Screen printing ethylene oxide disinfection color shifting printing ink and preparation method

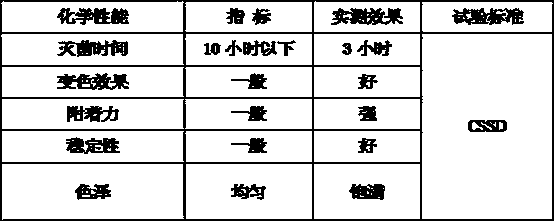

A technology of ethylene oxide and color-changing ink, which is applied in inks, household utensils, applications, etc., can solve the problems of affecting the quality of medical devices, long sterilization time, incomplete discoloration, etc., and achieves short sterilization time and good adhesion Strong, thorough discoloration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] a Take 5 parts of formaldehyde red, 100 parts of ethylene emulsion, 60 parts of alcohol with a concentration of 45%-60%, 6 parts of citric acid, and 8 parts of sodium chloride, and mix to obtain a mixture;

[0030] b. Heating the mixture in step a to 50° C. to obtain the screen printing ethylene oxide sterilized color-changing ink of the present invention.

Embodiment 2

[0032] a Mix 6 parts of formaldehyde red, 200 parts of ethylene emulsion, 70 parts of alcohol with a concentration of 45%-60%, 10 parts of citric acid, and 12 parts of sodium chloride to obtain a mixture;

[0033] b. Heat the mixture in step a to 55° C. to obtain the screen printing ethylene oxide sterilized color-changing ink of the present invention.

[0034] When using the present invention, apply it on the ethylene oxide sterilization indicator card, put the sterilized product into the sterilizer for sterilization, and put the ethylene oxide sterilization indicator card into the sterilizer, After the concentration of ethylene oxide is 600±50ml / 1, the temperature of the sterilizer is 50°C, the humidity is 65%-80%, and it is sterilized for 5 hours. The ethylene oxide sterilization indicator card placed in the sterilizer after 5 hours will change from the initial color to the preset color, for example: the initial color is pink, and the preset color is orange, so that it can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com