A kind of concrete with waste glass as main raw material and its preparation method

A technology of main raw material and waste glass, applied in the field of concrete, can solve the problems of unsatisfactory performance of concrete, inability to effectively improve the recycling rate of waste glass, etc., and achieve the effect of saving natural raw materials, excellent fluidity, and meeting strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

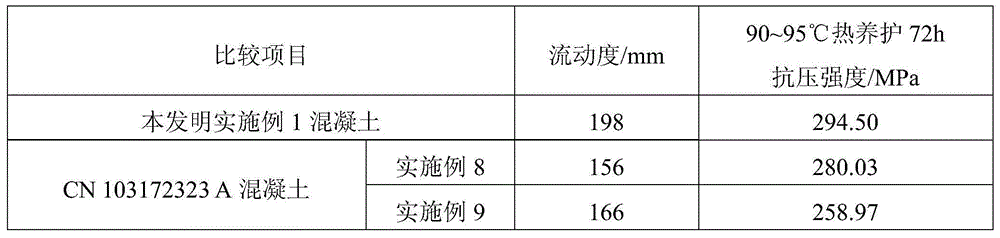

Embodiment 1

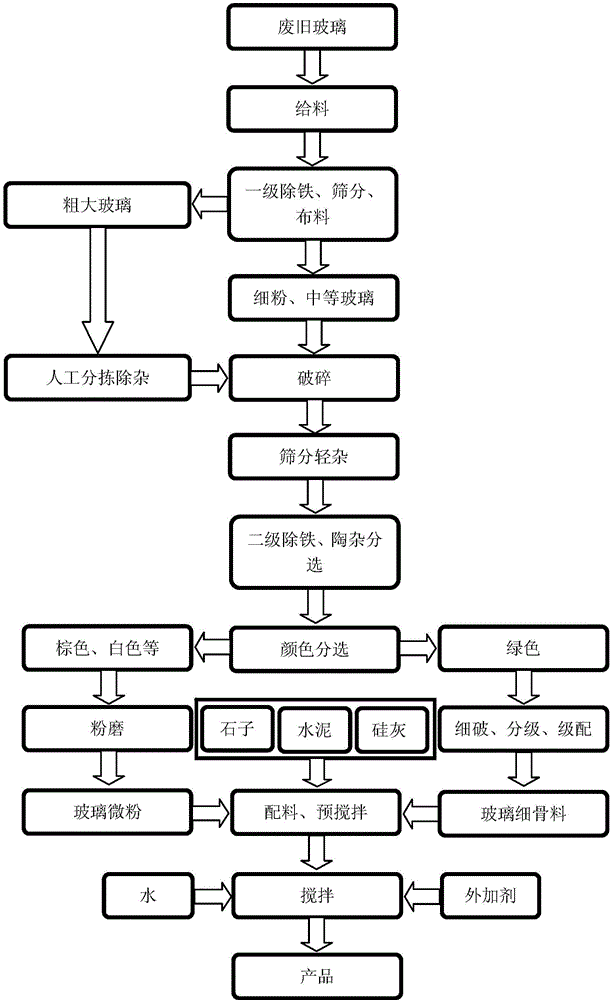

[0050] A kind of C30 waste glass concrete, the preparation steps are as follows:

[0051] A. Transport the waste glass to the hopper of the distributor.

[0052] B. Use a sieve distributor for primary iron removal, screening, and distribution.

[0053] C. During the conveying process of coarse glass, large-volume impurities are manually removed.

[0054] D. Use a waste glass crusher to break the screened fine powder, medium glass and coarse glass after manual sorting and removal of impurities.

[0055] E. Use a specific gravity sieve to screen the broken glass frit to remove light impurities.

[0056] F. Use a waste glass impurity sorter to remove metal impurities and ceramic opaque impurities in the glass frit.

[0057] G. Use a waste glass variegated sorter to separate the glass frit by color.

[0058] H. Use a vibrating mill to separate the brown, white and other glass frits separated by color and grind them into glass powder for use. The particle size of the glass powd...

Embodiment 2

[0067] A kind of concrete with waste glass as the main raw material is prepared according to the method of Example 1, except that steps J and K are as follows:

[0068] J. Ingredients and pre-mixing: Mix the prepared glass micropowder with glass fine aggregate, stones, cement, and silica fume according to the following proportions and add them to the mixer for pre-mixing for 30 seconds:

[0069] The total mass of the total adhesive (cement + glass powder + silica fume), glass fine aggregate, and stones (with a particle size of 5-16mm) is calculated as 100%, the total adhesive is 10wt%, the glass fine aggregate is 40wt%, and the stone is 50wt% .

[0070] The total mass of the total glue material (cement + glass powder + silica fume) is based on 100%, cement 70wt%, glass powder 20wt%, silica fume 10wt%.

[0071] K Stirring: Add the weighed admixture (1.2wt% of the total adhesive mass) and water (water-cement ratio 0.41) into the pre-mixed material and stir for 120s.

[0072] T...

Embodiment 3

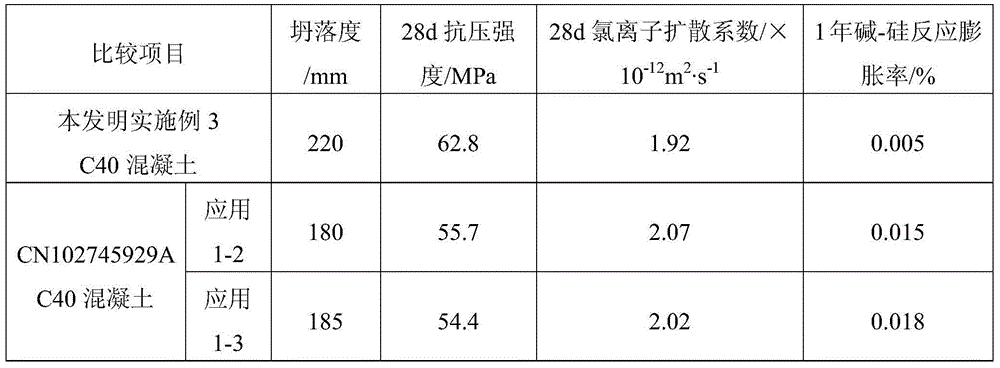

[0075] A kind of concrete with waste glass as the main raw material is prepared according to the method of Example 1, except that steps J and K are as follows:

[0076] J. Ingredients and pre-mixing: Mix the prepared glass micropowder with glass fine aggregate, stones, cement, and silica fume according to the following proportions and add them to the mixer for pre-mixing for 30 seconds:

[0077] The total mass of the total glue (cement + glass powder + silica fume), glass fine aggregate, and stones (with a particle size of 5-16mm) is calculated as 100%, the total glue is 25wt%, the glass fine aggregate is 33wt%, and the stone is 42wt% .

[0078] The total mass of the total glue material (cement + glass powder + silica fume) is based on 100%, cement 78wt%, glass powder 17wt%, silica fume 5wt%.

[0079] K Stirring: Add the weighed admixture (2.0wt% of the total rubber mass) and water (water-cement ratio 0.35) into the pre-mixed material and stir for 120s.

[0080] The obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com