Clostridium sporogenes and purpose thereof

A Clostridium sporogenes, the use of technology, applied in the field of Clostridium sporogenes, to achieve great application and promotion value, the effect of improving the rate of superior products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 strain screening

[0026] 1 strain screening

[0027] 1.1 Primary screening of strains

[0028] 1.1.1 Material: Jiannanchun old cellar mud

[0029] 1.1.2 Medium:

[0030] Sodium acetate 8g, MgC 2 200mg,NH 4 Cl500mg, MnSO 4 2.5mg, CaSO 4 10mg, FeSO 4 5mg, sodium molybdate 2.5mg, biotin 5ug, p-aminobenzoic acid 100ug, distilled water 1000mL, natural pH, sterilize at 121°C for 20min, after cooling, add ethanol 25mL aseptically.

[0031] The medium is sterilized at 121°C for 20 minutes; culture temperature: 35-37°C, culture condition: anaerobic culture.

[0032] 1.1.3 Experimental method

[0033] Under aseptic conditions, take 10 grams of Jiannanchun Laojiao Mud in a 250mL triangular flask filled with 90mL of sterile water and glass beads, place it on a bed and shake it at room temperature for 30 minutes. Treat it in an 80-degree water bath for 10 minutes, take the bacterial solution and dilute it to 10 times in a 10-fold gradient -6 , take 1mL of the b...

Embodiment 2

[0034] Caproic acid production condition optimization experiment of the bacterial strain of embodiment 2

[0035] 1.1 Optimization of fermentation conditions for caproic acid production by strains

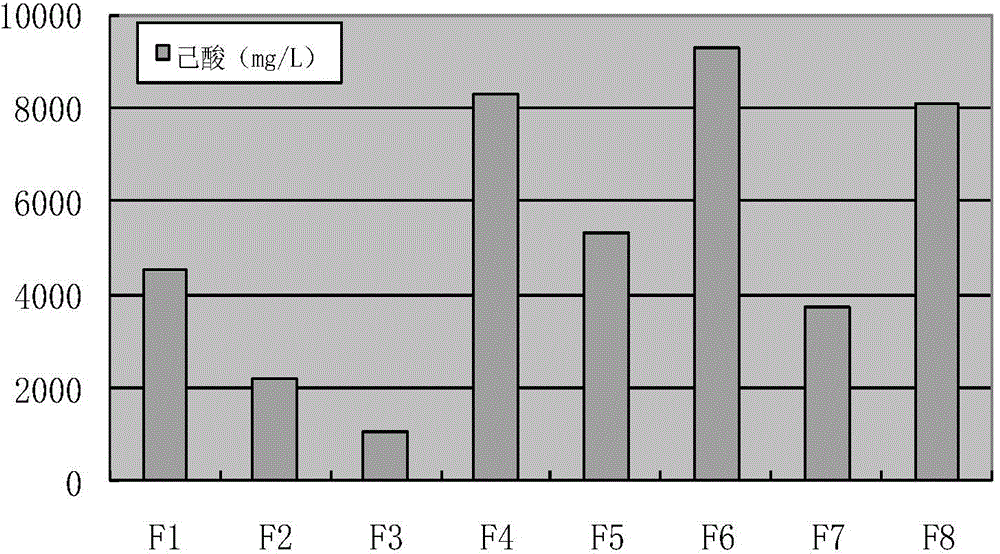

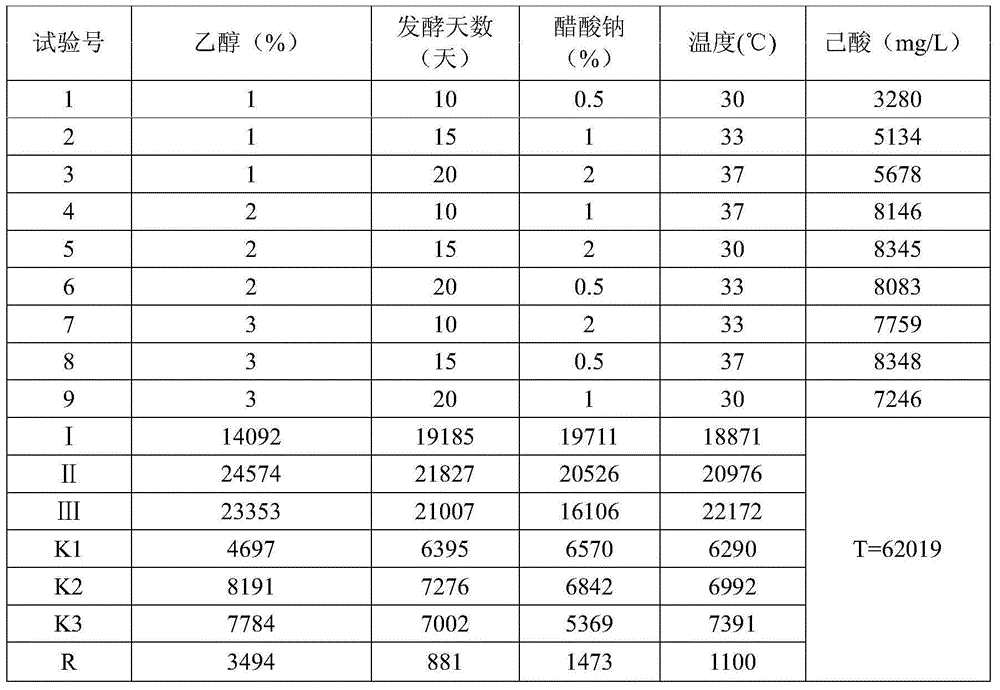

[0036] Select temperature, fermentation days, sodium acetate and ethanol concentration as four factors and three levels to design an orthogonal experiment, and the experimental results are shown in Table 1.

