Preparation method and application of surface molecular imprinting solid-phase adsorbent for psychiatric drugs

A technology of surface molecular imprinting and solid-phase adsorption, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of low binding recognition efficiency, failure to overcome, and template molecule embedding too deep, and improve the imprinting efficiency and adsorption. The effect of desorption rate, change of reaction monomer species, and reduction of entrapment phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

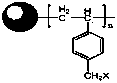

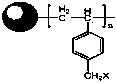

[0027] Embodiment 1: A method for preparing a molecularly imprinted solid-phase adsorbent on the surface of psychotropic drugs, which is characterized in that the surface-induced atom transfer radical polymerization method is adopted on the surface of the polymer resin: the method is firstly to chloromethyl on the surface of the styrene resin Chemical preparation of macromolecular initiator: take 5 g of pretreated styrene resin (particle size 03-1.25 mm) into a flask, add 8 g of paraformaldehyde, 15 g of anhydrous zinc chloride, and 30 mL of 80% concentrated sulfuric acid , 60 mL of glacial acetic acid, under the condition of 50-55 ℃ magnetic stirring, pass through self-made hydrogen chloride gas to react for 12 h. After the reaction, wash with a large amount of deionized water until neutral, wash with ethanol and acetone, and dry in vacuum at 50 ℃ 24 h, put it in a desiccator for later use, and then obtain the chloromethylated polystyrene resin; then prepare the barbiturate mo...

Embodiment 2

[0028]Embodiment 2: A method for preparing a molecularly imprinted solid-phase adsorbent on the surface of psychotropic drugs, which is characterized in that the surface-induced atom transfer radical polymerization method is adopted on the surface of the polymer resin: the method is first to chloromethyl on the surface of the styrene resin Chemical preparation of macromolecular initiator: take 10 g of pretreated styrene resin (particle size 03-1.25 mm) into a flask, add 10 g of paraformaldehyde, 20 g of anhydrous zinc chloride, 40 mL of 80% Concentrated sulfuric acid, 80 mL glacial acetic acid, under the condition of 50~55 ℃ magnetic stirring, pass through self-made hydrogen chloride gas to react for 12 h. Vacuum-dried for 24 h, and placed in a desiccator for later use, the chloromethylated polystyrene resin can be obtained. Then, the preparation of benzodiazepine molecularly imprinted solid-phase extraction agent: 5 mL methacrylic acid and 0.6 g benzodiazepine Zhuo was placed...

Embodiment 3

[0029] Example 3: A method for preparing a molecularly imprinted solid-phase adsorbent on the surface of psychotropic drugs, which is characterized in that the surface-induced atom transfer radical polymerization method is adopted on the surface of the polymer resin: the method is firstly to chloromethyl on the surface of the styrene resin Chemical preparation of macromolecular initiator: take 15 g of pretreated styrene resin (particle size 03-1.25 mm) into a flask, add 15 g of paraformaldehyde, 25 g of anhydrous zinc chloride, and 50 mL of 80% concentrated Sulfuric acid, 100 mL glacial acetic acid, under the condition of 50~55 ℃ magnetic stirring, pass through self-made hydrogen chloride gas to react for 12 h. Dry for 24 h and place in a desiccator for later use to obtain chloromethylated polystyrene resin; then prepare diazepam molecularly imprinted solid-phase extraction reagent: put 7 mL of acrylic acid and 0.8 g of diazepam at 250 mL of round bottom flask, add 20 mL of ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com