Amino functionalized mesoporous macromolecular small nanosphere and preparation method thereof

A technology of nano-spheres and amino functions, which is applied in the field of amino-functionalized mesoporous polymer nano-spheres and its preparation, which can solve the problems of heavy workload, constraints, unfavorable mass transfer and diffusion, and achieve high yield and easy operation easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

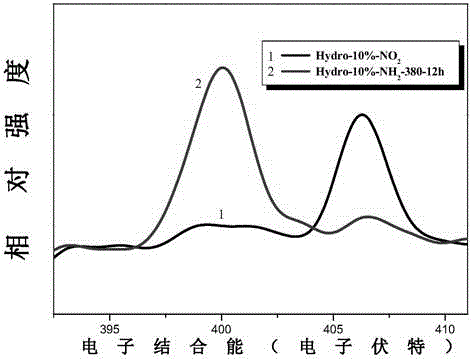

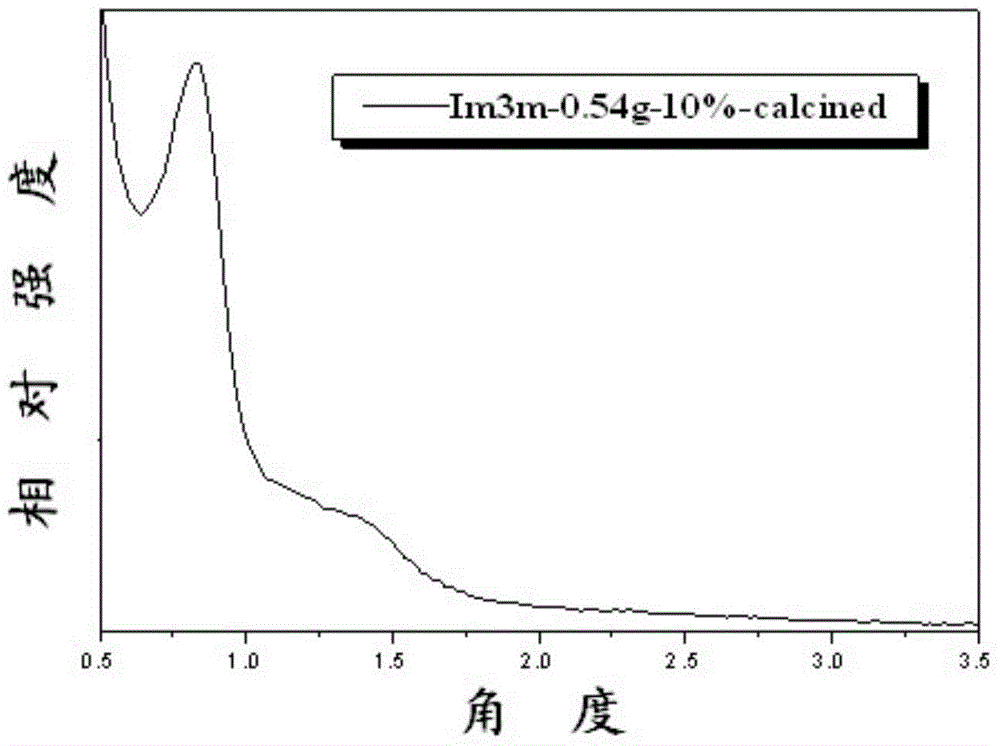

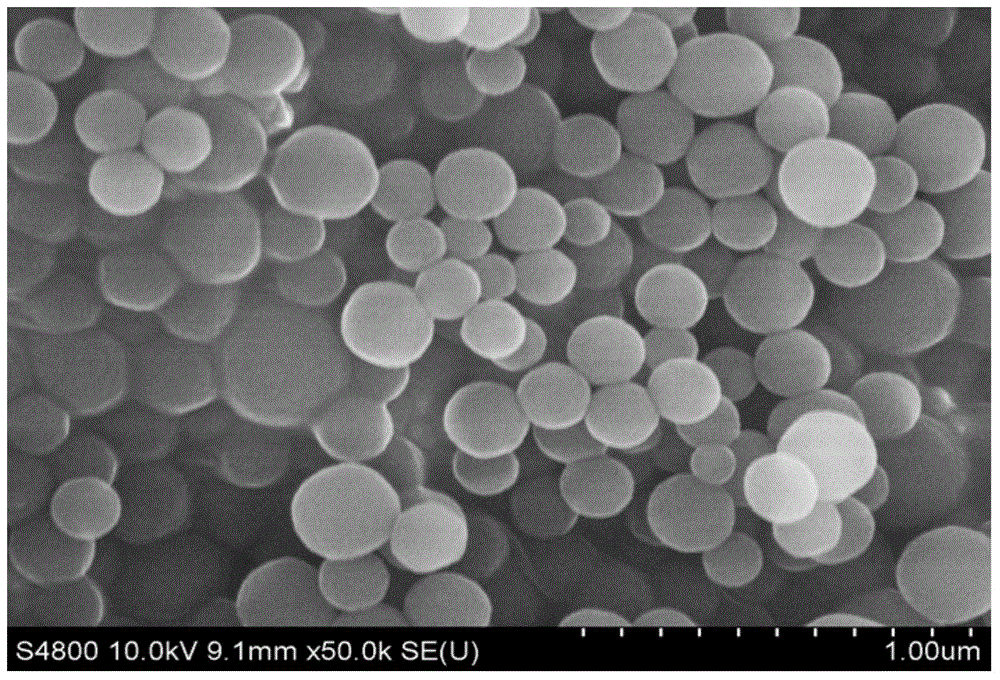

[0030] In a nutshell, the present invention is based on the organic-organic self-assembly strategy, selects triblock copolymer F127 (polyethylene oxide-polypropylene oxide-polyethylene oxide) as a surfactant, and uses phenol, m-nitrogen Based on phenol and formaldehyde as macromolecular monomers, the chemical composition of amino-functionalized ordered mesoporous phenolic resin materials was realized by changing the ratio or concentration of macromolecular monomers and experimental process conditions by using hydrothermal method combined with in-situ one-step post-reduction technology , effective control of pore structure and morphology, to obtain ordered functionalized mesoporous materials with high amino content, large specific surface area and spherical short pores, that is, amino functionalized mesoporous polymer nanospheres, which are expected to be used in gas Storage, heavy metal ion adsorption, organic catalysis and other aspects have been widely used.

[0031] The tec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com