Method and drilling tool for directional-blasting well drilling

A technology of directional blasting and drilling, which is applied in the field of natural gas exploitation and petroleum, which can solve the problems of increasing drilling cost, affecting oil and gas circulation, increasing oil and gas flow resistance, etc., and achieves the effects of reducing the incidence of drilling accidents, simple and convenient operation, and accelerating drilling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

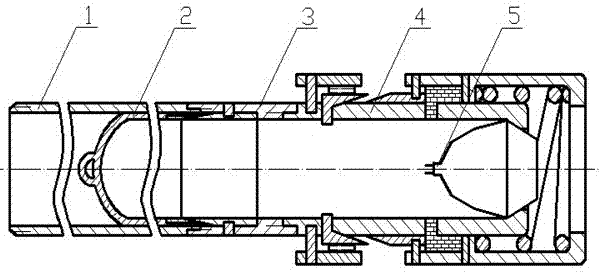

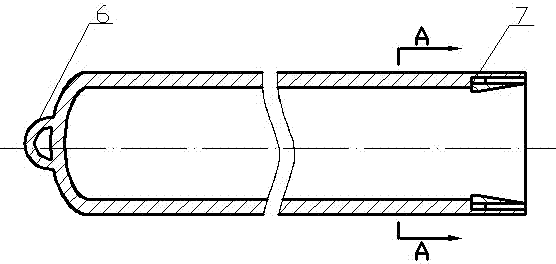

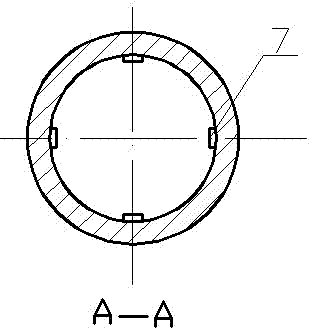

[0017] The present invention will be further described below in conjunction with accompanying drawing:

[0018] The present invention relates to a method for directional blasting drilling. The method is as follows: the rock is melted and extruded by the high-energy jet generated by the explosion of the perforating charge 5 to form a large perforation similar to that formed by explosive blasting, and the melted rock will It will be compacted and then cooled to form a layer of solid rock formation, which can achieve the purpose of well cementing; then through the mechanism, the perforating charges 5 can be exploded intermittently one by one at a suitable position in the perforation, and the hole depth will be continuously increased. Large, so as to achieve the purpose of circular directional blast drilling.

[0019] as attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a drilling tool for directional blasting drilling in the present invention mainly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com