Substrate transportation equipment and transportation method

A technology of transportation equipment and transportation methods, applied in transportation and packaging, conveyor objects, electrical components, etc., can solve problems such as increasing overall operating costs and increasing cycle time, reducing handling volume, reducing production cycle time, and providing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

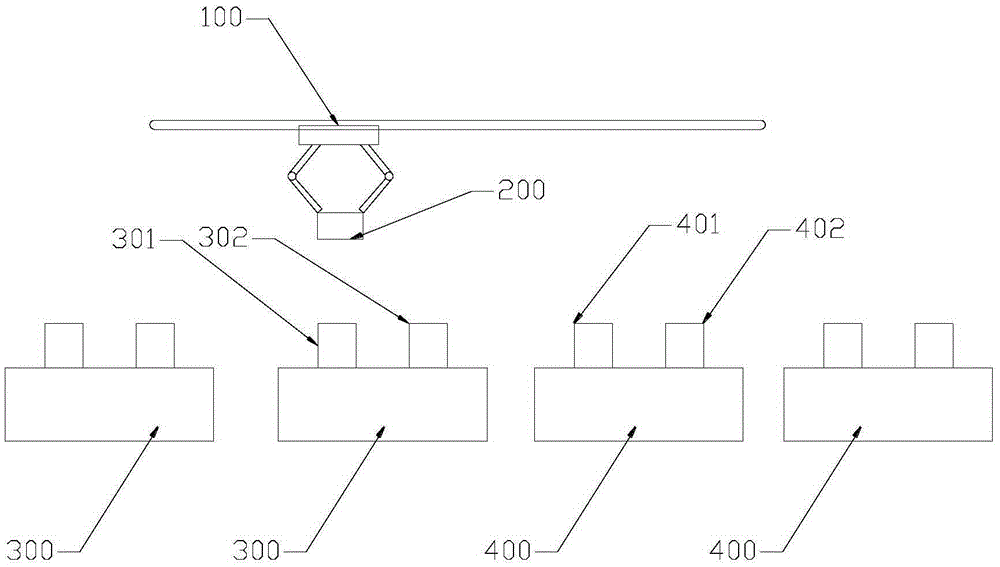

[0028] In order to overcome such as figure 1 In the prior art, the handling machine 100 needs to carry the cassette 200 multiple times during the substrate production process. The present invention improves the original way of setting the processing chambers in parallel, so that the number of times the cassette 200 is transported by the transporter 100 is minimized during the transport process.

