A kind of preparation method of composite thermal insulation and energy saving lightweight concrete wall panel

A lightweight concrete, composite thermal insulation technology, applied in building materials and other directions, can solve problems such as unfavorable environmental protection and energy saving, unfavorable transportation and construction, poor durability, etc., and achieve good development prospects, good building energy-saving effects, and good hanging performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

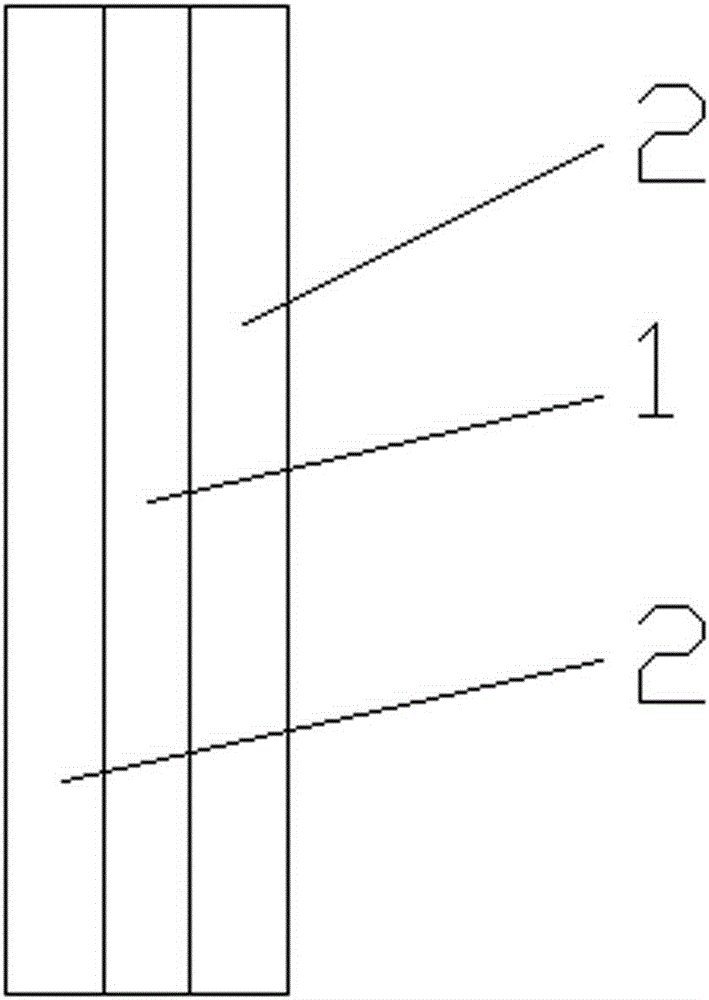

[0017] A preparation method of composite thermal insulation and energy-saving lightweight concrete wallboard, comprising an aerated concrete core plate 1, and wallboard composite surface layers 2 are bonded on the two largest surfaces of the aerated concrete core plate 1; and the preparation method thereof as follows:

[0018] The first step is to prepare the slurry: take sand 40-60, lime 12-17, cement 15-20, gypsum 2-3, aluminum powder 0.08, water-to-battery ratio 0.6-0.65 according to the composition and weight ratio, and combine the above materials Put it into the mixer and stir evenly for 4-6 minutes to make slurry;

[0019] The second step is to prepare the steel frame: select cold-drawn low carbon steel wire of φ3~φ4 mm, and process it into a steel frame smaller than the size of the aerated concrete core plate through an automatic welding machine;

[0020] The third step is to prepare the aerated concrete core plate: fix the prepared steel frame in the aerated concrete core pl...

Embodiment 1

[0025] Example 1: Take sand 40-60, lime 12-17, cement 15-20, gypsum 2-3, aluminum powder 0.08, water-to-material ratio 0.6-0.65 according to the composition and weight ratio, and put the above materials into the mixer Stir uniformly for 4 to 6 minutes to prepare slurry. Select cold drawn low carbon steel wire of φ3 to φ4 mm, and process it into a reinforcing steel skeleton smaller than the size of the aerated concrete core plate through an automatic welding mesh machine, and then combine the prepared steel skeleton It is fixed in the aerated concrete core plate mold, and the slurry is injected into the aerated concrete core plate mold, and the aerated concrete core plate mold is placed in a pre-curing kiln with a temperature of 40-60℃ and left for 60-90 minutes. After that, the aerated concrete core slab mold is sent to the autoclave for steam curing, and the aerated concrete core slab is prepared by steaming for 8-10 hours under the condition of air pressure of 1.6 mpa and temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com