Low-temperature high-resistance temperature coefficient non-heat stagnation thin-film material and preparation method thereof

A thin film material, temperature coefficient technology, applied in metal material coating process, vacuum evaporation coating, coating and other directions, can solve the problems of rare reports of vanadium trioxide thin film resistance temperature coefficient, achieve good thermal characteristics, eliminate Thermal hysteresis loop, effect of high temperature coefficient of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The substrate is plated with a layer of SiN x The Si sheet is used as the substrate, and the SiNx layer is mainly an insulating layer to avoid the leakage of the film in the electrical test, and is cleaned by standard ultrasonic cleaning with acetone, ethanol and deionized water. Using a multifunctional magnetron sputtering system, high-purity metal vanadium (purity: 99.99%), metal Ti (purity: 99.99%), and metal W (purity: 99.99%) are used as targets. The target diameter is 2 inches and the thickness is 5mm. , the background vacuum is 3×10 -5 Pa, the deposition temperature is 300-500°C, the Ar gas flow rate is 40 sccm, the sputtering power is 60w, 5w, 5w respectively, the sputtering time is 150min, and the oxygen flow rate is 0.4sccm (that is, the oxygen partial pressure is 1.0 %).

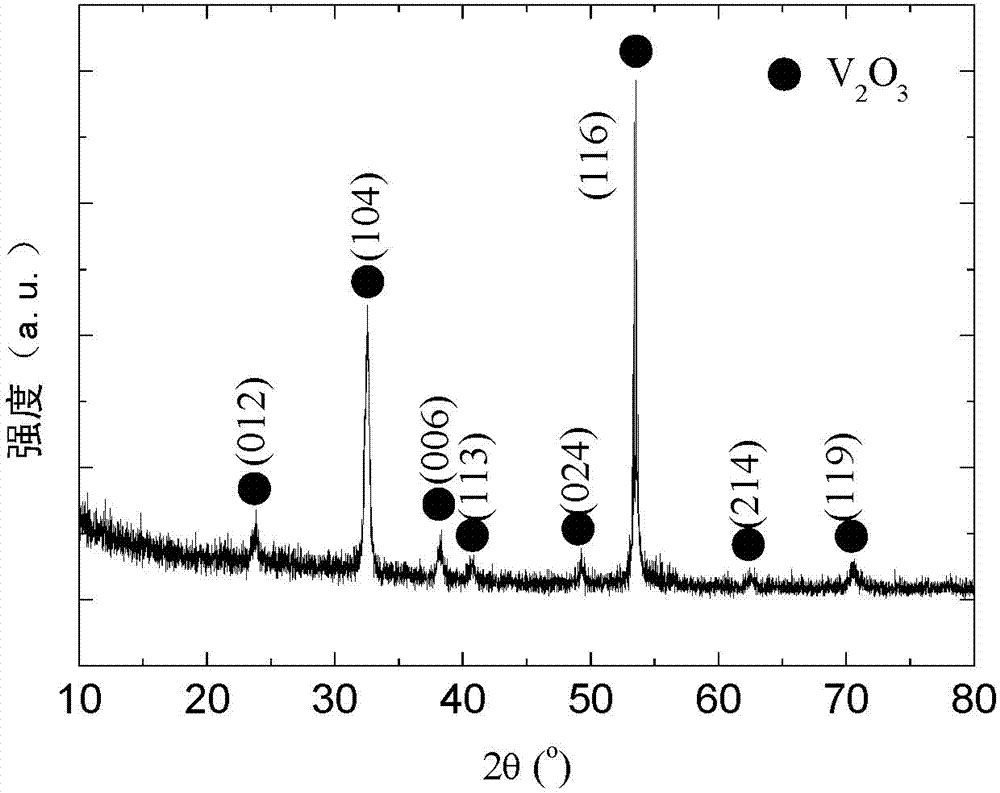

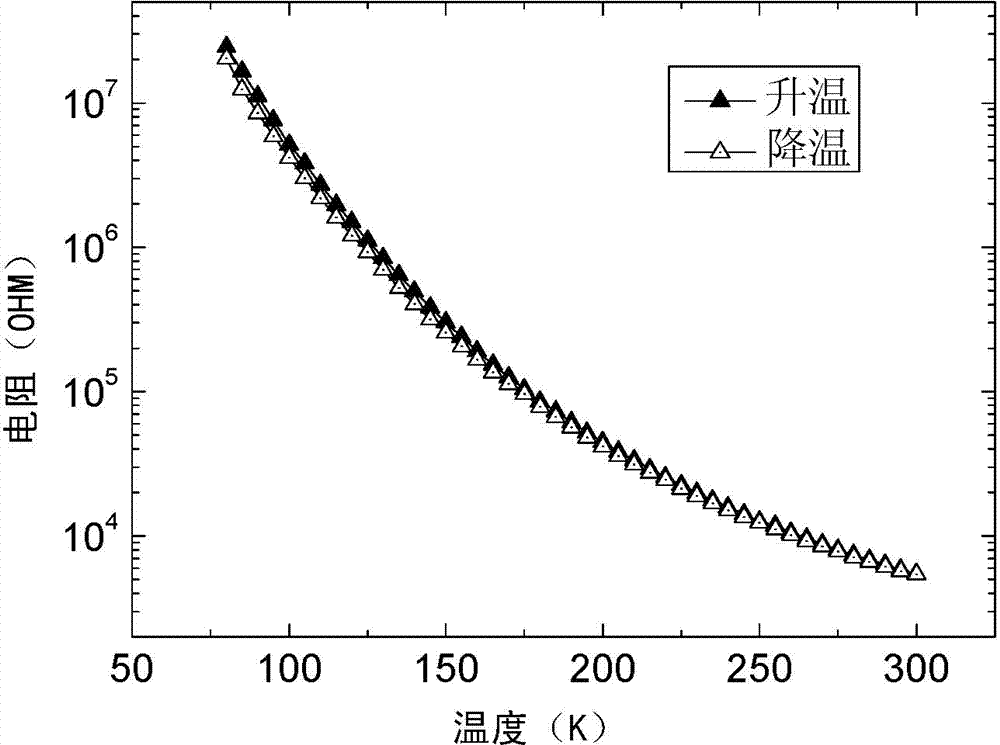

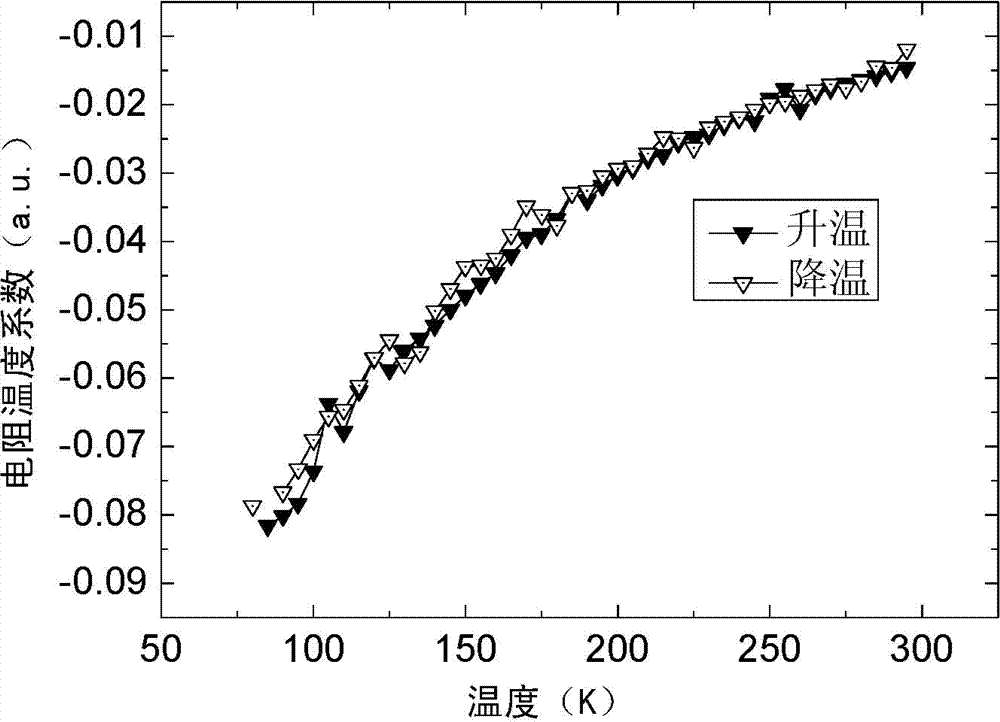

