Method for extracting parthenolide from plant raw material

A parthenolide, plant raw material technology, applied in bulk chemical production, organic chemistry and other directions, can solve the problems of waste of organic solvents, large environmental pollution, high impurity content, and achieve low cost, simple extraction process and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

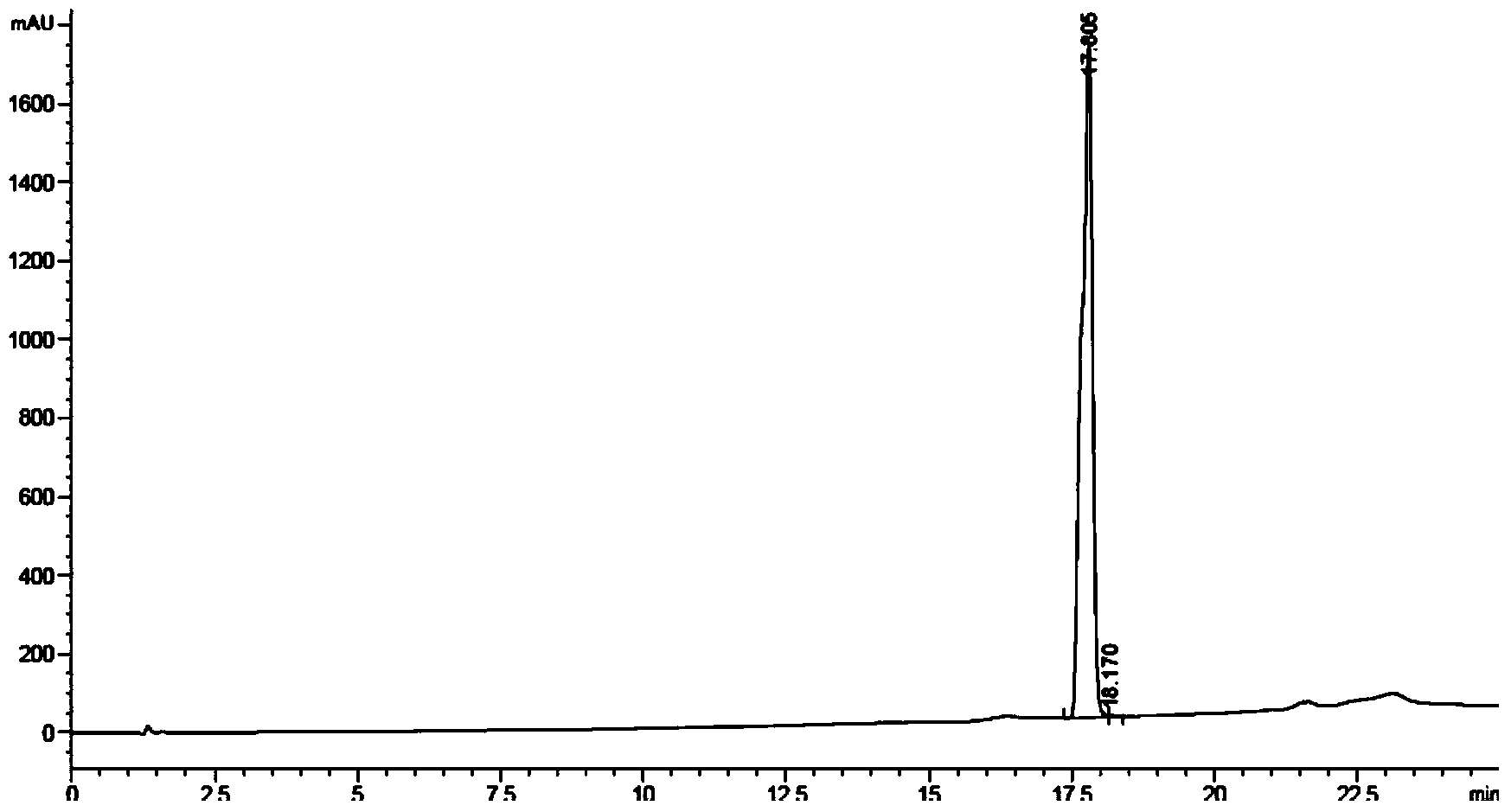

Embodiment 1

[0029] 1) First, the Xiangzi Michelia leaves are naturally dried, crushed, and sifted through a 10-mesh sieve to obtain Xiangzi Michelia leaves powder;

[0030] 2) Set the temperature of the extraction tank to 35°C, the temperature of the separation tank I to 50°C, and the temperature of the separation tank II to 40°C;

[0031] 3) Put the barrel containing 500g of fragrant seeds and smiley leaf powder into the extraction tank and add 500mL of 90% methanol;

[0032] 4) Start the carbon dioxide circulation system, adjust the pressure of the extraction cylinder to 15MPa, the pressure of the separation cylinder I to 10MPa, and the pressure of the separation cylinder II to 6MPa. Adjust the mass flow of carbon dioxide corresponding to each kilogram of raw material (Fragrant Seed and Smile Leaf Powder) to 0.5kg / h. When the temperature and pressure reach the set value, start to record the time. After 1 hour of extraction, the extract is discharged from the discharge port of the separation t...

Embodiment 2

[0039] 1) First, dry the Xiangzi Michelia leaves naturally, smash them, and pass through a 20-mesh sieve to obtain Xiangzi Michelia leaves powder;

[0040] 2) Set the temperature of the extraction tank to 40℃, the temperature of the separation tank I to 55℃, and the temperature of the separation tank II to 45℃;

[0041] 3) Put the barrel containing 700g of fragrant seed and laugh leaf powder into the extraction tank and add 1L of 90% methanol;

[0042] 4) Start the carbon dioxide circulation system, adjust the pressure of the extraction cylinder to 17.5MPa, the pressure of the separation cylinder I to 12.5MPa, and the pressure of the separation cylinder II to 6MPa. Adjust the mass flow of carbon dioxide corresponding to each kilogram of raw material (Fragrant Seed and Smiling Leaf Powder) to 1.0kg / h. When the temperature and pressure reach the set value, start to record the time, and then respectively after 1h, 2h, 4h, release the extract from the discharge port of the separation ta...

Embodiment 3

[0046] 1) First, dry and smash the Xiangzi Michelia leaves, and pass through a 30-mesh sieve to obtain Xiangzi Michelia leaves powder;

[0047] 2) Set the temperature of the extraction tank to 45℃, the temperature of the separation tank I to 60℃, and the temperature of the separation tank II to 50℃;

[0048] 3) Put the barrel containing 1kg of fragrant seeds and laughing leaf powder into the extraction tank;

[0049] 4) Start the carbon dioxide circulation system, adjust the pressure of the extraction cylinder to 20MPa, the pressure of the separation cylinder I to 15MPa, and the pressure of the separation cylinder II to 6MPa. Adjust the mass flow of carbon dioxide corresponding to each kilogram of raw material (Fragrant Seed and Smiling Leaf Powder) to 1.5kg / h. When the temperature and pressure reach the set value, start to record the time, and then after 1h, 3h, and 5h respectively, release the extract from the discharge port of the separation tank II in three times (extraction tot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com