Portable calibration device for parking braking performance tester

A calibration device, portable technology, applied in the direction of measuring device, force/torque/work measuring instrument calibration/test, instrument, etc., can solve the problems of harsh working environment, unfavorable tool operation, small working space, etc., to achieve a clean operating environment , Enhance safety and aesthetics, reduce the effect of volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

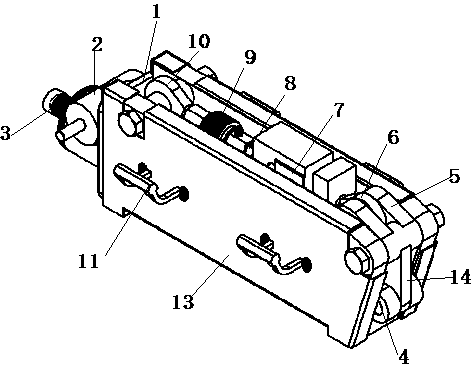

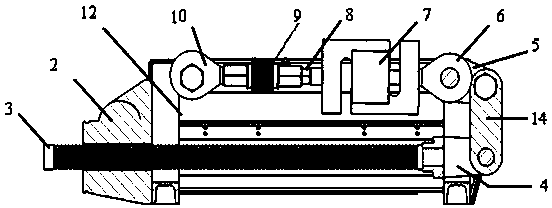

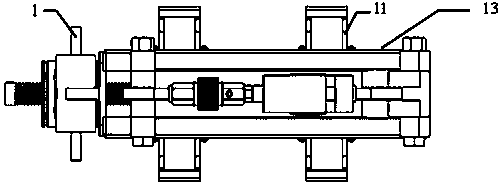

[0020] Such as Figure 1 to Figure 4 As shown, the portable parking brake performance tester calibration device of the present invention is composed of a force applying system, a force receiving system and an auxiliary structure.

[0021] The force application system includes a force application end 1 , a worm gear booster 2 , a force application screw 3 , and a force application link 4 .

[0022] The force bearing system includes a force bearing link joint 5 , a force bearing end movable joint 6 , a standard sensor 7 , a sensor double thread connector 8 , and a fixed end movable joint 10 .

[0023] The auxiliary structure includes a carrying handle 11 , a partition 12 , a housing 13 , and a lever 14 .

[0024] The force application end 1 is equipped with a worm gear booster 2, the worm gear in the worm gear booster 2 is engaged with the force screw 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com