[0045] X-ray diffractometer analysis (XRD) was used to test the crystalline phase of the film as figure 1 As shown, the film exhibits V 2 o 3 Pure crystalline phase, no impurity phase ...

Embodiment 2

[0047] The steps of Example 1 were basically repeated, except that the sputtering powers of V, Ti, and W were 80W, 8W, and 10W, respectively, and the oxygen flow rate was 0.48 sccm, that is, the oxygen partial pressure was 1.2%. X-ray diffractometer analysis (XRD) test shows that the prepared film presents V 2 o 3 Pure crystalline phase, no impurity phase formation. From heating up to cooling down, the resistance temperature curve has no thermal hysteresis and no sudden change. In the low temperature range (80K-225K), it has a high temperature coefficient of resistance (-3% / K~-8% / K).

Embodiment 3

[0049] The steps of Example 1 were basically repeated, except that the sputtering powers of V, Ti, and W were 100 W, 10 W, and 15 W, respectively, and the oxygen flow rate was 0.6 sccm, that is, the oxygen partial pressure was 1.5%. X-ray diffractometer analysis (XRD) test shows that the prepared film presents V 2 o 3 Pure crystalline phase, no impurity phase formation. From heating up to cooling down, the resistance temperature curve has no thermal hysteresis and no sudden change. In the low temperature range (80K-225K), it has a high temperature coefficient of resistance (-3% / K~-8% / K).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com