Tire vulcanization inner mould

A technology of tire vulcanization and inner mold, which is applied to tires, household appliances, and other household appliances. It can solve problems such as structural asymmetry and incomplete expansion of the bladder, and achieve the effects of increasing the vulcanization pressure, solving incomplete expansion, and stabilizing the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

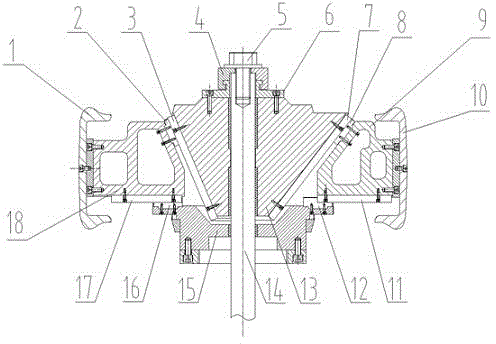

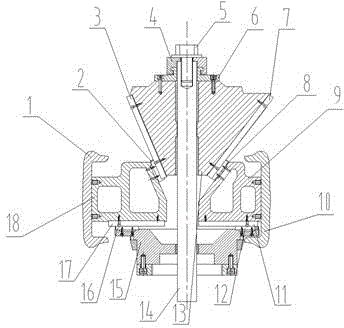

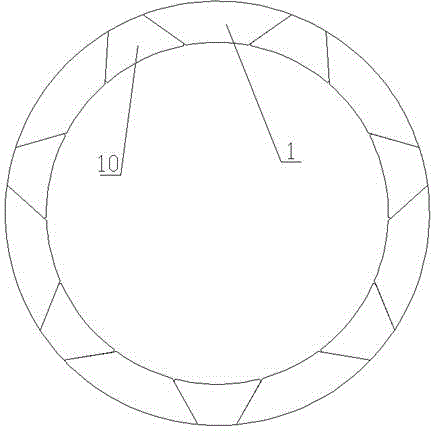

[0016] exist figure 1 , figure 2 , image 3 , Figure 4 Among them, the present invention includes a telescopic mechanism and a transmission mechanism, wherein the telescopic mechanism is mainly composed of a narrow drum tile telescopic mechanism and a wide drum tile telescopic mechanism. The narrow drum tile telescopic mechanism includes: narrow drum tile 10, narrow drum tile bracket 9; the wide drum tile telescopic mechanism includes: wide drum tile 1, wide drum tile bracket 18. The transmission mechanism includes: piston rod 14, end cover 6, clamp ring 4, base 13, limit plate 15, narrow tile lateral slider 8, narrow tile lateral guide rail 7, wide tile lateral slider 2, wide tile Side guide rail 3, wide tile bottom slide block 16, wide tile bottom guide rail 17, narrow tile bottom slide block 12, narrow tile bottom guide rail 11. The end cover 6 is fixed to one end of the base 13, and is fixedly connected to the piston rod 14 through the clamp ring 4 and the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com