Method and system for high-efficiency recovery of high-salinity mine water

A technology with high salt content in mine water, applied in mining wastewater treatment, chemical instruments and methods, descaling and water softening, etc., can solve the problems of high operating cost, large floor area, long process flow, etc., and achieve simplified operation Process flow, reduced floor space, good strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

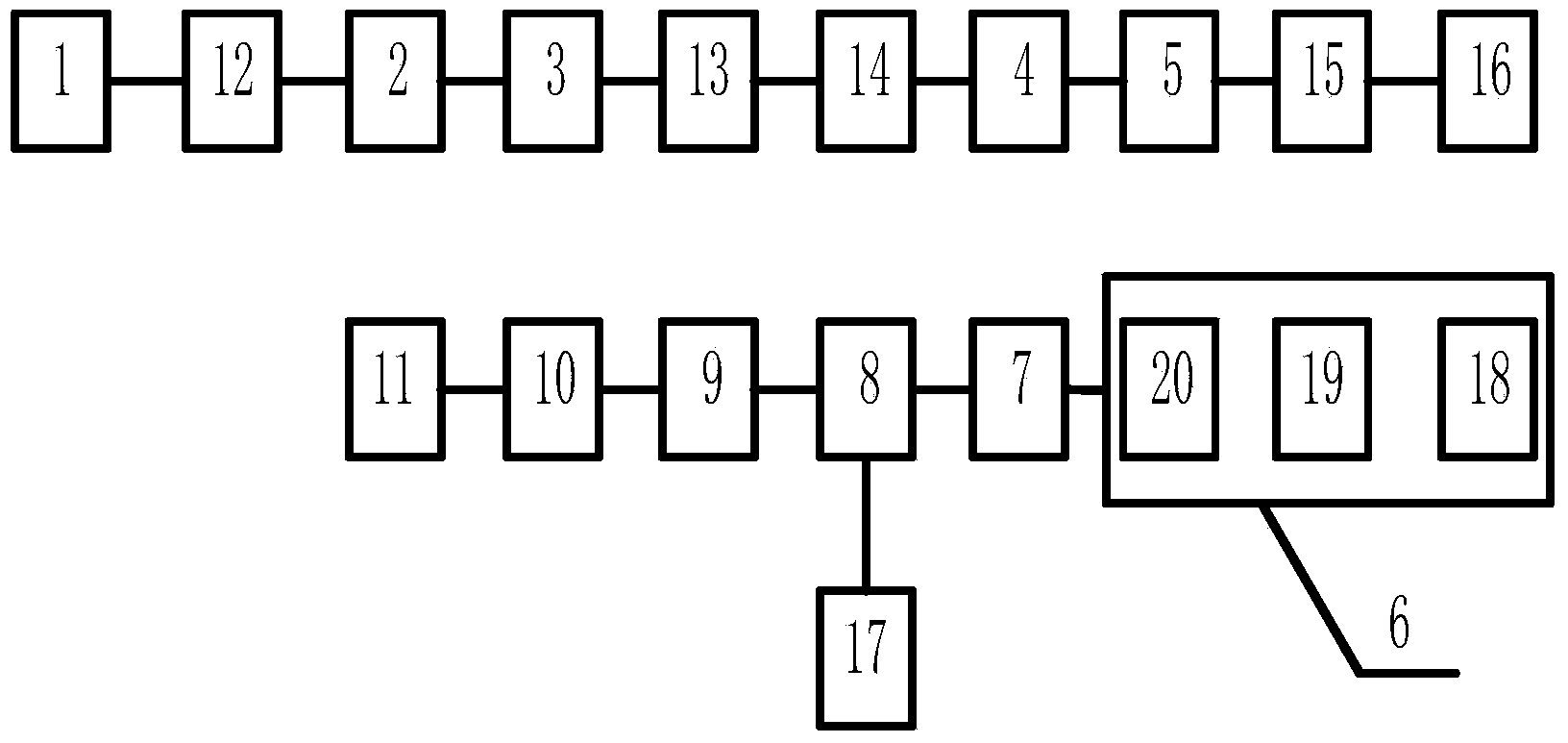

Image

Examples

Embodiment 2

[0286] Example 2: Influent water quality table

[0287] Table 11

[0288]

[0289]

[0290] The characteristics of raw water can be derived from the above table:

[0291] 1. The total hardness is greater than the total alkalinity, and there is permanent hardness. If the lime softening method is used, sodium carbonate must be added.

[0292] 2. Calcium hardness is greater than alkalinity, so sodium hydroxide + sodium carbonate is used for softening to remove calcium in water.

[0293] 3. The concentration of silicon dioxide is relatively high, while the concentration of magnesium ions is relatively low. In order to remove silicon, an appropriate amount of magnesium salt must be added to form a complex of magnesium hydroxide and silicon dioxide, so that magnesium ions carry silicon and precipitate together.

[0294] 4. The sulfate, calcium, and silicon ions in the raw water are very high. When concentrated 5 times, the concentration of calcium sulfate will be 6 times the solubility product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com