Large power ceramic heating unit

A ceramic heating element and high-power technology, applied in the direction of heating element materials, etc., can solve the problems of increased power requirements and high power, and achieve the effects of reducing power density, reducing temperature difference, and preventing fracture damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

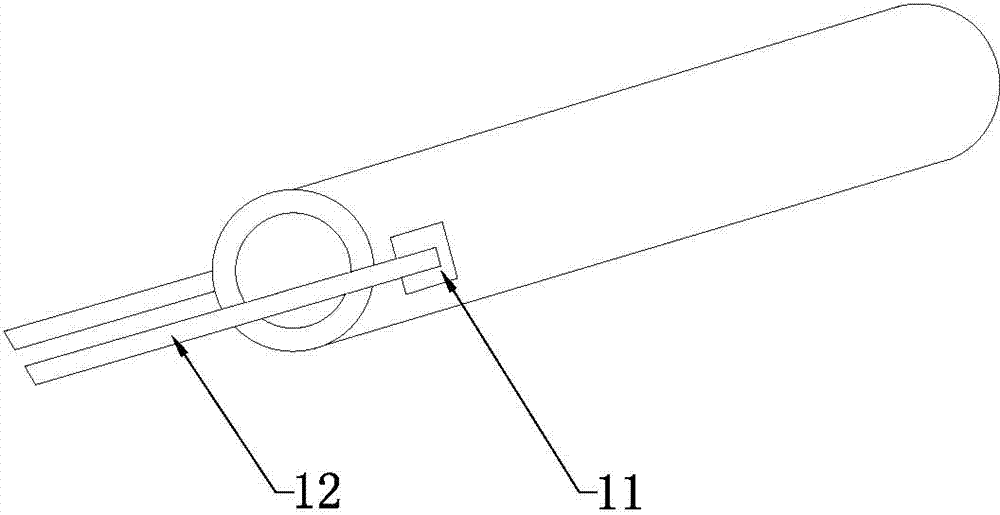

[0025] Such as Figure 1 to Figure 4 As shown, a high-power ceramic heating element of the present invention includes an alumina ceramic core 1 and an alumina substrate 2, and a thick-film heating circuit 21 is printed on the inner surface of the alumina substrate 2, and the thick-film heating The circuit 21 is in a reciprocating and folding structure, and a distance H is formed between the thick film heating circuits 21 in a reciprocating and folding structure. The alumina substrate 2 is wrapped on the outer surface of the alumina ceramic core 1 in a roll shape. The line width L of the thick film heating circuit 21 is 0.3-1.3 mm, and the ratio H / L of the spacing H formed by the thick film heating circuit 21 to the line width L of the thick film heating circuit 21 is 0.5-1.5; the aluminum oxide The thickness T of the substrate 2 is 0.3-0.8 mm, and the ratio W / T of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com