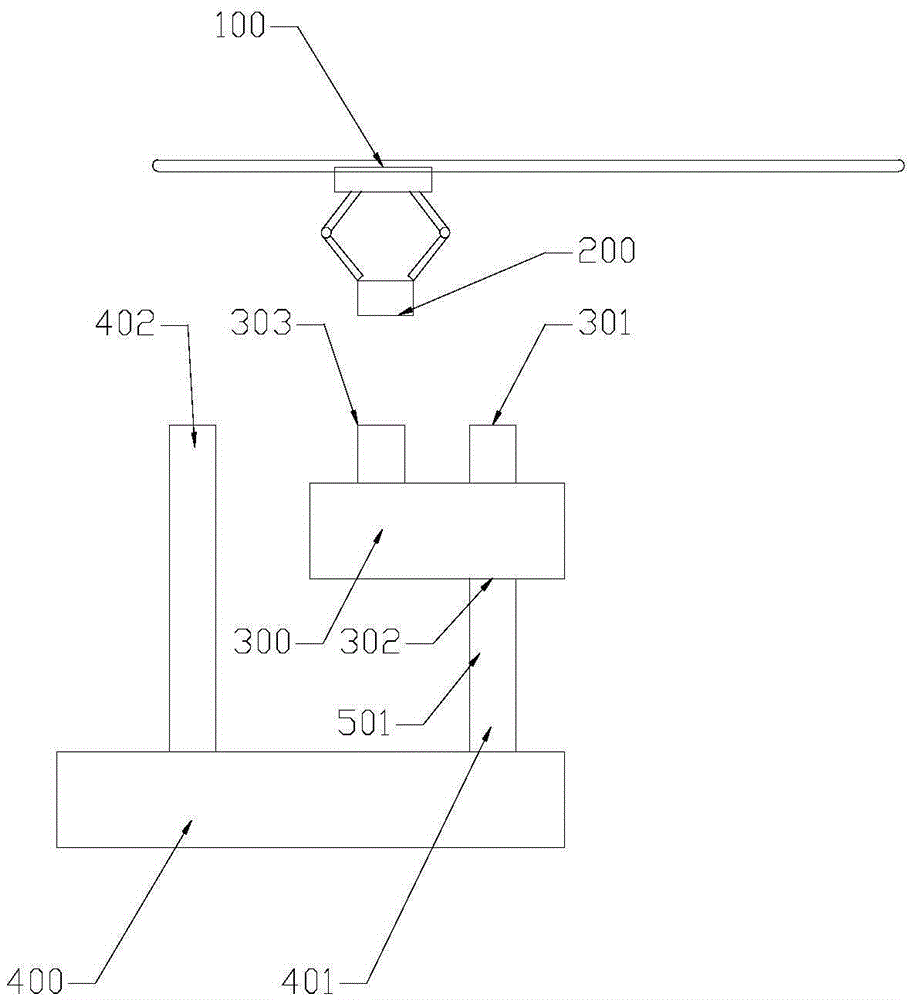

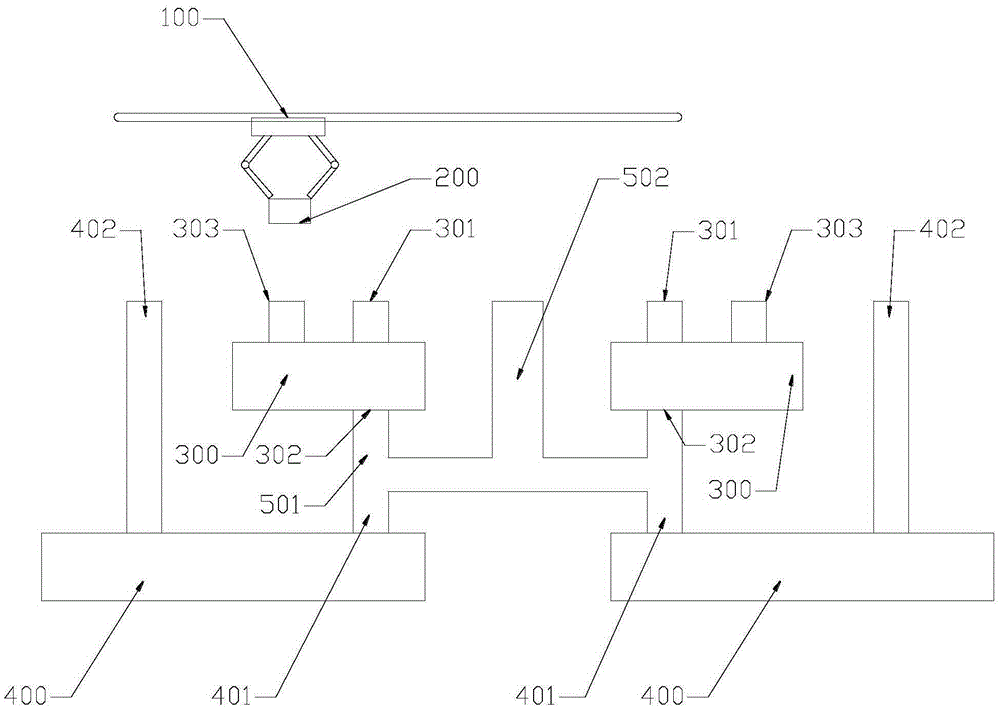

[0029] Such as figure 2 Shown is a schematic structural view of the first embodiment of the substrate transportation equipment of the present invention. In this embodiment, the original processing chambers arranged in parallel are changed to a mixed series form, that is, the first processing chamber 300 and the second processing chamber 400 are opposite to each other. The moving direction of the conveyor 100 is vertically arranged, the first proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com