Flat-plate heat exchanger filled with metal foam at partial portion

A technology of filling metal and metal foam sheets, which is applied in the direction of regenerative heat exchangers, heat exchanger types, indirect heat exchangers, etc., can solve the problems of large pressure drop and low heat exchange performance in heat exchange channels, and achieve high Effect of specific surface area and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

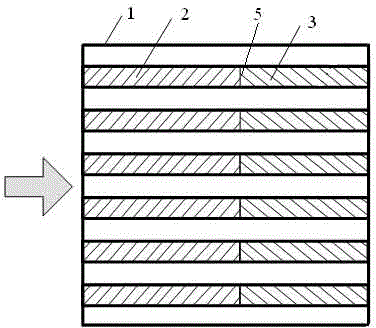

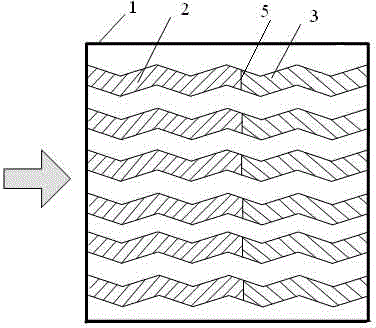

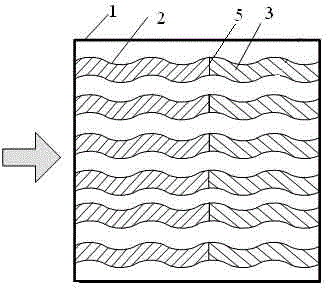

[0017] Specific implementation mode one: see Figure 1 to Figure 4 , a flat plate heat exchanger partially filled with metal foam in this embodiment includes a heat exchanger channel 1, and the flat heat exchanger also includes a plurality of metal foam sheets 5, and the plurality of metal foam sheets 5 are arranged from top to bottom Equidistantly arranged horizontally in the heat exchanger channel 1, each metal foam sheet 5 is composed of a front metal foam sheet 2 and a rear metal foam sheet 3, and the front metal foam sheet 2 and the rear metal foam sheet 3 are arranged along the heat exchange The flow direction of the medium is arranged sequentially, the porosity of the metal foam sheet 2 in the front section is between 0.65 and 0.85, and the pore density is between 50PPI and 150PPI (PPI is the number of cells on the unit inch length), and the metal foam sheet in the back section is The porosity of the foam sheet 3 is between 0.85 and 0.99, and the pore density is between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com