[0037] Orthogonal experiment results showed that the concentration of ethanol had a greater effect on caproic acid production, followed by the concentration of sodium acetate, and the effect of temperature and fermentation time was relatively small. The optimum conditions for caproic acid production are: temperature 37°C, incubation time 15 days, ethanol concentration 2%, sodium acetate concentration 1%.

[0038] The caproic acid production test was carried out on 8 single strains metabolizing caproic acid using the optimized fermentation culture conditions. The caproic acid ...

Embodiment 3

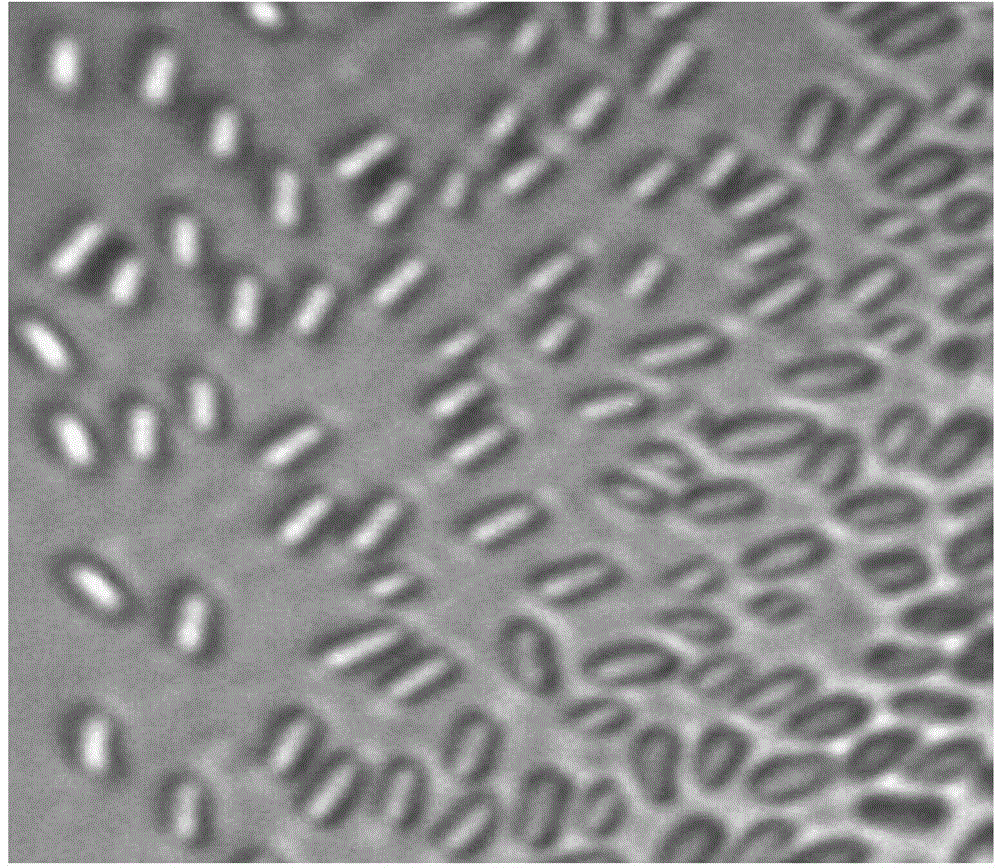

[0042] The identification of embodiment 3 bacterial strains

[0043] 16SrDNA Sequence Analysis Method of 1F6 Strain

[0044] 1.1 DNA extraction

[0045] The cells were collected by centrifugation and dissolved in 5 mL of extraction buffer (100 mM Tris Cl, 100 mM EDTA-Na 2 , 200mM NaCl, 2%CTAB, pH8.0), shake at 37°C for 45min. Add 0.75mL20%SDS, 65 ℃ water bath for 1h. Centrifuge at 12,000rpm for 10min and collect the supernatant. The supernatant was extracted twice with an equal volume of phenol: chloroform: isoamyl alcohol (25:24:1), added with a final concentration of 0.3M NaAC (pH 5.2) and 2 times the volume of absolute ethanol, and precipitated at room temperature for 1 h. Centrifuge at 12,000 rpm at 4°C for 20 min to collect the precipitate, rinse twice with 70% ethanol, dry and dissolve in 50 μL TE.

[0046] 1.2PCR amplification

[0047]Using total DNA as a template, bacterial universal primers EU27F (AGAGTTTGATCCTGGCTCAG) and 1492R (GGTTACCTTGTTACGACTT) were used a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com