On-line real-time detection system for fiber optic pantograph carbon slide wear

A pantograph carbon slide, real-time detection technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of inability to effectively carry out ultrasonic or photographic camera measurement, incapable of dynamic monitoring of train pantograph slides, etc., to achieve convenient Online real-time measurement, wide range of use, reliable monitoring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

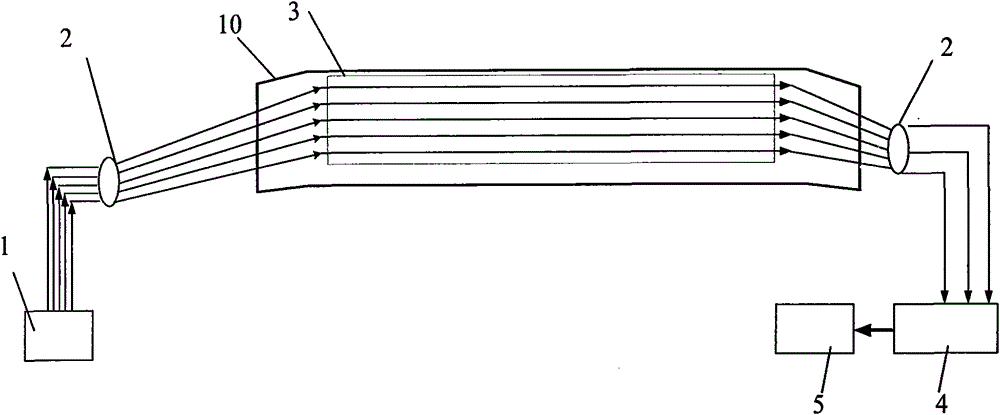

[0035] like figure 1 As shown, the fiber-optic pantograph carbon slide wear online real-time detection system in this embodiment includes a light source [1], a multi-core optical fiber plug [2], a fiber-optic wear sensor [3], a photocoupler [4], a signal Processing unit [5].

[0036] The multi-core optical fiber plug [2] is used for the connection of each discrete optical device, preferably a pluggable cluster ring made of ceramics.

[0037] The optical fiber wear sensor [3] adopts the transmissive layout method, the light source [1] emits light beams, passes through the optical fiber wear sensor [3], and transmits into the photoelectric coupler [4] to form a complete transmissive optical path. The signal processing unit [5] is connected with the optocoupler [4] through a shielded cable. The fiber optic wear sensor [3] is fixed on the side of the pantograph carbon slide [10] by gluing. The pantograph carbon slide [10] has a side width of 15 mm and a length of 1000 mm. The b...

Embodiment 2

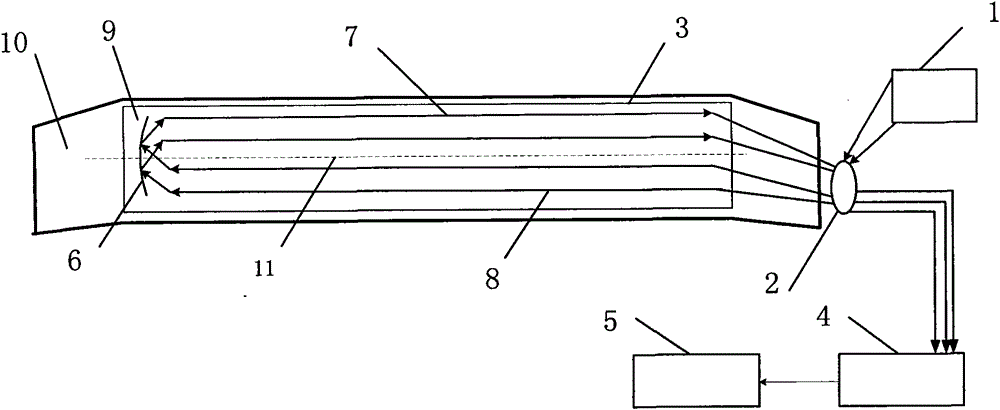

[0042] like figure 2 As shown, the fiber-optic pantograph carbon slide wear online real-time detection system in this embodiment includes a light source [1], a multi-core optical fiber plug [2], a fiber-optic wear sensor [3], a photocoupler [4], a signal Processing unit [5].

[0043] The multi-core optical fiber plug [2] is used for the connection of each discrete optical device, preferably a pluggable cluster ring made of ceramics.

[0044] The fiber optic wear sensor [3] adopts the reflective layout method, the light source [1] emits a beam, the beam passes through the fiber optic wear sensor [3], and is reflected by the light return body [6] into the photoelectricity at the other end of the fiber optic wear sensor [3]. The coupler [4] forms a complete reflection optical path. The signal processing unit [5] is connected with the optocoupler [4] through a shielded cable. The pantograph carbon slide [10] has a side width of 15 mm and a length of 1000 mm. The optical fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com