Production equipment for high-quality asphalt mixture and production method thereof

A technology for asphalt mixture and production equipment, applied in the direction of roads, road repair, roads, etc., can solve the problems of unrealizable, fine aggregate can not be subdivided in the next step, etc., to improve the grade, meet the high quality, and reduce the loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below through specific embodiments.

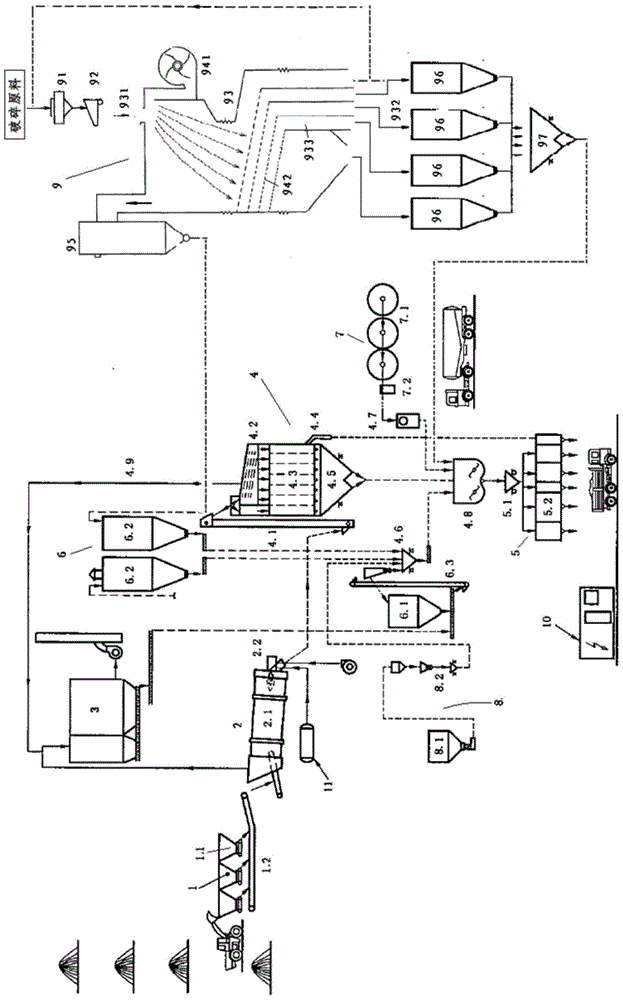

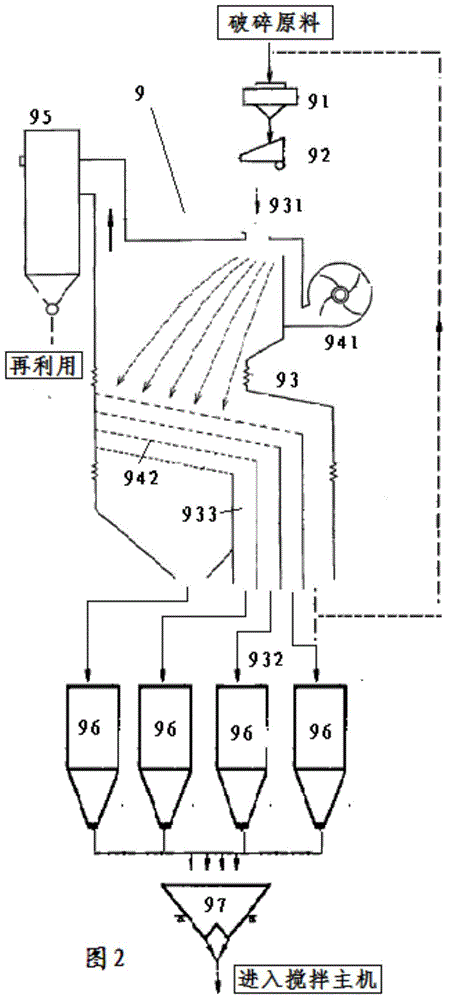

[0030] refer to Figure 1 to Figure 2 As shown, high-quality asphalt mixture production equipment includes aggregate supply system 1, drying heating system 2, negative pressure dust removal system 3, intermittent asphalt mixture mixing system 4, finished material storage system 5, and powder supply System 6, asphalt storage system 7, special component addition system 8, fine aggregate processing system 9 and operating room 10;

[0031] The aggregate supply system 1 includes a multi-stage aggregate bin 1.1 and a conveyor belt 1.2. The aggregate in the aggregate bin 1.1 is sent to the drying heating system 2 through the conveyor belt 1.2, which can realize the storage, distribution, and measurement;

[0032] The drying heating system 2 includes a drying drum 2.1 and a burner 2.2, through which the aggregate in the drying drum 2.1 can be dried and heated at a set temperature;

[0033] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com