Spiral dust collection drilling machine

A drilling machine and vacuum mechanism technology, which is applied to portable drilling machines, drilling/drilling equipment, metal processing machinery parts, etc., can solve the problems of difficult adjustment of drilling depth, dust pollutes the environment, and damages human health. Beneficial to human health and the effect of reducing dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

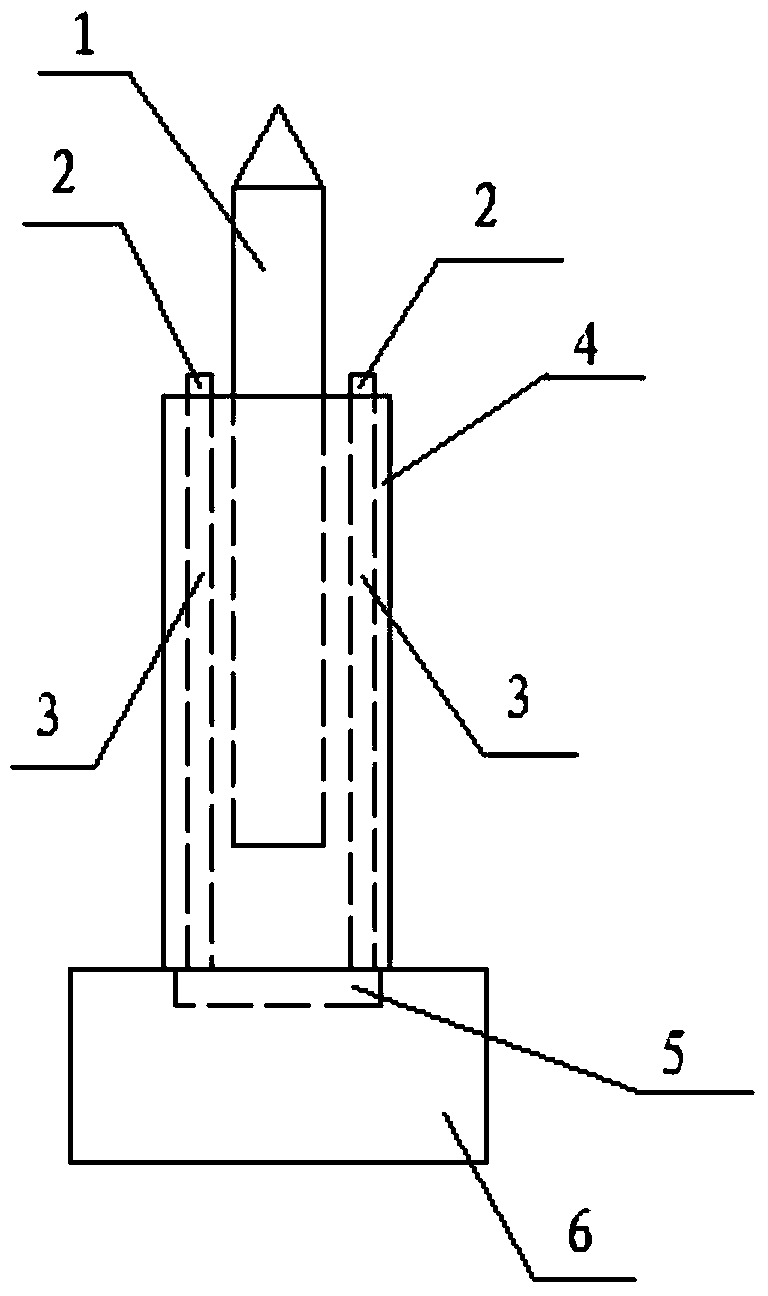

[0012] like figure 1 As shown, the spiral vacuum drilling machine of the present invention includes a power mechanism 6, a rotary mechanism 4, a drill bit 1, a dust suction mechanism 2, and a dust suction pipeline 3. The rotary mechanism 4 is movably connected with the power mechanism 6, and the power mechanism 6 drives the rotary mechanism 4. Rotate, the top of the rotating mechanism 4 is fixedly installed with a dust collection mechanism 2, the dust collection mechanism 2 is fixedly connected with the dust suction pipe 3, and the dust suction pipe 3 passes through the inside of the rotation mechanism 4 and communicates with the dust collection box 5 fixedly installed in the power structure 6 The dust collecting bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com