Thixotropy bentonite slurry with high mud-making rate for horizontal crossing well drilling and preparation method thereof

A technology of bentonite slurry and thixotropy, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., to achieve the effects of improved function, low production equipment requirements, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] The present invention also provides a preparation method for preparing a high slurrying rate thixotropic bentonite slurry, the preparation method comprising the following steps:

[0066] A. Preparation of sodium-based bentonite: sodium-based calcium-based bentonite is prepared by a known method to prepare sodium-based bentonite powder;

[0067] B. Preparation of bentonite base slurry: adding the sodium bentonite powder prepared in step A into water, stirring evenly, leaving standstill, hydration, and being mixed with bentonite base slurry;

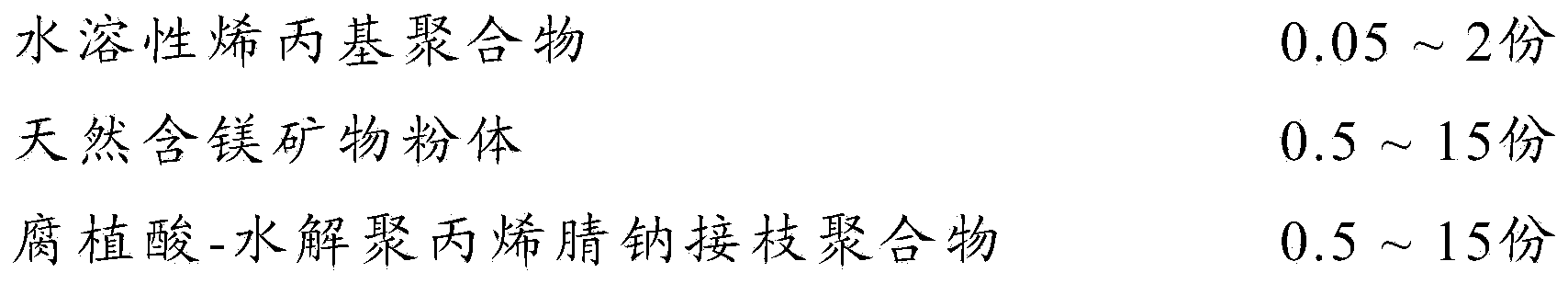

[0068] C. Prepare modifier: mix water-soluble allyl polymer, natural magnesium-containing mineral powder and humic acid-hydrolyzed sodium polyacrylonitrile graft polymer in proportion to make modifier;

[0069] D. Preparation of modified bentonite: Add the modifying agent prepared in step C to the bentonite base slurry prepared in step B, fully stir, and complete the present invention after standing for 10-20 hours.

[0070] Step ...

Embodiment 1

[0108] Take 200g of calcium-based bentonite and pulverize, prepare 50g of 20% sodium carbonate solution, use the above-mentioned raw materials to complete the extrusion and sodiumization of calcium-based bentonite in a single-screw sodium extruder, dry the product and pulverize to obtain sodium-based bentonite powder . Take 25.6g of the above-mentioned sodium bentonite powder and add it into 400mL of water, stir evenly, and let it stand for 16 hours to prepare the bentonite base slurry. Take 0.256g of polyacrylamide, 0.128g of brucite powder, and 1.8g of hydrolyzed polyacrylonitrile sodium salt grafted lignite resin fluid loss reducer (HmPS), and mix them thoroughly to make a modifier. Add the modifier to the bentonite base slurry, stir at high speed for 2 hours and then let it stand for 15 hours.

Embodiment 2

[0110] Add 25.6g of calcium-based bentonite and 1.3g of sodium carbonate into 400mL of water, stir evenly, and let stand for 16 hours to obtain bentonite-based slurry. Take 0.0256g of polyacrylamide, 1.28g of magnesium oxide, and 2.56g of hydrolyzed polyacrylonitrile ammonium salt grafted sulfonated lignite resin fluid loss reducer (KFT-2), and mix them thoroughly to make a modifier. Add the modifier to the bentonite base slurry, stir at high speed for 2 hours and then let it stand for 15 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com