Novel cellar sealing device and application thereof

A new type of cellar technology, applied in wine cellar appliances, biochemical equipment and methods, etc., can solve problems such as poor wine quality, low efficiency, and strong smell of sealing mud, so as to increase the content of ethyl hexanoate and improve production The effect of improving the quality and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

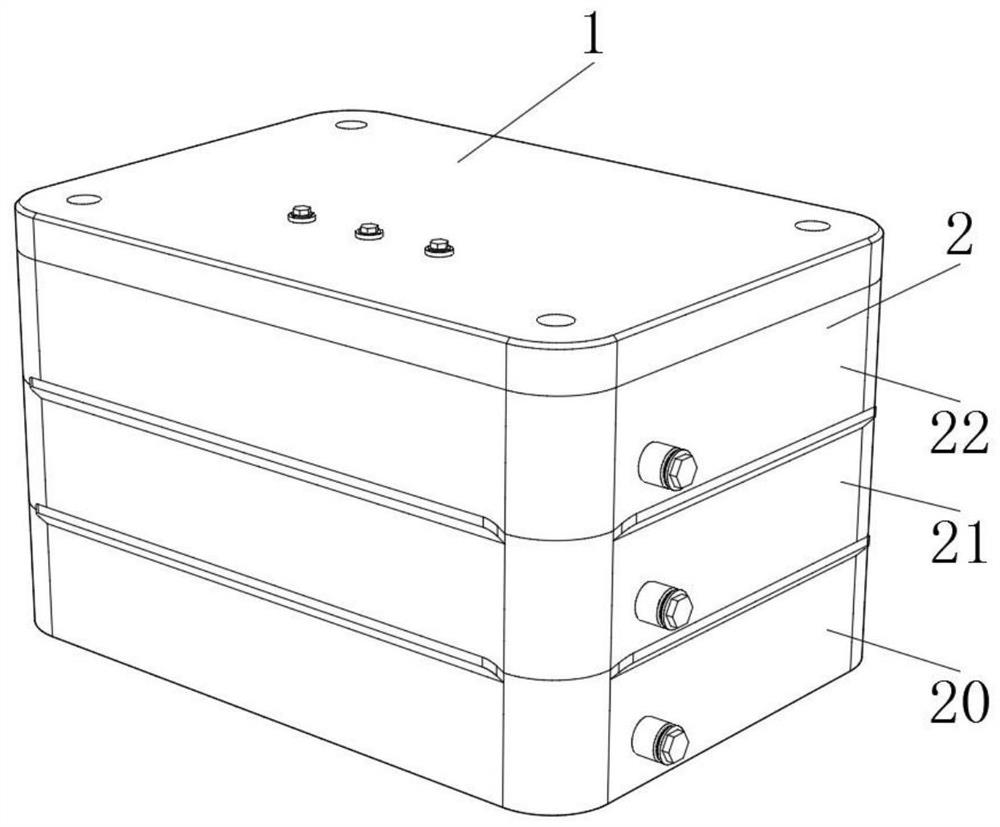

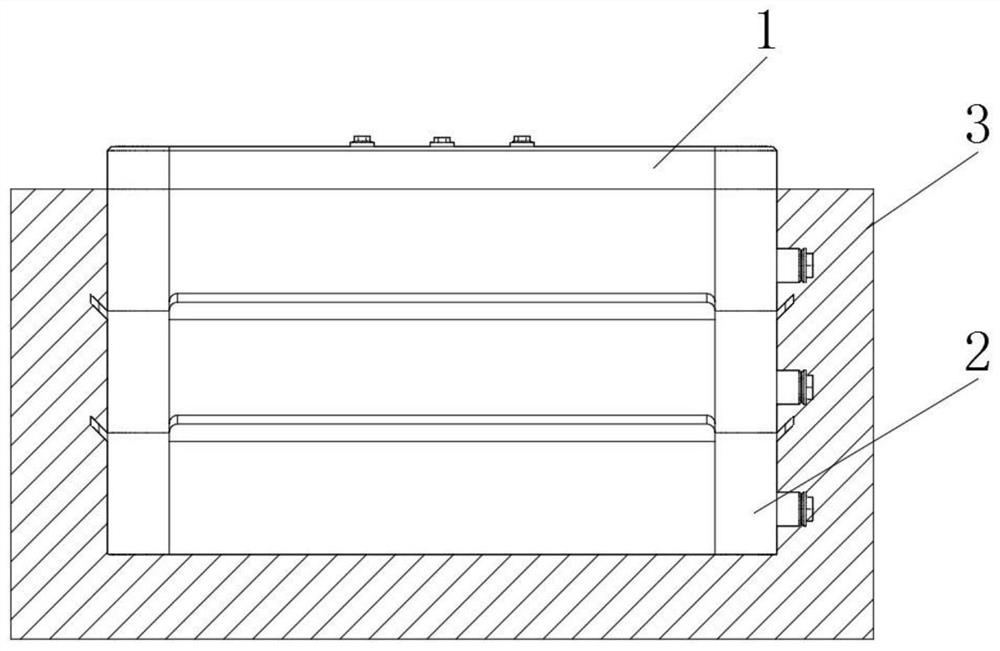

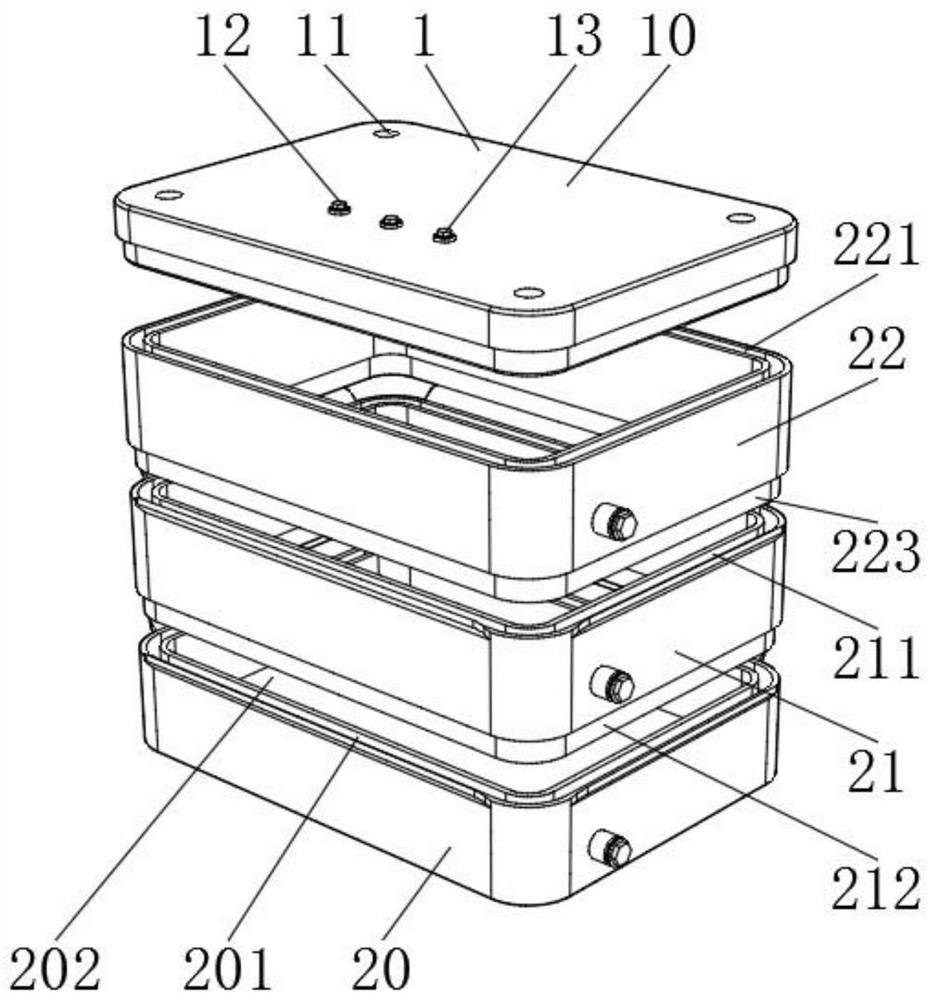

[0045] see Figure 1-9 As shown, a new type of cellar sealing device and its application, including a stainless steel cellar cover 1, an overlapping stainless steel base 2 and a cellar 3, the outer side of the overlapping stainless steel base 2 and the inner side of the cellar 3 are fixedly installed, The top of the overlapping stainless steel base 2 is movably installed with the bottom of the stainless steel cellar cover 1, and four suspension ring interfaces 11 are evenly provided on the outside of the top of the stainless steel cellar cover 1, so that the stainless steel cellar cover 1 can be pulled up easily by using a jack. Open the stackable stainless steel base 2, the top side of the stainless steel cellar pool cover 1 is provided with a temperature measuring hole 12, and the other side of the top of the stainless steel cellar pool cover 1 is provided with a vent hole 13, through which the stackable The exhaust gas in the stainless steel base 2 can be extracted, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com