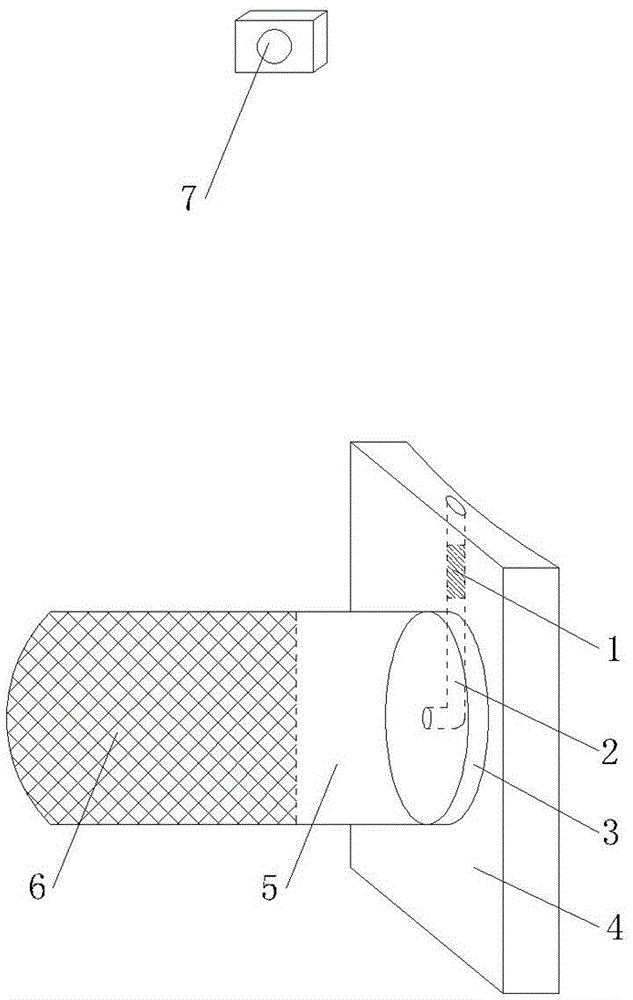

[0028] The structure of the overheating alarm device is as follows: figure 1 As shown, it consists of three parts: a base 4 made of aluminum alloy and easy to conduct heat; a container 5 made of hard corrosion-resistant plastic for holding composite materials 6 ; and a gas-sensitive alarm device 7 .

[0029] Put the temperature-sensitive composite material 6 into the container 5, connect and assemble it on the base 4 through the thread 3, and seal the joint with a sealing rubber ring. The bottom surface of the base 4 is set in an inner arc shape, and a slender through hole 2 with a lengt...

Embodiment 2

[0033] Polyvinyl alcohol 2%, ammonia 15%, water 93%. Dissolve ammonia water in water to form an aqueous solution, add polyvinyl alcohol, and let it stand for 0.5 hours to form a paste-like temperature-sensitive composite material.

Embodiment 3

[0035] Ammonium polyacrylate 1%, 95% ethanol 10%, water 89%. Dissolve 95% ethanol in water to make an aqueous solution, add polyacrylic acid amine, and let it stand for 0.5 hours to form a paste-like temperature-sensitive composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com