Large torque and super-large torque test system for engineering equipment

A technology for engineering equipment and torque testing, applied in measuring devices, torque measurement, power measurement, etc., can solve the problems of inability to calculate the maximum value of static torque, large cumulative error, design and development products factory debugging and product application problems, etc. To achieve the effect of convenient axial assembly and disassembly, small error, and interference prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

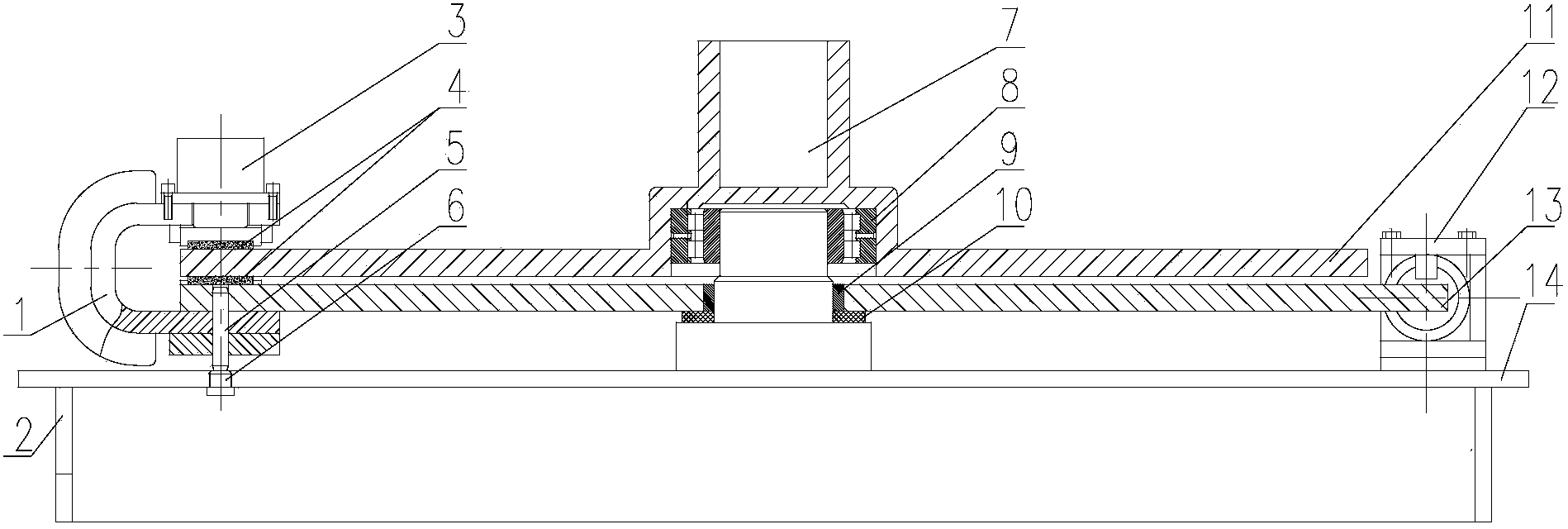

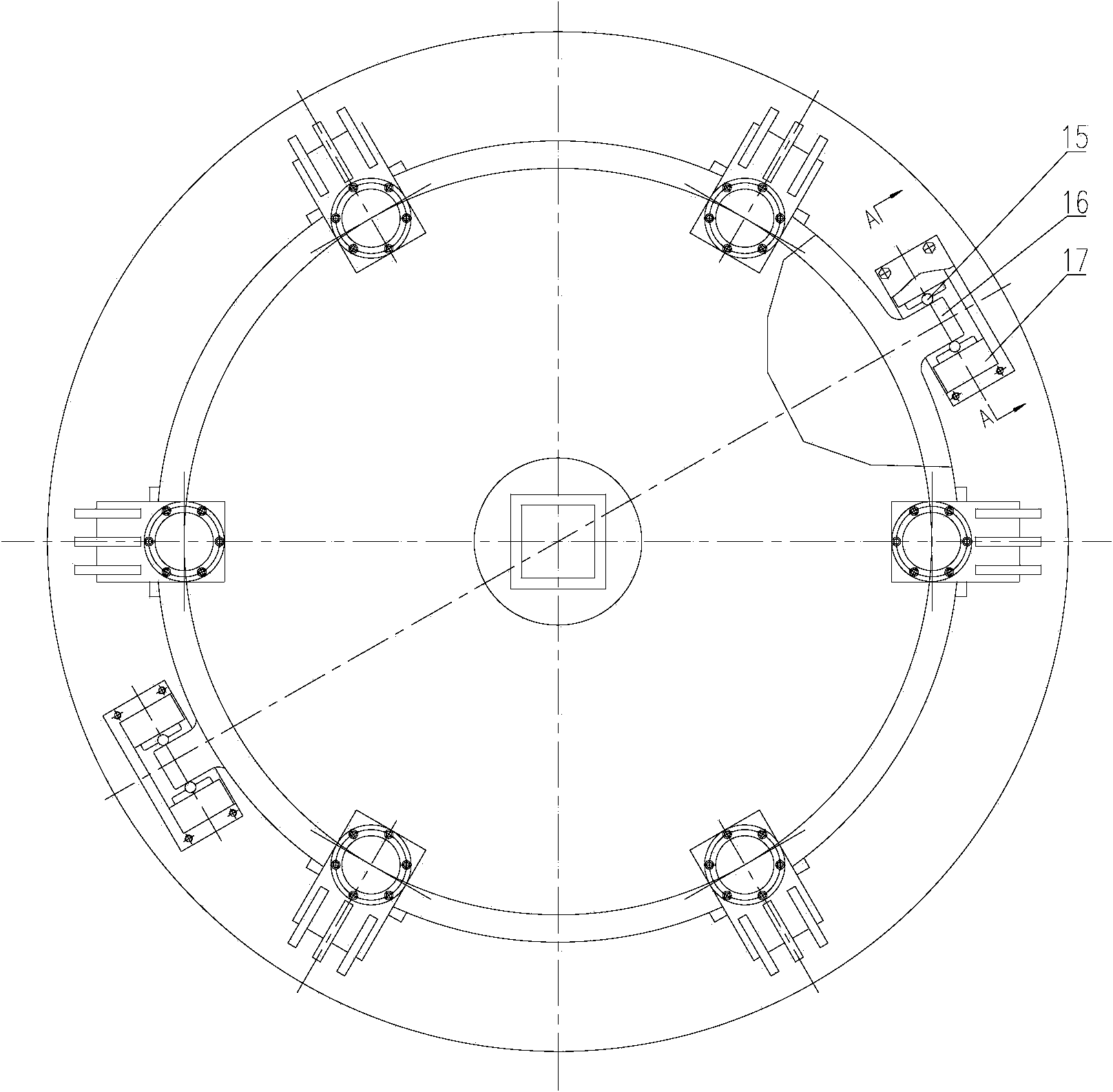

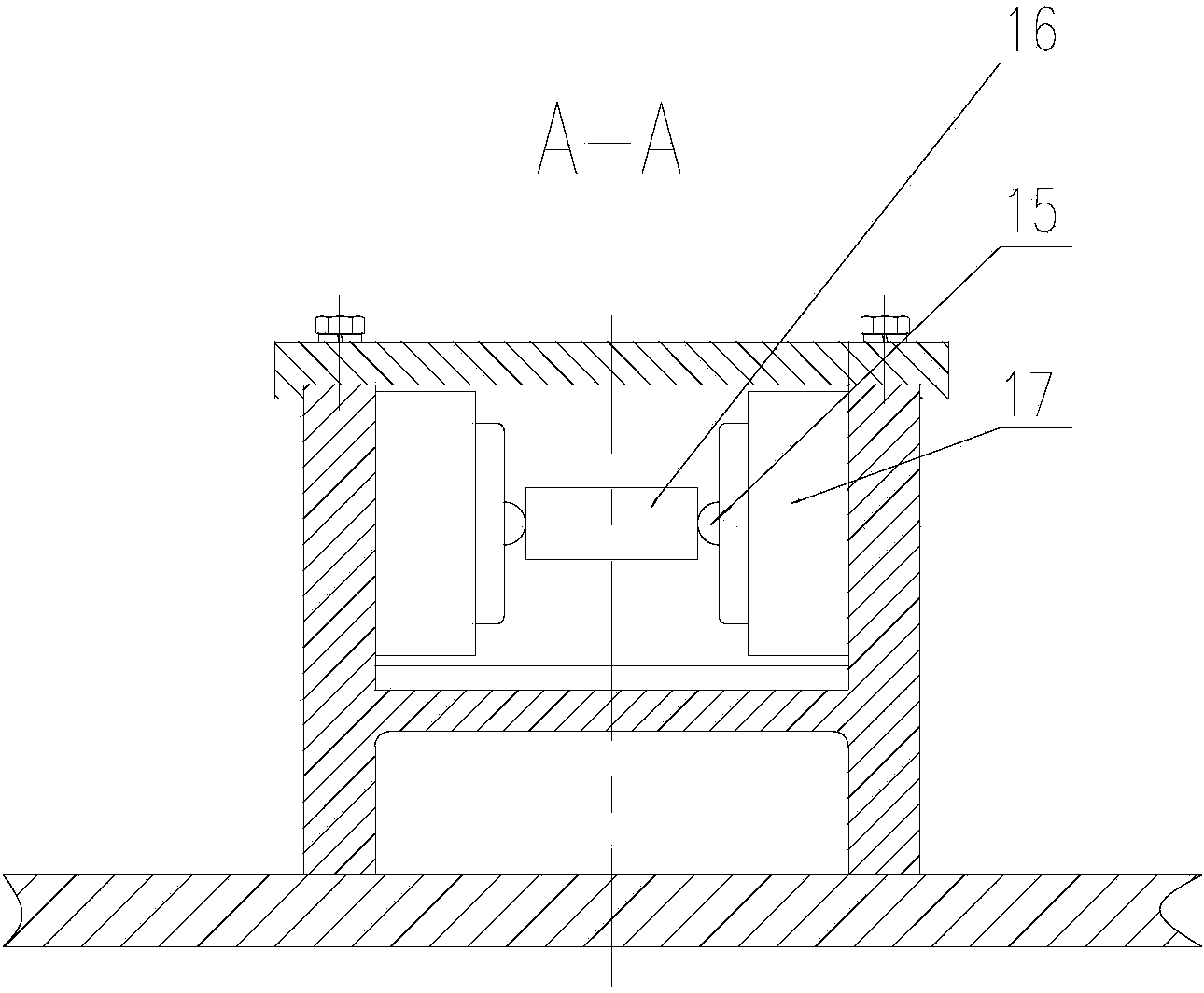

[0022] Below in conjunction with accompanying drawing, the specific implementation manner of this patent is described in further detail.

[0023] Such as figure 1 , 2 , 3, a large torque and super torque test system for engineering equipment, including C-shaped bracket 1, stop pin removal window 2, pressurized plunger cylinder 3, friction plate 4 (the friction plate in this example includes upper friction plate and Lower friction plate), stop pin 5, hexagon socket plug 6, drill bit matching square hole 7, double row cylindrical roller bearing without inner ring rib 8, bearing 9, bearing ring 10, friction disc 11, pressure plate 12, measuring Force plate 13, base plate 14, fixed-point force transmission ball 15, force measuring plate extension end 16, force measuring plunger cylinder 17, and the fixing part fixed on the friction plate 11 is a drill bit matched with a square hole 7, which is convenient to connect with the drill pipe , the force measuring disc 13 and the fricti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com