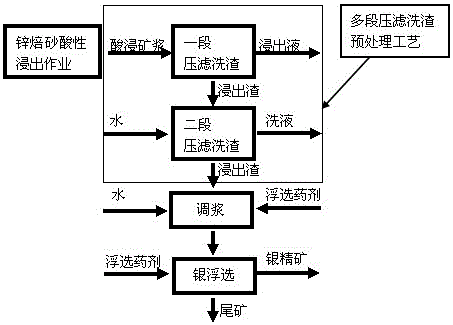

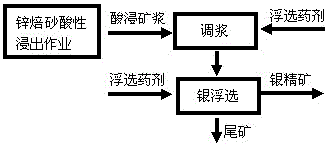

A production process for flotation of silver with hydrometallurgy zinc acid leaching pulp

A technology for hydrometallurgical zinc smelting and production process, which is applied in flotation, solid separation and other directions to achieve the effects of saving equipment and infrastructure investment, reducing organic content and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

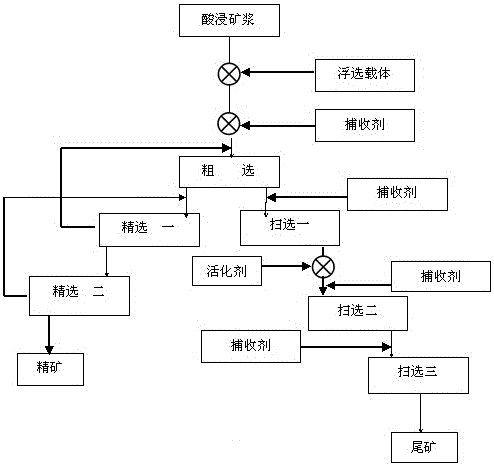

[0057] A zinc-acid leaching ore pulp in a hydro-smelting process that has not been filtered and washed has a pulp concentration of 30%, a zinc ion concentration of 185g / l, a pulp pH of 2.6, a pulp temperature of 70°C, and a silver content of 466 g / ton. Get 2500 milliliters of this ore pulp respectively, move in 3 liters of single tank flotation machines, according to image 3 As shown in the technological process, the flotation carrier with an amount of 5 kg / ton of calcined sand is added to the roughing slurry tank, the activator of 40 grams / ton of calcined sand is added to the stirring tank of Sweep 2, and the collector of 120 grams / ton of calcined sand is added to the rough selection. Ton calcine, add collector 60 g / ton calcine in sweep 1 and sweep 2 respectively, add collector 30 g / t calcine in sweep 3, the results of closed-circuit flotation test are shown in Table 1.

[0058]

example 2

[0060] A zinc-acid leaching ore pulp in a hydro-smelting process that has not been filtered and washed has a pulp concentration of 31%, a zinc ion concentration of 193g / l, a pulp pH of 2.8, a pulp temperature of 69°C, and a silver content of 397 g / ton. Get 2500 milliliters of this ore pulp respectively, move in 3 liters of single tank flotation machines, according to image 3 As shown in the technological process, the flotation carrier with an amount of 4 kg / ton of calcined sand is added to the roughing slurry tank, the activator of 35 grams / ton of calcined sand is added to the stirring tank of Sweep 2, and the collector of 100 grams / ton of calcined sand is added to the rough selection. Ton calcine, add collector 50 g / ton calcine in sweep 1 and sweep 2 respectively, add collector 25 g / t calcine in sweep 3, the results of closed-circuit flotation test are shown in Table 2.

[0061]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com